Abstract

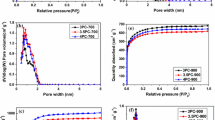

Salacca peel-based porous carbon (SPPC) with high surface area (1945 m2 g−1) and large specific pore volume (1.68 cm3 g−1) was prepared by pre-carbonization and K2CO3 activation method. Based on the TGA results, it can be estimated that up to 70 wt% of sulfur-active materials could be infiltrated into the pores of SPPC to form SPPC/S composite cathode for LiS battery. The porous structure of SPPC could act as a buffer layer against volume expansion and minimize the shuttle effect due to the penetration of intermediate polysulfides during cycle tests. Optimization on sulfur loading (50, 60 and 70 wt%) in SPPCC/S composite was also investigated. It was found that the SPPC/S composites with 60 wt% of sulfur loading had the best electrochemical performances. With 60 wt% of sulfur loading, SPPC/S composite electrodes showed excellent electrochemical performances in terms of high initial specific discharge capacity of 1006 mAh g−1 at 0.5 C and capacity retention of 71% until the 100th cycle. For both cases of low and high sulfur loading, they caused much worse electrochemical performances. Based on the experimental results, it can be concluded that porous carbons derived from the salacca peel were promising materials for sulfur loading in LiS battery.

Similar content being viewed by others

References

Fu C, Guo J (2016) Challenges and current development of sulfur cathode in lithium–sulfur battery. Curr Opin Chem Eng 13:53–62. https://doi.org/10.1016/j.coche.2016.08.004

Fotouhi A, Auger D, O’Neill L et al (2017) Lithium-sulfur battery technology readiness and applications—a review. Energies 10:1937. https://doi.org/10.3390/en10121937

Li C, Wang Z, Wang Q, Gu D (2017) Recent advances in cathode materials for Li–S battery: structure and performance. Rare Met 36:365–380. https://doi.org/10.1007/s12598-017-0900-2

Zeng LC, Li WH, Jiang Y, Yu Y (2017) Recent progress in Li–S and Li–Se batteries. Rare Met 36:339–364. https://doi.org/10.1007/s12598-017-0891-z

Kang W, Deng N, Ju J et al (2016) A review of recent developments in rechargeable lithium–sulfur batteries. Nanoscale 8:16541–16588. https://doi.org/10.1039/C6NR04923K

Li C, Sui XL, Wang ZB et al (2017) 3D N-doped graphene nanomesh foam for long cycle life lithium-sulfur battery. Chem Eng J 326:265–272. https://doi.org/10.1016/j.cej.2017.05.154

Wang QQ, Huang JB, Li GR et al (2017) A facile and scalable method to prepare carbon nanotube-grafted-graphene for high performance Li-S battery. J Power Sources 339:20–26. https://doi.org/10.1016/j.jpowsour.2016.11.038

Wang M, Zhang H, Zhang Y et al (2013) A modified hierarchical porous carbon for lithium/sulfur batteries with improved capacity and cycling stability. J Solid State Electrochem 17:2243–2250. https://doi.org/10.1007/s10008-013-2096-1

Zheng M, Zhang S, Chen S et al (2017) Activated graphene with tailored pore structure parameters for long cycle-life lithium–sulfur batteries. Nano Res 10:4305–4317. https://doi.org/10.1007/s12274-017-1659-3

Zhang S, Zheng M, Lin Z et al (2014) Activated carbon with ultrahigh specific surface area synthesized from natural plant material for lithium-sulfur batteries. J Mater Chem A 2:15889–15896. https://doi.org/10.1039/c4ta03503h

Wang JG, Xie K, Wei B (2015) Advanced engineering of nanostructured carbons for lithium-sulfur batteries. Nano Energy 15:413–444. https://doi.org/10.1016/j.nanoen.2015.05.006

Liang J, Sun ZH, Li F, Cheng HM (2016) Carbon materials for Li-S batteries: functional evolution and performance improvement. Energy Storage Mater 2:76–106. https://doi.org/10.1016/j.ensm.2015.09.007

Zellmer S, Titscher P, Wienken E et al (2017) Fabrication of carbon-sulphur composites via a vibration mill process as cathode material for lithium sulphur batteries. Energy Storage Mater 9:70–77. https://doi.org/10.1016/j.ensm.2017.06.010

Yuan G, Yin F, Zhao Y et al (2016) Corn stalk-derived activated carbon with a stacking sheet-like structure as sulfur cathode supporter for lithium/sulfur batteries. Ionics (Kiel) 22:63–69. https://doi.org/10.1007/s11581-015-1528-6

Xue M, Chen C, Ren Z et al (2017) A novel mangosteen peels derived hierarchical porous carbon for lithium sulfur battery. Mater Lett 209:594–597. https://doi.org/10.1016/j.matlet.2017.08.090

Cheng Y, Ji S, Liu Y, Liu J (2015) High sulfur loading in activated bamboo-derived porous carbon as a superior cathode for rechargeable Li–S batteries. Arab J Chem. https://doi.org/10.1016/j.arabjc.2015.10.001

Gaddam RR, Yang D, Narayan R et al (2016) Biomass derived carbon nanoparticle as anodes for high performance sodium and lithium ion batteries. Nano Energy 26:346–352. https://doi.org/10.1016/j.nanoen.2016.05.047

Imtiaz S, Zhang J, Zafar ZA et al (2016) Biomass-derived nanostructured porous carbons for lithium-sulfur batteries. Sci China Mater 59:389–407. https://doi.org/10.1007/s40843-016-5047-8

Półrolniczak P, Nowicki P, Wasiński K et al (2016) Biomass-derived hierarchical carbon as sulfur cathode stabilizing agent for lithium-sulfur batteries. Solid State Ion 297:59–63. https://doi.org/10.1016/j.ssi.2016.10.012

Zhu Y, Xu G, Zhang X et al (2017) Hierarchical porous carbon derived from soybean hulls as a cathode matrix for lithium-sulfur batteries. J Alloys Compd 695:2246–2252. https://doi.org/10.1016/j.jallcom.2016.11.075

Li Z, Huang Y, Yuan L (2015) Status and prospects in sulfur–carbon composites as cathode materials for rechargeable lithium–sulfur batteries. Carbon N Y 92:41–63. https://doi.org/10.1016/j.carbon.2015.03.008

Yan Y, Shi M, Wei Y et al (2018) Process optimization for producing hierarchical porous bamboo-derived carbon materials with ultrahigh specific surface area for lithium-sulfur batteries. J Alloys Compd 738:16–24. https://doi.org/10.1016/j.jallcom.2017.11.212

Xue M, Lu W, Chen C et al (2019) Optimized synthesis of banana peel derived porous carbon and its application in lithium sulfur batteries. Mater Res Bull 112:269–280. https://doi.org/10.1016/j.materresbull.2018.12.035

Song Y, Wang H, Ma Q et al (2019) Dandelion derived nitrogen-doped hollow carbon host for encapsulating sulfur in lithium sulfur battery. ACS Sustain Chem Eng 7:3042–3051. https://doi.org/10.1021/acssuschemeng.8b04648

Acknowledgements

This study was supported by the TUBITAK 2221—Fellowships for Visiting Scientists and Scientists on Sabbatical Leave.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arie, A.A., Kristianto, H., Cengiz, E.C. et al. Preparation of salacca peel-based porous carbons by K2CO3 activation method as cathode materials for LiS battery. Carbon Lett. 30, 207–213 (2020). https://doi.org/10.1007/s42823-019-00085-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-019-00085-1