Abstract

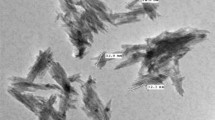

Nanofluids are widely used in heat transfer applications. This article presents the effect of heat transfer and pressure drop of the TiO2–water nanofluids flowing in a double-tube counter-flow heat exchanger with various flow patterns. In this experimental work, performance of TiO2–water nanofluid on heat transfer in three different cases such as laminar, transition and turbulent flow region were analyzed. TiO2 nanoparticles with average diameters of 20 nm dispersed in water with three volume concentrations of 0.1, 0.3 and 0.5 vol% were used as the test fluid. The results show that the heat transfer of nanofluids is higher than that of the base liquid (water) and increased with the increase in Reynolds number and particle concentrations. The heat transfer rate of nanofluid with 0.5 vol% was 25% greater than that of base liquid, and the results also show that the heat transfer coefficient of the nanofluids at a volume concentration of 0.5 vol% was 15% higher than that of base fluid at given conditions. Pressure drop of nanofluid was increased with increase in volume concentration, and it is slightly higher than that of the base fluid.

Similar content being viewed by others

Abbreviations

- A :

-

Cross-sectional area (m2)

- C :

-

Specific heat (kJ kg−1 K−1)

- D :

-

Internal diameter of the tube (m)

- K :

-

Thermal conductivity (W m−1 K−1)

- T :

-

Temperature (K)

- m :

-

Mass flow rate (kg s−1)

- Q :

-

Heat transfer rate (W)

- Nuave :

-

Average Nusselt number

- h :

-

Heat transfer coefficient (W m−1 K−1)

- Re:

-

Reynolds number

- Nu:

-

Nusselt number

- g :

-

Acceleration dew to gravity (m s−2)

- H :

-

Difference of pressure head (m)

- f :

-

Friction factor

- L :

-

Length of the heat exchanger (m)

- ρ nf :

-

Density of nanofluid (kg m−3)

- ρ f :

-

Density of base fluid (kg m−3)

- ρ p :

-

Density of nanoparticle (kg m−3)

- \((C_{\text{p}})_{\text{nf}}\) :

-

Specific heat of nanofluid (kJ kg−1 K−1)

- \((C_{\text{p}})_{\text{f}}\) :

-

Specific heat of base fluid (kJ kg−1 K−1)

- \((C_{\text{p}})_{\text{p}}\) :

-

Specific heat of nanoparticle (kJ kg−1 K−1)

- K nf :

-

Thermal conductivity of nanofluid (W m−1 K−1)

- k p :

-

Thermal conductivity of nanoparticle (W m−1 K−1)

- k f :

-

Thermal conductivity of base fluid (W m−1 K−1)

- μ nf :

-

Dynamic viscosity of nanofluid (kg m−1 s−1)

- μ bf :

-

Dynamic viscosity of base fluid (kg m−1 s−1)

- Q c :

-

Heat transfer of cold fluid (kW)

- Q h :

-

Heat transfer of hot fluid (kW)

- Q w :

-

Heat transfer of base fluid (kW)

- Q nf :

-

Heat transfer of nanofluid (kW)

- Q mean :

-

Average heat transfer of base fluid and nanofluid (kW)

- T ci :

-

Temperature of cold fluid inlet (K)

- T hi :

-

Temperature of hot fluid inlet (K)

- T co :

-

Temperature of cold fluid outlet (K)

- T ho :

-

Temperature of hot fluid outlet (K)

- h nf :

-

Convective heat transfer coefficient of nanofluid (kW m−2 K−1)

- ρ ccl4 :

-

Density of carbon tetra chloride (Kg m−3)

- μ :

-

Dynamic viscosity (kg m−1 s−1)

- φ :

-

Volume concentration of nanofluid (%)

- ρ :

-

Density (kg m−3)

- ∆p :

-

Pressure drop (N m−2)

- i:

-

Inner tube or inlet

- c:

-

Cold fluid

- h:

-

Hot water

- f:

-

Base fluid

- p:

-

Particle

- nf:

-

Nanofluids

References

Duangthongsuk W, Wongwises S. Heat transfer enhancement and pressure drop characteristics of TiO2–water nanofluid in a double-tube counter flow heat exchanger. Int J Heat Mass Transf. 2009;52(7):2059–67. https://doi.org/10.1016/j.ijheatmasstransfer.2008.10.023.

Arabpour A, Karimipour A, Toghraie D. The study of heat transfer and laminar flow of kerosene/multi-walled carbon nanotubes (MWCNTs) nanofluid in the microchannel heat sink with slip boundary condition. J Therm Anal Calorim. 2018;131(2):1553–66. https://doi.org/10.1007/s10973-017-6649-x.

Hemmat EM, Hassani AMR, Toghraie D, Hajmohammad MH, Rostamian H, Tourang H. Designing artificial neural network on thermal conductivity of Al2O3–water–EG (60–40%) nanofluid using experimental data. J Therm Anal Calorim. 2016;126:837–43.

