Abstract

Magnesium (Mg)-based material systems offer great potential for healing bone fracture and defects, in terms of reduced stress shielding effect and non-toxicity, due to their biodegradability and biocompatibility. However, an issue with controlling degradation rate of Mg in an intraosseous (occurring within bone) environment has impeded their application in orthopaedics. As a solution to this problem, Mg can be combined with other corrosion-resistant and bioactive materials to form composite. Hydroxyapatite (HA) is an attractive bioceramic for implants due to its similar chemical composition to the apatite found in bone. Thus, incorporation of HA in Mg assists in enhancing multiple engineering properties that are critical for its widespread use in orthopaedic application. Tremendous improvement in the mechanical and degradation properties of HA-reinforced Mg composite, along with their impressive biocompatibility, has led to further interest in research, which has resulted in some clinical trials of Mg–HA-based composites, as well. This review article summarises researches, carried out till date on Mg–HA-based composite, with a special focus on significant role of HA in tuning the degradation and mechanical behaviour of Mg-based materials. The detailed summary on biocompatibility of Mg–HA-based composites has also been covered. A comprehensive understanding on biocompatibility and degradation behaviour of Mg–HA system is needed to assess the potential of these composites in orthopaedic application. However, such review is missing in available literatures. On the basis of current studies available on Mg–HA-based composites for orthopaedic application, guidelines for future application in clinical trials have also been framed and presented in this review article.

Source: http://Scopus.com

Similar content being viewed by others

References

Hill G et al (2010) Benefits and associated risks of using allograft, autograft and synthetic bone fusion material for patients and service providers—a systematic review. JBI Libr Syst Rev 8:1–13

Moussy F et al (2010) Biomaterials for the developing world. J. Biomed. Mater. Res. A 94:1001–1003

Stumpf CP et al (2013) Biomaterials in dental ceramics, topics in mining, metallurgy and materials engineering. Springer, Berlin, pp 9–13

Zheng YF, Gu XN, Witte F et al (2014) Biodegradable metals. Mater Sci Eng, R 77:1–34

Katti S, Lakshmi IR, Laurecin CT et al (2002) Toxicity biodegradation and elimination of polyanhydrides. Adv Drug Deliv Rev 54:933–961

Vert M, Maudtui J, Li S et al (1994) Biodegradation of PLA/PGA polymers: increasing complexity. Biomaterials 15:1209–1213

Cai X, Tong H, Hu J et al (2009) Preparation and characterization of homogeneous chitosan–polylactic acid/hydroxyapatite nanocomposite for bone tissue engineering and evaluation of its mechanical properties. Acta Biomater 5:2693–2703

EdiTanase C et al (2014) PLA/chitosan/keratin composites for biomedical applications. Mater Sci Eng, C 40:242–247

Park SY et al (2010) Electrospun silk fibroin scaffolds with macropores for bone regeneration: an in vitro and in vivo study. Tissue Eng Part A 16:1271–1279

Mieszawska AJ et al (2011) Clay enriched silk biomaterials for bone formation. Acta Biomater 7:3036–3041

Wang Y et al (2008) In vivo degradation of three-dimensional silk fibroin scaffolds. Biomaterials 9(3):415–428

Bhattacharjee P et al (2017) Silk scaffolds in bone tissue engineering An overview. Acta Biomater 63:1–17

Terasaka S, Iwasaki Y, Uchida T et al (2006) Fibrin glue and polyglycolic acid non woven fabric as a biocompatible dural substitute. Neurosurgery 58:134–139

Witte F, Hort N, Kainer KU et al (2008) Degradable biomaterials based on magnesium corrosion. Curr Opin Solid State Mater Sci 12:63–72

Sáenz A, Rivera-Muñoz EW, Castaño VM et al (1991) Ceramic biomaterials: an introductory overview. J Mater Educ 21:297–306

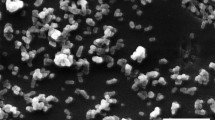

Khanra AK, Jung HC, Hong KS, Shin KS et al (2010) Microstructure and mechanical properties of Mg–HAP composites. Bull Mater Sci 33:43–47

