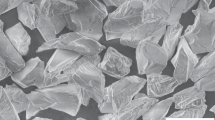

We study the influence of composition and technological conditions on the synthesis of cordierite ceramics from raw materials with origin in the Russian Federation. The structure, porosity, density, and basic thermomechanical properties of cordierite ceramics are investigated with the use of the x-ray phase diffraction and petrographic analyses. Under the industrial conditions, we produced a material containing 85 – 87 wt.% of cordierite and satisfying the requirements to the production of large-size details of catalysts.

Similar content being viewed by others

References

E. G. Avvakumov and A. A. Gusev, Cordierite is a Promising Ceramic Material [in Russian], RAS, Moscow (1999).

V. I. Vanchurin, T. Li, G. M. Semenov, et al., Sorbent with honeycomb structure used to capture platinoids, Khim. Promyshl., No. 10, 581 – 583 (1995).

V. I. Vanchurin, E. A. Brushtein, G. M. Semenov, et al., Distributing attachment with honeycomb structure for the process of oxidation of ammonia, Khim. Promyshl., No. 10, 584 – 586 (1995).

M. D. Gasparyan, V. N. Grunskii, M. G. Davidkhanova, et al., Synthesis of polyfunctional high-porosity block-cellular materials based on the oxide ceramics, Ogneupor. Tekh. Keram., No. 6, 3 – 8 (2016).

A. I. Leonov, O. L. Smorygo, A. N. Romashko, et al., Comparative estimation of the properties of block carriers with honeycomb and cellular structures from the viewpoint of their application in the processes of catalytic purification of gases, Kinet. Katal., 39(5), 691 – 700 (1998).

E. A. Brushtein, V. I. Vanchurin, and A. V. Yashchenko, Prospects of the development of two-stage catalytic systems for the oxidation of ammonia in the production of nitric acid, Katal. Promyshl., No. 6, 47 – 52 (2012).

A. A. Dabizha, N. A. Dabizha, S. F. Shmot’ev, and V. A. Cheremisinov, A Charge for the Production of Cordierite [in Russian], Patent 2040511, Russian Federation, MPK S 04 V 35/18, No. 94007016/33; claimed on 28.02.1994; publ. on 25.07.1995.

T. A. Khabas, E. A. Kostyanaya, V. I. Vereshchagin, A. P. Il’in, A. A. Kirchanov, and T. V. Vakalova, Composition of a Charge for the Production of Cordierite Ceramics [in Russian], Patent 2211199, Russian Federation, MPK S 04 V 35/18, No. 2002111817/03; claimed on 30.04.2002; publ. on 27.08.2003, Byull. No. 24.

E. F. Krivoshapkina, P. V. Krivoshapkin, and B. N. Dudkin, Microporous ceramics with the cordierite composition on the basis of natural raw materials, Izv. Komi Nauch. Tsentr. UrO RAN, No. 3(7), 27 – 32 (2011).

J. A. Hedvall, Einführung in die Festkörperchemie, Fr. Vieweg und Sohn, Braunschweig (1952).

E. S. Lukin, Yu. A. Mazalov, N. A. Popova, and A. V. Fedotov, Application of nanocrystalline boehmite to the technology of substrates of microcircuits, Nanotekhnika, No. 2, 63 – 66 (2010).

E. G. Avvakumov, G. G. Lepezin, D. V. Gorbachev, and O. B. Vinokurova, Influence of mechanical activation on the synthesis of cordierite from talc and minerals from the sillimanite group, Ogneupor. Tekh. Keram., Nos. 1/2, 57 – 61 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 8, pp. 49 – 54, August, 2019.

Rights and permissions

About this article

Cite this article

Vanchurin, V.I., Fedotov, A.V., Belyakov, A.V. et al. Technology of Cordierite Ceramics for the Production of Catalysts. Refract Ind Ceram 60, 399–404 (2019). https://doi.org/10.1007/s11148-019-00375-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-019-00375-1