Abstract

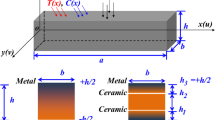

Plate forming is an essential procedure in shipbuilding, which will influence the dimensional accuracy and fabrication schedule. Due to the advantages of induction heating for plate forming such as precision controlling, high level of automation, an experimental investigation for plate forming with multiple linear induction heating was carried out at first. With advanced 25 kW induction heating equipment and additional water cooling system, thermal cycles of several examined points during plate forming with induction heating was measured, and the influence of moving speed of induction heating coil on highest temperature of examined points was also investigated. Applying different heating pattern, plate with 6 mm in thickness will buckle as saddle shape due to the multiple-line heating in longitudinal direction and its generated large enough compressive force. Moreover, thermal elastic plastic (TEP) FE and elastic FE computational approaches were proposed and employed. Predicted out-of-plane bending deformations both have good agreement with measurement. Elastic FE computation with bending moment caused by induction heating as input load has effective advantage and high accuracy comparing to conventional thermal elastic plastic FE computation.

Similar content being viewed by others

References

Jang CD, Kim HK, Ha YS (2002) Prediction of plate bending by high-frequency induction heating. J Ship Prod 18(4):226–236

Shen H, Yao ZQ, Shi YJ et al (2006) Study on temperature field induced in high frequency induction heating. Acta Metal Sin 19(3):190–196

Zhang X, Liu Y, Yang Y et al (2011) Technical parameter analysis of high-frequency induction heating applied to steel plate bending. J Ship Prod Des 27(27):99–110

Lee KS, Eom DH, Lee JH (2013) Deformation behavior of SS400 Thick plate by high-frequency induction heating based line heating. Metals Mater Int 19(2):315–328

Lee KS, Kim SW, Eom DH (2015) Temperature distribution and bending behavior of thick metal plate by high frequency induction heating. Mater Res Innov 15(sup1):283–287

Bae KY, Yang YS, Hyun CM (2012) Analysis of triangle heating technique using high frequency induction heating in forming process of steel plate. J Precis Eng Manuf 13(4):539–545

Lee KS, Hwang B (2014) An approach to triangular induction heating in final precision forming of thick steel plates. J Mater Process Tech 214(4):1008–1017

Park DH, Jin HK, Park SS, Shin SB (2015) A study on the prediction of the angular distortion in line heating with high frequency induction heating. J Weld Join 33(1):80–86

Park J, Kim D, Mun SH et al (2016) Automated thermal forming of curved plates in shipbuilding: system development and validation. Int J Comput Integr Manuf 29(10):1128–1145

Zhang S, Liu C, Wang X et al (2018) Non-dimensional prediction of thermal forming behavior for the ship hull plate fabricated by induction heating. Ships Offshore Struct 14:1–13

Wang JC, Huang WJ, Chang LC et al (2017) Elastic FE analysis on plate forming of pillow shape by line heating. Mar Technol 4:14–17

Rudnev V, Loveless D, Cook RL, Black M (2017) Handbook of induction heating, 2nd edn. CRC Press, Boca Raton

Hocken RJ, Pereira PH (2016) Coordinate measuring machines and systems. CRC Press, Boca Raton

Wang JC, Rashed S, Murakawa H (2014) FE analysis of buckling behavior caused by welding in thin plates of high tensile strength steel. J Mater Eng Perform 23(12):4358–4365

Ma N, Wang JC, Okumoto Y (2016) Out-of-plane welding distortion prediction and mitigation in stiffened welded structures. Int J Adv Manuf Technol 84(5):1371–1389

Wang JC, Ma N, Murakawa H (2015) An efficient FE computation for predicting welding induced buckling in production of ship panel structure. Mar Struct 41:20–52

Wang JC, Zhao H, Zou J et al (2017) Welding distortion prediction with elastic FE analysis and mitigation practice in fabrication of cantilever beam component of jack-up drilling rig. Ocean Eng 130:25–39

Wang JC, Yi B, Zhou H (2018) Framework of computational approach based on inherent deformation for welding buckling investigation during fabrication of lightweight ship panel. Ocean Eng 157:202–210

Wang JC, Rashed S, Murakawa H et al (2013) Numerical prediction and mitigation of out-of-plane welding distortion in ship panel structure by elastic FE analysis. Mar Struct 34:135–155

Wang JC, Shibahara M, Zhang X, Murakawa H (2012) Investigation on twisting distortion of thin plate stiffened structure under welding. J Mater Process Technol 212(8):1705–1715

Wang J, Yin X, Murakawa H (2013) Experimental and computational analysis of residual buckling distortion of bead-on-plate welded joint. J Mater Process Technol 213(8):1447–1458

Wang JC, Rashed S, Murakawa H (2014) Mechanism investigation of welding induced buckling using inherent deformation method. Thin-Walled Struct 80:103–119

Acknowledgements

The authors appreciate the financial support provided by Marine Equipment and Technology Institute, Jiangsu University of Science and Technology (No: HZ20180002), and the National Natural Science Foundation of China (Grant No: 51609091).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

About this article

Cite this article

Zhou, H., Yi, B., Wang, J. et al. Preliminary investigation on plate bending with multiple-line induction heating. J Mar Sci Technol 25, 455–466 (2020). https://doi.org/10.1007/s00773-019-00653-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00773-019-00653-0