Abstract

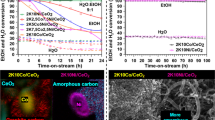

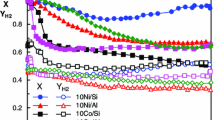

Steam reforming of toluene, a model tar compound, was carried out at low temperature of 600 °C using Cu–Ni and Fe–Ni bimetallic catalysts with different molar ratios supported on activated carbon (AC). For the Cu–Ni/AC catalysts, the carbon conversion of toluene rose and then decreased with the content of Cu increasing, and the best performance was achieved at the molar ratio of 0.2. However, the Fe–Ni/AC catalyst with the optimum composition of Fe/Ni = 0.1 had a better catalytic performance for toluene steam reforming than the Cu–Ni/AC catalyst (Cu/Ni = 0.2). During the duration test of 20 h, the Fe–Ni/AC (Fe/Ni = 0.1) catalyst showed higher activity for the average carbon conversion of toluene (93.8% vs. 92.9%) and better resistance. to carbon deposition than those of Ni/AC catalyst. Moreover, the metal average sizes of the spent Ni/AC and 0.1-Fe–Ni/AC were estimated to be 30.0 nm and 19.0 nm, respectively. Based on a variety of physiochemical characterization results, it is demonstrated that the addition of iron into Ni/AC catalyst led to good dispersion of Ni, and few coke formation and limited aggregation of nickel particles during reaction.

Similar content being viewed by others

References

Yang XQ, Liu XJ, Liu HX, Yue XM, Cao JP, Zhou M (2014) Synergy effect in co-gasification of lignite and char of pine sawdust. Acta Phys–Chim Sin (Chinese) 30:1794–1800

Kumar A, Jones DD, Hanna MA (2009) Thermochemical biomass gasification: a review of the current status of the technology. Energies 2:556–581

Kumar SM, Madhu GM, Roy S (2007) Fouling behaviour, regeneration options and on-line control of biomass-based power plant effluents using microporous ceramic membranes. Sep Purif Technol 57:25–36

Baumhakl C, Karellas S (2011) Tar analysis from biomass gasification by means of online fluorescence spectroscopy. Opt Laser Eng 49:885–891

Ashok J, Kawi S (2014) Nickel–iron alloy supported over iron–alumina catalysts for steam reforming of biomass tar model compound. ACS Catal 4:289–301

Anis S, Zainal ZA (2001) Tar reduction in biomass producer gas via mechanical, catalytic and thermal methods: a review. Renew Sustain Energy Rev 15:2355–2432

Han J, Kim H (2008) The reduction and control technology of tar during biomass gasification/pyrolysis: an overview. Renew Sustain Energy Rev 12:397–416

Shen YF, Yoshikawa K (2013) Recent progresses in catalytic tar elimination during biomass gasification or pyrolysis—a review. Renew Sustain Energy Rev 21:371–392

Asadullah M (2014) Barriers of commercial power generation using biomass gasification gas: a review. Renew Sustain Energy Rev 29:201–215

Chan FL, Tanksale A (2014) Review of recent developments in Ni-based catalysts for biomass gasification. Renew Sustain Energy Rev 38:428–438

Al-Rahbi AS, Williams PT (2017) Hydrogen-rich syngas production and tar removal from biomass gasification using sacrificial tyre pyrolysis char. Appl Energy 190:501–509

Schmidt S, Giesa S, Drochner A, Vogel H (2011) Catalytic tar removal from bio syngas—catalyst development and kinetic studies. Catal Today 175:442–451

Kaewpanha M, Guan GQ, Hao XG, Wang ZD, Kasai Y, Kakuta S, Kusakabe K, Abudula A (2013) Steam reforming of tar derived from the steam pyrolysis of biomass over metal catalyst supported on zeolite. J Taiwan Inst Chem E 44:1022–1026

Baker EG, Mudge LK, Brown MD (1987) Steam gasification of biomass with nickel secondary catalysts. Ind Eng Chem Res 26:1335–1339

Sutton D, Kelleher B, Ross JRH (2001) Review of literature on catalysts for biomass gasification. Fuel Process Technol 73:155–173

Srinakruang J, Sato K, Vitidsant T, Fujimoto K (2005) A highly efficient catalyst for tar gasification with steam. Catal Commun 6:437–440

Artetxe M, Nahil MA, Olazar M, Williams PT (2016) Steam reforming of phenol as biomass tar model compound over Ni/Al2O3 catalyst. Fuel 184:629–636