Afshari A, Akbari M, Toghraie D, Yazdi ME. Experimental investigation of rheological behavior of the hybrid nanofluid of MWCNT-alumina/water (80%)-ethylene-glycol (20%). J Therm Anal Calorim. 2018;132(2):1001–15. https://doi.org/10.1007/s10973-018-7009-1.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Siavashi M, Taylor RA, Niazmand H, Wongwises S, Hayat T, Kolanjiyil A, Kasaeian A, Pop I. Recent advances in modeling and simulation of nanofluid flows—part I: fundamentals and theory. Phys Rep. 2018. https://doi.org/10.1016/j.physrep.2018.11.004.

Esfahani NN, Toghraie D, Afrand M. A new correlation for predicting the thermal conductivity of ZnO–Ag (50%–50%)/water hybrid nanofluid: an experimental study. Powder Technol. 2018;323:367–73.

Chun BH, Kang HU, Hyun KS. Effect of alumina nanoparticles in the fluid on heat transfer in double pipe heat exchanger system. Korean J Chem Eng. 2008;25:966–71. https://doi.org/10.1007/s11814-008-0156-5.

Muthusamy V, Skryabin S. Effect of conical cut-out turbulators with internal fins in a circular tube on heat transfer and friction factor. Int Commun Heat Mass Transf. 2013;44:64–8. https://doi.org/10.1016/j.icheatmasstransfer.2013.03.004.

Zadkhast M, Toghraie D, Karimipour A. Developing a new correlation to estimate the thermal conductivity of MWCNT-CuO/water hybrid nanofluid via an experimental investigation. J Therm Anal Calorim. 2017;129(2):859–67. https://doi.org/10.1007/s10973-017-6213-8.

Rabienataj DA, Farhadi M, Sedighi K. Heat transfer and flow characteristics of Al2O3–water nanofluid in a double tube heat exchanger. Int Commun Heat Mass Transf. 2013;47:105–12. https://doi.org/10.1016/j.icheatmasstransfer.2013.06.003.

Aghayari R, Maddah H, Ashori F, Hakiminejad A, Aghili M. Effect of nanoparticles on heat transfer in mini double pipe heat exchangers in turbulent flow. Heat Mass Transf. 2013. https://doi.org/10.1007/s00231-014-1415-0.

Reddy MCS, Rao VV. Experimental investigation of heat transfer coefficient and friction factor of ethylene glycol water based TiO2 nanofluid in double pipe heat exchanger with and without helical coil inserts. Int Commun Heat Mass Transf. 2014;50:68–76. https://doi.org/10.1016/j.icheatmasstransfer.2013.11.002.

Khedkar R, Sonawane SS, Wasewar KL. Heat transfer study on concentric tube heat exchanger using TiO2–water-based nanofluid. Int Commun Heat Mass Transf. 2014. https://doi.org/10.1016/j.icheatmasstransfer.2014.07.011.

Muthusamy C, Gowtham M, Manickam S, Manjunathan M, Srithar K. Enhancement of productivity of humidification–dehumidification desalination using modified air heater. Desalination Water Treat. 2015;56(12):3294–304. https://doi.org/10.1080/19443994.2014.968876.

Esfe MH, Hajmohammad H, Toghraie D, Rostamian H, Mahian O, Wongwises S. Multi-objective optimization of nanofluid flow in double tube heat exchangers for applications in energy systems. Energy. 2017;137:160–71. https://doi.org/10.1016/j.energy.2017.06.104.

Hosseinnezhad R, Akbari OA, Afrouzi HH, Biglarian M, Koveiti A, Toghraie D. Numerical study of turbulent nanofluid heat transfer in a tubular heat exchanger with twin twisted-tape inserts. J Therm Anal Calorim. 2018;132(1):741–59. https://doi.org/10.1007/s10973-017-6900-5.

Pak BC, Cho YI. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf. 1998;11:151–70.

Freidoonimehr N, Rostami B, Rashidi MM, Omoniat E. Analytical modelling of three-dimensional squeezing nanofluid flow in a rotating channel on a lower stretching porous wall., Mathematical Problems in EngineeringLondon: Hindawi Publishing Corporation; 2014. p. 1–14. https://doi.org/10.1155/2014/692728.

Ding Y, Alias H, Wen D, Williams RA. Heat transfer of aqueous suspensions of carbon nanotubes (CNT nanofluids). Int J Heat Mass Transf. 2005;49:240–50. https://doi.org/10.1016/j.ijheatmasstransfer.2005.07.009.

Sarafraz MM, Hormozi F, Nikkhah V. Thermal performance of a counter-current double pipe heat exchanger working with COOH-CNT/water nanofluids. Exp Therm Fluid Sci. 2016;78:41–9. https://doi.org/10.1016/j.expthermflusci.2016.05.014.

Diao Y, Li CZ, Zhang J, Zhao Y, Kang Y. Experimental investigation of MWCNT-water nanofluids flow and convective heat transfer characteristics in multiport minichannels with smooth/micro-fin surface. Powder Technol. 2017;305:206–16. https://doi.org/10.1016/j.powtec.2016.10.011.