Hee Kim Y, Jyoti MA, Youn M Ho, Sun Youn H, Seok Seo H et al (2010) In vitro and in vivo evaluation of a macro porous β-TCP granule-shaped bone substitute fabricated by the fibrous monolithic process. Biomed Mater 5:359–366

Gu YW, Loha NH, Tor SB, Cheang P et al (2002) Spark plasma sintering of hydroxyapatite powders. Biomaterials 23:37–43

White AA et al (2007) Hydroxyapatite–carbon nanotube composites for biomedical applications: a review. Int J Appl Ceram Technol 4:1–13

Yu LG, Khor KA, Cheang P et al (2003) Effect of spark plasma sintering on the microstructure and in vitro behavior of plasma sprayed HA coatings. Biomaterials 24:2695–2705

Hench LL et al (2002) Third-generation biomedical materials. Science 295:1014–1017

Xu W et al (2018) Accelerated corrosion of 316L stainless steel in simulated body fluids in the presence of H2O2 and albumin. Mater Sci Eng C 92:11–19

Sivakumar M, Dhanadurai KS, Thulasiraman V et al (1995) Failures in stainless steel orthopaedic implant devices: a survey. J Mater Sci Lett 14:351–354

Gonzalez-Carrasco JL et al (2009) Metals as bone repair materials. In: Planell JA, Best SM, Lacroix D, Merolli A (eds) Bone repair biomaterials. Woodhead Publishing, pp 154–193

Chen Q et al (2015) Metallic implant biomaterials. Mater Sci Eng R 87:1–57

Stohs SJ et al (1995) Oxidative mechanisms in the toxicity of metal ions. Free Radical Biol Med 18:321–336

Manam NS, Harun, Shri DNA et al (2017) Study of corrosion in biocompatible metals for implants: a review. J Alloys Compound 701:698–715

Jaiswal S, Manoj Kumara R, Roy P, Lahiri D et al (2018) Mechanical, corrosion and biocompatibility behaviour of Mg–3Zn–HA biodegradable composites for orthopaedic fixture accessories. J Mech Behav Biomed Mater 78:442–454

Rahim MI et al (2018) Advances and challenges of biodegradable implant materials with a focus on magnesium-alloys and bacterial infections. Metals 8:532

Pierson D et al (2012) A simplified in vivo approach for evaluating the bioabsorbable behaviour of candidate stent materials. J Biomed Mater Res B 100B:58–67

Staiger MP, Pietak AM, Dias G et al (2006) Magnesium and its alloys as orthopedic biomaterials: a review. Biomaterials 27:1728–1736

Waizy H, Reifenrath J, Windhagen H et al (2013) Biodegradable magnesium implants for orthopedic applications. J Mater Sci 48:39–50

Ratna Sunil B, Sampath Kumar TS, Nandakumar V et al (2014) Nano-hydroxyapatite reinforced AZ31 magnesium alloy by friction stir processing: a solid state processing for biodegradable metal matrix composites. J Mater Sci Mater Med 25:975–988

Ratna Sunil B, Sampath Kumar TS, Nandakumar V et al (2014) Friction stir processing of magnesium–nanohydroxyapatite composites with controlled in vitro degradation behavior. Mater Sci Eng C 39:315–324

Witte F, Fischer J, Crostack HA, Kaese, Beckmann F, Windhagen H et al (2006) In vitro and in vivo corrosion measurements of magnesium alloys. Biomaterials 27(7):1013–1018

Wang J, Xu W, Liu L Qin et al (2016) Biodegradable magnesium (Mg) implantation does not impose related metabolic disorders in rats with chronic renal failure. Sci Rep 6:26341

Lambotte L (1932) Utilisation of magnesium comme materiel perdu dans l’osteosynthèse. Bull Mem Soc Nat Chir 28:1325–1334

McBride ED (1938) Absorbable metal in bone surgery. J Am Med 111:2464–2467

Ratna Sunil B, Sampath Kumar TS et al (2014) Processing and mechanical behavior of lamellar structured degradable magnesium–hydroxyapatite implants. J Mech Behav Biomed Mater 40:178–189

Ahmadkhaniha D, Fedel M, Sohi A, Deflorian F et al (2016) Corrosion behavior of magnesium and magnesium–hydroxyapatite composite fabricated by friction stir processing in dulbecco’s phosphate buffered saline. Corros Sci 104:319–329