Qian KZ, Kumar A (2017) Catalytic reforming of toluene and naphthalene (model tar) by char supported nickel catalyst. Fuel 187:128–136

Arteaga-Pérez LE, Delgado AM, Flores M, Olivera P, Matschuk K, Hamel C, Schulzke T, Jiménez R (2018) Catalytic conversion of model tars over carbon-supported Ni and Fe. Catalysts 8:119–136

Hu M, Laghari M, Cui BH, Xiao B, Zhang BP, Guo DB (2018) Catalytic cracking of biomass tar over char supported nickel catalyst. Energy 145:228–237

Liu XJ, Yang XQ, Liu C, Chen C, Yue XM, Zhang SQ (2016) Low-temperature catalytic steam reforming of toluene over activated carbon supported nickel catalysts. J Taiwan Inst Chem E 65:233–241

Chaiprasert P, Vitidsant T (2009) Effects of promoters on biomass gasification using nickel/dolomite catalyst. Korean J Chem Eng 26(6):1545–1549

Wang L, Li D, Koike M, Koso S, Nakagawa Y, Xu Y, Tomishige K (2011) Catalytic performance and characterization of Ni-Fe catalysts for the steam reforming of tar from biomass pyrolysis to synthesis gas. Appl Catal A: Gen 392:248–255

Bambal AS, Vecchio KS, Cattolica RJ (2014) Catalytic effect of Ni and Fe addition to gasifier bed material in the steam reforming of producer gas. Ind Eng Chem Res 53:13656–13666

Wang XL, Pan XM, Lin R, Kou S, Zou WB, Ma JX (2010) Steam reforming of dimethyl ether over Cu–Ni/γ-Al2O3 bi-functional catalyst prepared by deposition–precipitation method. Int J Hydrog Energy 35:4060–4068

Vizcaino AJ, Carrero A, Calles JA (2007) Hydrogen production by ethanol steam reforming over Cu-Ni supported catalysts. Int J Hydrog Energy 32:1450–1461

Tuan LA, Luong NT, Ishihara KN (2016) Low-temperature catalytic performance of Ni-Cu/Al2O3 catalysts for gasoline reforming to produce hydrogen applied in spark ignition engines. Catalysts 6:45–61

Yang XQ, Xu SP, Xu HL, Liu XD, Liu CH (2010) Nickel supported on modified olivine catalysts for steam reforming of biomass gasification tar. Catal Commun 11:383–386

Świerczyński D, Libs S, Courson C, Kiennemann A (2007) Steam reforming of tar from a biomass gasification process over Ni/olivine catalyst using toluene as a model compound. Appl Catal B Environ 74:211–222

Xie YH, Su YH, Wang P, Zhang SP, Xiong YQ (2018) In-situ catalytic conversion of tar from biomass gasification over carbon nanofibers-supported Fe-Ni bimetallic catalysts. Fuel Process Technol 182:77–87

Shen YF, Zhao PT, Shao QF, Ma DC, Takahashi F, Yoshikawa K (2014) In-situ catalytic conversion of tar using rice husk char-supported nickel-iron catalysts for biomass pyrolysis/gasification. Appl Catal B Environ 152–153:140–151

Fu P, Hu S, Xiang J, Yi W, Bai X, Sun L, Su S (2012) Evolution of char structure during steam gasification of the chars produced from rapid pyrolysis if rice busk. Bioresour Technol 114:691–697

Li DL, Koike M, Chen JH, Nakagawa Y, Tomishige K (2014) Preparation of Ni-Cu/Mg/Al catalysts from hydrotalcite-like compounds for hydrogen production by steam reforming of biomass tar. Int J Hydro Energy 39:10959–10970

Lee JH, Lee EG, Joo OS, Jung KD (2004) Stabilization of Ni/Al2O3 catalyst by Cu addition for CO2 reforming of methane. Appl Catal A Gen 269:1–6

Gheisari K, Javadpour S, Oh JT, Ghaffari M (2009) The effect of milling speed on the structural properties of mechanically alloyed Fe-45%Ni powders. J Alloys Compd 472:416–420

Acknowledgements

The work was supported by the Fundamental Research Funds for the Central Universities (Grant No. 2015XKMS046), and the National Natural Science Foundation of China (Grant No. 21706276).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Yang, X., Liu, X., Guo, T. et al. Effects of Cu and Fe Additives on Low-Temperature Catalytic Steam Reforming of Toluene Over Ni/AC Catalysts. Catal Surv Asia 23, 54–63 (2019). https://doi.org/10.1007/s10563-018-9260-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10563-018-9260-7