Abstract

When acrylic acid (AA) is synthesized from acetylene carbonylation using supported nickel as a heterogeneous catalyst, it is important to select a suitable carrier material. Accordingly, we prepared a series of nickel-loaded catalysts using treated expanded two-dimensional layered vermiculite (2D-VT), NaY, HY, MCM-41, and talcum powder (TP) as carriers. As a result, it was found that the calcined nickel-supported expanded NiO/2D-VT exhibited excellent catalytic performance as a catalyst. The highest yield (83.1%) was obtained. We used XRD, SEM, TEM, BET, FTIR, TGA, ICP and XPS to thoroughly characterize the catalysts. It was found that the two-dimensional layered structure of vermiculite (VT) itself with a hydroxyl structure provides a loading site for the active metal NiO, which promotes the formation of a hydrogen carboxyl group. And the excellent thermal stability of VT inhibits the formation of carbon deposits in the NiO/2D-VT catalyst during the reaction. Compared with other catalysts, the NiO/2D-VT catalyst has significantly less carbon deposits, more cycles are used, and activity decreases more slowly. In addition, we also studied the reasons for the decrease in the activity of the NiO/2D-VT catalyst used repeatedly, and found that the loss of NiO supported on the VT two-dimensional layered structure is the main reason for the catalyst deactivation.

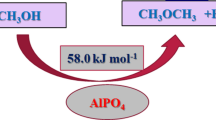

Graphic Abstract

Similar content being viewed by others

References

Corma A (2014) Chem Rev 114:1545–1546

Schobert H (2014) Chem Rev 114:1743–1760

Yan BH, Xu PC, Guo CY, Jin Y, Cheng Y (2012) Chem Eng J 207:109–116

Fu R, Zheng L (2017) J Chem Res 41:341–345

Zhao S, Chen SY, Ma SW, Xiang WG, Song QB (2016) Appl Energy 169:642–651

Tang CM, Zeng Y, Cao P, Yang XG, Wang GY (2009) Catal Lett 129:189–193

Walter R, Robert S (1962) Patent, 3023237

Weissermel K, Arpe HJ (2008) Book

Anastas P, Eghbali N (2010) Chem Soc Rev 39:301–312

Lin TJ, Xie H, Meng X, Shi L (2015) Catal Commun 68:88–92

Lin TJ, Meng X, Shi L (2015) J Mol Catal A 396:77–83

Bhattacharyya SK, Bhattacharyya DP (1966) J Chem Technol Biotechnol 16:18–21

Bhattacharyya SK, Sen AK (1964) Ind Eng Chem Process Des Dev 3:169–176

Bhattacharyya SK, Sen AK (2010) J Chem Technol Biotechnol 13:498–505

Wei H, Mccormick JR, Lobo RF, Chen JG (2007) J Catal 246:40–51

Pereira C, Kokotailo GT, Gorte RJ (1991) J Phys Chem 95:705–709

Xie H, Yi DZ, Shi L, Meng X (2017) Chem Eng J 313:663–670

Lin TJ, Meng X, Shi L (2014) Appl Catal A 485:163–171

Li PP, Wen B, Yu F, Zhu MY, Guo XH, Han Y, Kang LH, Huang X, Dan JM, Ouyang FH, Dai B (2016) Fuel 171:263–269

Zhang K, Yu F, Zhu MY, Dan JM, Wang XG, Zhang JL, Dai B (2018) Catalysts 8:100

Song Q, Altaf N, Zhu MY, Li JB, Ren X, Dan JM, Dai B, Louis B, Wang Q, Yu F (2019) Sustain Energy Fuels 3:965–974

Li PP, Zhu MY, Dan JM, Kang LH, Lai LF, Cai XY, Zhang JS, Yu F, Tian ZQ, Dai B (2017) Chem Eng J 326:774–780

Fu ZL, Liu T, Kong XR, Liu Y, Xu J, Zhang B, Chen HM, Chen ZY (2019) Mater Lett 238:175–178

Li L, Yao J, Fang XY, Huang YX, Mu Y (2017) Sci Rep 7:30–41

Wei H, Li X (2017) Sol Energy Mater Sol Cells 166:1–8

Zhao B, Ke X-K, Bao J-H, Wang C-L, Dong L, Chen Y-W, Chen H-L (2009) J Phys Chem C 113:14440–14447

Tomellini M (1992) J Electron Spectrosc Relat Phenom 58:75–78

Arunachalam P, Ghanem MA, Al-Mayouf A, Alshalwi M, Abd Elkader O (2017) Mater Res Express 4:25–35

Liu JY, Chen T, Jian PM, Wang LX, Yan XD (2018) J Colloid Interface Sci 526:295–301

Węgrzyn A, Stawiński W, Freitas O, Komędera K, Błachowski A, Jęczmionek Ł, Dańko T, Mordarski G, Figueiredo S (2018) Appl Clay Sci 155:37–49

Stawiński W, Węgrzyn A, Mordarski G, Skiba M, Freitas O, Figueiredo S (2018) Appl Clay Sci 161:6–14

Adewuyi A, Oderinde RA (2018) Polym Bull 4:1–23

Chen LY, Wu PG, Chen MQ, Lai XL, Ahmed ZB, Zhu NG, Dang Z, Bi YZ, Liu TY (2018) Appl Clay Sci 159:74–82

Liu YF, He ZH, Zhou L, Hou ZS, Eli WM (2013) Catal Commun 42:40–44

Liu NW, Xie H, Cao HX, Shi L, Meng X (2019) Fuel 242:617–623

Acknowledgements

The work was supported by National Natural Science Foundation of China (No. 21666033), Yangtze River Scholar Research Project of Shihezi University (No. CJXZ201601), and International Science and Technology Cooperation Project of Bingtuan (No. 2018BC002), International Science and Technology Cooperation Project of Shihezi Univeristy (No. GJHZ201804). Competing financial interests the authors declare no conflicts of interests.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, G., Guo, D., Shang, H. et al. Expanded Two-Dimensional Layered Vermiculite Supported Nickel Oxide Nanoparticles Provides High Activity for Acetylene Carbonylation to Synthesize Acrylic Acid. Catal Lett 150, 674–682 (2020). https://doi.org/10.1007/s10562-019-02985-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-02985-3