Wang X, Dong LH, Li XL, Ma XL, Zheng YF et al (2013) Microstructure, mechanical property and corrosion behavior of interpenetrating (HA+β-TCP)/MgCa composite fabricated by suction casting. Mater Sci Eng, C 33:4266–4273

Sawada K, Ika KF, Zasshi D et al (1998) 107(2):237–250

Kawatani H, Fukumoto K, Zairyo S et al (1994) 12(3):119–126

Khanra AK, Jung HC, Shin KS et al (2010) Comparative property study on extruded Mg–HAP and ZM61–HAP composites. Mater Sci Eng, A 527:6283–6288

Chen B, Yin KY, Lu TF, Sun BY, Zheng JX et al (2016) AZ91 magnesium alloy/porous hydroxyapatite composite for potential application in bone repair. J Mater Sci Technol 32:858–864

Haghshenas M et al (2017) Mechanical characteristics of biodegradable magnesium matrix composites: a review. J Magn Alloys 5(2):189–201

Gu X, Zhou W, Zheng Y, Xi Y, Chai D et al (2010) Microstructure, mechanical property, bio-corrosion and cytotoxicity evaluations of Mg/HA composites. Mater Sci Eng, C 30:827–832

Zhao J, Yu Z, Chen L et al (2011) Biodegradable behaviors of Mg–6%Zn–5% Hydroxyapatite biomaterial. Adv Mater Res 239–242:1287–1291

Sun J, Chen M, Cao G, Wei J et al (2013) The effect of nano-hydroxyapatite on the microstructure and properties of Mg–3Zn–0.5Zr alloy. J Compo Mater 48:825–834

Gu X, Zhou W, Zheng Y, Xi Y, Chai D et al (2010) Microstructure, mechanical property, bio-corrosion and cytotoxicity evaluations of Mg/HA composites. Mater Sci Eng C 30:827–832

Dubey A et al (2019) Mechanical integrity of biodegradable Mg–HA composite during in-vitro exposure. J Mater Eng Perform 8(2):800–809

Liu DB et al (2010) Fabrication and corrosion behavior of HA/Mg–Zn biocomposites. Front Mater Sci Chin 4:139–144

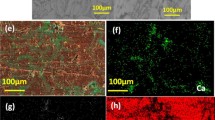

Dubey A, Jaiswal S, Roy P, Lahiri D et al (2019) Protein adsorption and biodegradation behaviour of Mg–3Zn/HA for biomedical application. Nanomater Energy 8:1–10

Salleh EM, Zuhailawati H, Noor M, Othman NK et al (2018) In vitro biodegradation and mechanical properties of Mg–Zn alloy and Mg–Zn–Hydroxyapatite composite produced by mechanical alloying for potential application in bone repair. Metall Mater Trans A 49:5888–5903

Guo P, Cui Z, Cheng L, WenxianWang W, Xu B et al (2016) Preparation of Mg/Nano-HA composites by spark plasma sintering method and evaluation of different milling time effects on their microhardness, corrosion resistance, and biocompatibility. Adv Eng Materals 19(1):1600294

Kim KR, Ahn JW, Han JH, Roh JS, Kim WJ, Kim HS et al (2014) Corrosion behavior of magnesium powder fabricated by high-energy ball milling and spark plasma sintering. Metall Mater Int 20(6):1095–1101

Azrina WN, Muhammada W, Mutohd Y, YukioMiyashitad Y et al (2011) Microstructure and mechanical properties of magnesium composites prepared by spark plasma sintering technology. J Alloy Compd 509:6021–6029

Viswanathan R, Rameshbabu N, Sreekanth D, Venkateswarlu K, Rani S, Muthupandi V et al (2013) Plasma electrolytic oxidation and characterization of spark plasma sintered magnesium/hydroxyapatite composites). Mater Sci Forum 765:827–831

Prakash C, Singh S, Mia M, Królczyk G, Khanna N et al (2018) Synthesis, characterization, corrosion resistance and in-vitro bioactivity behavior of biodegradable Mg–Zn–Mn–(Si–HA) composite for orthopaedic applications. Materials 111602