Duangthongsuk W, Wongwises S. An experimental study on the heat transfer performance and pressure drop of TiO2–water nanofluids flowing under a turbulent flow regime. Int J Heat Mass Transf. 2010;53(1–3):334–44. https://doi.org/10.1016/j.ijheatmasstransfer.09.024.

Rohit K, Shriram S, Kailas W. Heat transfer study on concentric tube heat exchanger using TiO2–water-based nanofluids. Int Commun Heat Mass Transf. 2014;57:163–9.

Murshed SMS, Leong KC, Yang C. Enhanced thermal conductivity of TiO2—water based nanofluids. Int J Therm Sci. 2005;44(4):363–73. https://doi.org/10.1016/j.ijthermalsci.2004.12.005

Ma Y, Mohebbi R, Rashidi ZY. Study of nanofluid forced convection heat transfer in a bent channel by means of lattice Boltzmann method. Phys Fluids. 2018;30:032001–13. https://doi.org/10.1063/1.5022060.

Rashidi MM, Bhatti MM, Abbas MA, Ali ME-S. Entropy generation on MHD blood flow of nanofluid due to peristaltic waves. Entropy. 2016;18(117):1–16. https://doi.org/10.3390/e18040117.

Ali Abbas M, Bai YQ, Rashidi MM, Bhatti MM. Application of drug delivery in magnetohydrodynamics peristaltic blood flow of nanofluid in a non-uniform channel. J Mech Med Biol. 2016;16(4). https://doi.org/10.1142/S0219519416500524.

Makulati N, Kasaeipoor A, Rashidi MM. Numerical study of natural convection of a water–alumina nanofluid in inclined C-shaped enclosures under the effect of magnetic field. Adv Powder Technol. 2016;27(2):661–72. https://doi.org/10.1016/j.apt.2016.02.020.

Kasaeian A, Daneshazarian R, Mahian O, Kolsi L, Chamkha A, Wongwises S, Pop I. Nanofluid flow and heat transfer in porous media: a review of the latest developments. Heat Mass Transf. 2017;107:778–91. https://doi.org/10.1016/j.ijheatmasstransfer.2016.11.074.

Karimipour-Fard P, Afshari E, Ziaei-Rad M, Taghian-Dehaghani S. A numerical study on heat transfer enhancement and design of a heat exchanger with porous media in continuous hydrothermal flow synthesis system. Chin J Chem Eng. 2017. https://doi.org/10.1016/j.cjche.2017.01.015.

Syam Sundar L, Sharma KV, Singh MK, Sousa ACM. Hybrid nanofluids preparation, thermal properties, heat transfer and friction factor—a review. Renew Sustain Energy Rev. 2017. https://doi.org/10.1016/j.rser.2016.09.108.

Naseema SK, NawazishMehdia S, Hussain MM, Basha SK, Samad MA. Heat enhancement of heat exchanger using aluminium oxide (Al2O3), copper oxide (CUO) nanofluids with different concentrations. Mater Today Proc. 2018;5(2):6481–8. https://doi.org/10.1016/j.matpr.2017.12.261

Phanindra Y, Kumar SD, Pugazhendhi S. Experimental investigation on Al2O3 & Cu/Oil hybrid nano fluid using concentric tube heat exchanger. Mater Today Proc. 2018;5(2):12142–50. https://doi.org/10.1016/j.matpr.2018.02.192.

Moradi A, Toghraie D, Isfahani AHM, Hosseinian A. An experimental study on MWCNT-water nanofluids flow and heat transfer in double-pipe heat exchanger using porous media. J Therm Anal Calorim. 2019;1:21. https://doi.org/10.1007/s10973-019-08076-0.

Suresh S, Chandrasekar M, Chandrasekhar S. Experimental studies on heat transfer and friction factor charecteristics of Cuo/water nanofluid under turbulent flow in a helically dimpled tube. Exp Therm Fluid Sci. 2011;35:542–9.

Xuan Y, Roetzel W. Conceptions for heat transfer correlations of nanofluids. Int J Heat Mass Transf. 2000;43:3701–7.

Brinkman H. The viscosity of concentrated suspensions and solutions. J Chem Phys. 1952;20:571–82.

Kakac S, Liu H. Heat exchangers: selection, rating, and thermal design. 2nd ed. CRC Press; 2002. p. 131–227.

Swamee PK, Aggarwal N. Optimum design of double pipe heat exchanger. Int J Heat Mass Transf. 2008;51:2260–6.

Bell KJ. Final report of the cooperative research program on shell and tube heat exchangers. Engineering Experiment Station Bulletin. University of Delaware; 1963.

Rohsenow WM, Hartnett JR, Cho YI. Chapter 5: Forced convection, internal flow in ducts. In: Handbook of Heat Transfer. 3rd ed. New York: McGraw-Hill; 1944.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Subramanian, R., Senthil Kumar, A., Vinayagar, K. et al. Experimental analyses on heat transfer performance of TiO2–water nanofluid in double-pipe counter-flow heat exchanger for various flow regimes. J Therm Anal Calorim 140, 603–612 (2020). https://doi.org/10.1007/s10973-019-08887-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08887-1