Abstract

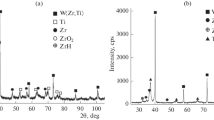

Intermetallic tungsten silicide alloy WSi2–W5Si3 was successfully synthesized via magnesiothermic SHS reaction in the WO3–Si–Mg system. Equilibrium composition of combustion products was calculated by standard Gibbs energy minimization method and the combustion products were characterized by XRD, SEM, and EDX. The synthesized alloy had a density of 8.97 g/cm3 (96.4% of theoretical). The process can be readily recommended for practical implementation.

Similar content being viewed by others

References

Shon, I.J., Rho, D.H., Kim, H.C., and Munir, Z.A., Dense WSi and WSi–20 vol. % ZrO composite synthesized by pressure-assisted field-activated combustion, J. Alloys Comp., 2001, vol. 322, no. 1, pp. 120–126. doi https://doi.org/10.1016/S0925-8388(01)01167-7

Oh, D.Y., Kim, H.C., Yoon, J.K., and Shon, I.J., Simultaneous synthesis and consolidation process of ultra-fine WSi2–SiC and its mechanical properties, J. Alloys Comp., 2005, vol. 386, no. 1, pp. 270–275. doi https://doi.org/10.1016/j.jallcom.2004.05.069

Tao, X., Jund, P., Colinet, C., and Tedenac, J.-C., First-principles study of the structural, electronic and elastic properties of W5Si3, Intermetallics, 2010, vol. 18, no. 4, pp. 688–693. doi https://doi.org/10.1016/j.intermet.2009.11.008

Lawamoto, N. and Uesake, S., Mechanical alloying of transition metal-silicon mixed powder, Mater. Sci. Forum., 1992, vol. 88, pp. 763–770. doi. https://doi.org/10.4028/www.scientific.net/MSF.88-90.763

Petrovic, J.J., High temperature structural silicides, Ceram. Eng. Sci. Proc., 1997, vol. 18, pp. 3–17.

Munir, Z. A., Shon, I.J., and Yamazaki, K., US Patent 5794113, 1998.

Morales, G. and Huang, R., US Patent 6100192, 2000.

Merzhanov, A.G., Combustion processes that synthesize materials, J. Mater. Process. Technol, 1996, vol. 56, nos. 1–4, pp. 222–241. doi https://doi.org/10.1016/0924-0136(95)01837-9

Niyomwas, S., Preparation of aluminum reinforced with TiB2–Al2O3–FexAly composites derived from natural ilmenite, Int. J. Self-Propag. High-Temp. Synth., 2010, vol. 19, no. 2, pp. 150–156. doi https://doi.org/10.3103/S1061386210020111

Sakaki, M., Behnami, A.K., and Bafghi, M.Sh., An investigation of the fabrication of tungsten carbide–alumina composite powder from WO3, Al, and C reactants through microwave-assisted SHS process, Int. J. Refract. Met. Hard Mater, 2014, vol. 44, pp. 142–147. doi https://doi.org/10.1016/j.ijrmhm.2014.02.003

Chanadee, T., Wannasin, J., and Niyomwas, S., Synthesis of WSi2 and W2B intermetallic compound by in-situ self-propagating high-temperature synthesis reaction, J. Ceram. Soc. Jpn, 2014, vol. 122, no. 60, pp. 496–501. doi https://doi.org/10.2109/jcersj2.122.496

Romero, F.J.N., Synthesis of a (WSi2, W5Si3)–SiC composite using the reaction between WC and Si, Abstr. Int. Conf. on Composite Materials by ICCM, Paris, 2000, vol. 1, p. 637.

Outokumpu HSC Chemistry® for Windows, version HSC 4.1. Finland, Outokumpu Research Oy, 1999.

Gokcen, N.A. and Reddy, R.G., Thermodynamics, New York: Plenum Press, 1996.

Moore, J. and Feng, H.J., Combustion synthesis of advanced materials, I: Reaction parameters, Prog. Mater. Sci., 1995, vol. 39, nos. 4–5, pp. 243–273. doi https://doi.org/10.1016/0079-6425(94)00011-5

ASTM C373-88(2006): Standard Test Method for Water Absorption, Bulk Density, Apparent Porosity, and Apparent Specific Gravity of Fired Whiteware Products, ASTM International, West Conshohocken, PA, 2006. doi https://doi.org/10.1520/C0373-88R0610.1520/C0373-88R06

Gnesin, B.A., Gnesin, I.B., and Nekrasov, A.N., The interaction of carbon with Mo5Si3 and W5Si3 silicides: Nowotny phase synthesis, Intermetallics, 2013, vol. 41, pp. 82–95. doi https://doi.org/10.1016/j.intermet.2013.04.019

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Maung, S.T.M., Chanadee, T. & Niyomwas, S. Intermetallic WSi2–W5Si3 Alloy by Magnesiothermic SHS Reaction. Int. J Self-Propag. High-Temp. Synth. 28, 50–55 (2019). https://doi.org/10.3103/S1061386219010096

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1061386219010096