Abstract

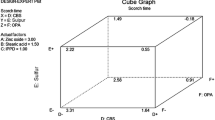

Various types of chemical ingredients are needed in the rubber compounding process to obtain desired properties for a commercially useful application. To content with this, Plackett–Burman design (PBD) provides an efficient way of dealing with a large number of variables and identifying the most important parameter. This study reviews the exploitation of PBD to screen the significant effect of different compounding ingredients as well as oil palm ash (OPA) to the tensile properties of acrylonitrile butadiene rubber (NBR). The two most significant components were chosen for each tensile property. Furthermore, three-dimensional plots and their respective contour plots were used to investigate the simultaneous interactions of different factors on the responses studied. Based on the result obtained, the tensile strength showed an increasing trend when N-cyclohexyl-2-benzothiazole sulfenamide (CBS) concentration increased; however, the increase in stearic acid has resulted in a decline in tensile strength. On the other hand, the sulphur crosslinker with the largest effect value has shown a significant reduction towards the elongation at break. For tensile modulus, sulphur and OPA which are the two most significant variables had contributed to a synergistic effect as the concentration increased.

Similar content being viewed by others

References

Wicke B, Sikkema R, Dornburg V, Faaij A (2011) Exploring land use changes and the role of palm oil production in Indonesia and Malaysia. Land Use Policy 28(1):193. https://doi.org/10.1016/j.landusepol.2010.06.001

Ooi ZX, Ismail H, Abu Bakar A (2013) Synergistic effect of oil palm ash filled natural rubber compound at low filler loading. Polym Test 32(1):38. https://doi.org/10.1016/j.polymertesting.2012.09.007

Teoh YP, Ooi ZX, Bakar AA, Ismail H (2016) Exploiting the Plackett–Burman design to examine the formulation effect on curing characteristics of oil palm ash-filled acrylonitrile butadiene rubber compounds. Iran Polym J 25(3):285. https://doi.org/10.1007/s13726-016-0422-z

Ooi ZX, Ismail H, Bakar AA (2015) Characterization of oil palm ash (OPA) and thermal properties of OPA-filled natural rubber compounds. J Elastom Plast 47(1):13. https://doi.org/10.1177/0095244313489901

Marini G, Luchese MD, Argondizzo APC, Andrade ACM, Galler R, Alves TLM, Medeiros MA, Latentis AL (2014) Experimental design approach in recombinant protein expression: determining medium composition and induction conditions for expression of pneumolysin from streptococcus pneumonia in escherichia coli and preliminary purification process. BioMed Central Biotechnol 14:1. https://doi.org/10.1186/1472-6750-14-1

Teoh YP, Mat Don M (2012) Optimization of parameters for mycelia growth by schizophyllum commune and a kinetic model study of its growth morphology. J Appl Sci 12(1):1100. https://doi.org/10.3923/jas.2012.1100.1105

Chukwu MN, Madufor IC, Ayo MD, Ekebafe LO (2011) Effect of stearic acid level on the physical properties of natural rubber vulcanisate. Pac J Sci Technol 12(1):344

Dunn JR (2011) Carboxylated rubber. In: Bhowmick AK, Stephens H (eds) Handbook of elastomers. Second edition, revised and expanded. Marcel Dekker Inc, New York, pp 561–590

Choi SS, Nah C, Jo BW (2003) Properties of natural rubber composites reinforced with silica or carbon black: influence of cure accelerator content and filler dispersion. Polym Int 52(8):1382. https://doi.org/10.1002/pi.1232

Markovic G, Radovanovic B, Marinovic-Cincovic M, Budinski-Simendic J (2009) The effect of accelerators on curing characteristics and properties of natural rubber/chlorosulphonated polyethylene rubber blend. Mater Manuf Process 24(10–11):1224. https://doi.org/10.1080/10426910902967087

Verdejo R, Lopez-Manchado MA, Valentini L, Kenny JM (2010) Carbon nanotube reinforced rubber composites. In: Thomas S, Stephen R (eds) Rubber nanocomposites: preparation, properties, and applications. Wiley, Singapore, pp 147–168

Brown RP, Soulagnet G (2001) Microhardness profiles on aged rubber compounds. Polym Test 20(3):295. https://doi.org/10.1016/S0142-9418(00)00035-0

Ooi ZX, Ismail H, Teoh YP (2015) Interaction between 3-aminopropyltrimethoxysilane and oil palm ash in styrene butadiene rubber compounds using response surface methodology. Polym Test 43:131. https://doi.org/10.1016/j.polymertesting.2015.03.003

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Teoh, Y.P., Ooi, Z.X., Sam, S.T. et al. Assessment of oil palm ash and compounding ingredients on tensile properties of acrylonitrile–butadiene rubber using statistical design. J Rubber Res 22, 69–75 (2019). https://doi.org/10.1007/s42464-019-00011-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-019-00011-0