Prakash C, Sidhu S, Verma K, Sigh S et al (2018) Synthesis and characterization of Mg–Zn–Mn–HA composite by spark plasma sintering process for orthopedic applications. Vacuum 155:578–584

Campoa RD, Savoini B, Mongea MA, Garce´s G et al (2014) Mechanical properties and corrosion behavior of Mg–HAP composites. J Mech Behav Biomed Mater 39:238–246

Brown A, Zaky S, Sfeir C et al (2015) Porous magnesium/PLGA composite scaffolds for enhanced bone regeneration following tooth extraction. Acta Biomater 11:543–553

Liu Y, Liu D et al (2014) Corrosion properties of compositematerials HA (beta-TCP)/Mg–Zn–Ca. Rare Metal Mater Eng 43(1):205–209

Bansal S, Chauhan V, Juyal A, Raghuvanshi S et al (2009) Evaluation of hydroxyapatite and beta-tricalcium phosphate mixed with bone marrow aspirate as a bone graft substitute for posterolateral spinal fusion. Indian J Orthopaed 43:234–239

Ye X, Chen M et al (2010) In vitro corrosion resistance and cytocompatibility of nano-hydroxyapatite reinforced Mg–Zn–Zr composites. J Mater Sci Mater Med 21:1321–1328

Sun M, Chen G, Liu B, Wei J et al (2013) The effect of nano-hydroxyapatite on the microstructure and properties of Mg–3Zn–0.5Zr alloy. J Compos Mater 48:825–834

Champion E et al (2013) Sintering of calcium phosphate bioceramics. Acta Biomater 9:5855–5875

Kutty MG, Bhaduri SB, Yaghoubi A et al (2015) In situ measurement of shrinkage and temperature profile in microwave-and conventionally-sintered hydroxyapatite bioceramic. Mater Lett 161:375–378

Xiong G, Nie Y, Li J, Zhu Y, Li W et al (2016) Characterization of biomedical hydroxyapatite/magnesium composites prepared by powder metallurgy assisted with microwave sintering. Curr Appl Phys 16:830–836

Ma C, Chen L, Xu J, Frank E, Neil P, Duffie A, Zheng J, Li X et al (2013) Biodegradability and mechanical performance of hydroxyapatite reinforced magnesium matrix nanocomposites. Suppl Proc Vol 1 Mater Process Interfaces 120124

Ma C, Chen L, Xu J, Fehrenbacher A, Zheng J, Li X et al (2013) Effect of fabrication and processing technology on the biodegradability of magnesium nanocomposites. J Biomed Mater Res B Appl Biomater 101B

Li K, Zhao Y et al (2019) Research status and prospect of friction stir processing technology. Coatings 9:2–14

Khalil A, Sherif ME et al (2011) Corrosion passivation in simulated body fluid of magnesium/hydroxyapatite nanocomposites sintered by high frequency induction heating. Int J Electrochem Sci 6:6184–6199

Khalil A, Sherif ME et al (2012) Effect of high-frequency induction heat sintering conditions on the microstructure and mechanical properties of nanostructured magnesium/hydroxyapatite nanocomposites. Mater Des 36:58–68

Xu L, Pan F, Yang L, Zhang E, Yang K et al (2009) In vitro and in vivo evaluation of the surface bioactivity of a calcium phosphate coated magnesium alloy. Biomaterials 30:1512–1523

Chen B, Yin KY, Dong Q, Zheng JX, Lu C, Li ZC et al (2016) AZ91 magnesium alloy/porous hydroxyapatite composite for potential application in bone repair. J Mater Sci Technol 32:858–864

Kowalski K, Nowak M, Jurczyk M et al (2016) The effects of hydroxyapatite addition on the properties of the mechanically alloyed and sintered Mg–RE–Zr Alloy. 25:4469–4477

Pramanik S, Agarwal AK et al (2005) Development of high strength hydroxyapatite for hard tissue replacement. Trends Biomater Artif Organs 19:46–51

Saravanan RA, Surappa MK et al (2000) Fabrication and characterization of pure magnesium-30 vol% SiC particle composite. Mater Sci Eng A 276:108–116

Witte F, Kaese V, Switzer E, Lindenberg A, Wirth M, Windhagen H et al (2005) In vivo corrosion of magnesium alloys and the associated bone response. Biomaterials 26(17):3557–3563

Song G et al (2007) Control of biodegradation of biocompatible magnesium alloys. Corros Sci 49:1696–1701

Witte F, Feyerabend F, Fischer J, Blawert C, Dietzel W, Hort N et al (2007) Biodegradable magnesium–hydroxyapatite metal matrix composites. Biomaterials 28:2163–2174

Ye X, Chen M, Liu D et al (2010) In vitro corrosion resistance and cytocompatibility of nano-hydroxyapatite reinforced Mg–Zn–Zr composites. Journal of. Mater Sci Mater Med 21:1321–1328

Chiu C, Lu C, Ou KL et al (2017) Effect of hydroxyapatite on the mechanical properties and corrosion behavior of Mg–Zn–Y Alloy. Materials 10:855

Khalajabadia SZ, Abdul Kadira MR, Bakhsheshi HR, Farahany S et al (2014) Effect of mechanical alloying on the phase evolution, microstructure and bio-corrosion properties of a Mg/HA/TiO2/MgO nanocomposite. Ceram Int 40:16743–16759

Lia JX, Zhanga Y, Xie JX et al (2018) Effect of trace HA on microstructure, mechanical properties and corrosion behavior of Mg–2Zn–0.5Sr alloy. J Mater Sci Technol 34:299–310

Aboudzadeh N, Ali SM et al (2018) In vitro degradation and cytotoxicity of Mg − 5Zn − 0.3Ca/nHA biocomposites prepared by powder metallurgy. Trans Nonferrous Metall Soc China 28:1745–1754

Gill P et al (2012) Characterization and degradation behaviour of anodized magnesium-hydroxyapatite metal matrix composites. J Biomimetics Biomater Tissue Eng 16:55–69

Ma C, Chen L, Zheng J et al (2013) Effect of fabrication and processing technology on the biodegradability of magnesium nanocomposites. J Biomed Mater Res Part B 101:870–877

Nakka K, Chikkala N, Buradagunta S et al (2018) Developing composites of ZE41 Mg alloy-naturally derived hydroxyapatite by friction stir processing: investigating in vitro degradation behavior. Mater Technol 33:603–611

Ramya M, Pillai MM, Raj B, Ravi KR et al (2018) Hydroxyapatite particle (HAp) reinforced biodegradable Mg–Zn–Ca metallic glass composite for bio-implant applications. Biomed Phys Eng Express 4:25–39

Bohner M, Lemaitre J et al (2009) Can bioactivity be tested in vitro with SBF solution? Biomaterials 30:2175–2179

Zhao J, Yu MZ, Chen LJ et al (2011) Biodegradable behaviors of Mg–6%Zn–5% hydroxyapatite biomaterial. Adv Mater Res 239–242:1287–1291

Collier T, Jenney CR, Anderson JM et al (1997) Protein adsorption on chemically modified surfaces. Biomed Sci Instrum 33:178–183

Seal CK, Vince K, Hodgson MA et al (2009) Biodegradable surgical implants based on magnesium alloys- a review of current research. IOP Conf Ser Mater Sci Eng 4:06–011

Oliva J, Cama J, Cortina JL, Ayora C, De Pablo J et al (2012) Biogenic hydroxyapatite (Apatite II™) dissolution kinetics and metal removal from acid mine drainage. J Hazard Mater 213:7–18

Acknowledgements

The authors are thankful to Ms. Swati Haldar from Centre of Nanotechnology of Indian Institute of Technology Roorkee, for her help and support in understanding of biological studies. D.L. acknowledges funding from the Department of Science and Technology, India (SB/SO/HS/138/2013). The figures from other articles have been reproduced in this review with permission from the respective publishers and the appropriate citation is mentioned using reference numbers in figure captions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jaiswal, S., Dubey, A. & Lahiri, D. In Vitro Biodegradation and Biocompatibility of Mg–HA-Based Composites for Orthopaedic Applications: A Review. J Indian Inst Sci 99, 303–327 (2019). https://doi.org/10.1007/s41745-019-00124-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41745-019-00124-w