Abstract

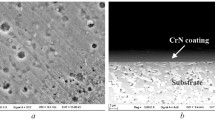

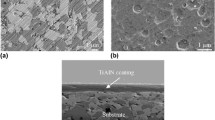

A CrC coating was deposited on YT14 cutting tools using a cathodic arc ion plating. The surface and cross-section morphologies, chemical elements and phases of obtained CrC coating were analyzed using a field emission scanning electron microscope, energy disperse spectrometer, and X-ray diffractometer. The tribological properties of CrC coating under the dry, water and oil lubrication conditions were investigated using a wear test, the effects of lubrication conditions on the friction coefficient and wear properties of CrC coatings were also discussed. The results show that, the average friction coefficient of CrC coating under the dry, water, and oil lubrication conditions are 0.76, 0.11, and 0.35, respectively, the wear mechanism is abrasive wear. The average residual stresses of worn tracks under the dry, water, and oil lubrication conditions are −231.1 ± 25.0, −210.4 ± 23.0, and −205.9 ± 2.0 MPa, respectively, of which the stress value under the oil lubrication condition is the smallest, showing its reduction wear property.

Similar content being viewed by others

References

Klünsner, T., Zielbauer, F., Marsoner, S., Deller, M., Morstein, M., and Mitterer, C., Influence of surface topography on early stages on steel galling of coated WC-Co hard metals, Int. J. Refract. Met. H., 2016, vol. 57, pp. 24–30.

Katiyar, P.K., Singh, P.K., Singh, R., and Lava Kumar, A., Modes of failure of cemented tungsten carbide tool bits (WC/Co): A study of wear parts, Int. J. Refract. Met. H., 2016, vol. 54, pp. 27–38.

Tarragó, J.M., Dorvlo, S., Esteve, J., and Llanes, L., Influence of the microstructure on the thermal shock behavior of cemented carbides, Ceram. Int., 2016, vol. 42, pp. 12701–12708.

Ghaziof, S., Golozar, M.A., and Raeissi, K., Characterization of as-deposited and annealed Cr-C alloy coatings produced from a trivalent chromium bath, J. Alloys Compd., 2010, vol. 496, no. 1–2, pp. 164–168.

Zeng, Z.X., Wang, L.P., Liang, A.M., and Zhang, J.Y., Tribological and electrochemical behavior of thick Cr-C alloy coatings electrodeposited in trivalent chromium bath as an alternative to conventional Cr coatings, Electrochim. Acta, 2006, vol. 52, no. 3, pp. 1366–1373.

Gao, S.J., Dong, C.F., Luo, H., Xiao, K., Pan X.M., and Li, X.G., Scanning electrochemical microscopy study on the electrochemical behavior of CrN film formed on 304 stainless steel by magnetron sputtering, Electrochim. Acta, 2013, vol. 114, pp. 233–241.

Tsai, Y.Z. and Duh, J.G., Tribological behavior of CrN/WN multilayer coatings grown by ion-beam assisted deposition, Surf. Coat. Technol., 2006, vol. 201, no. 7, pp. 4266–4272.

Rodriguez, R.J., Garcia, J.A., Medrano, A., Rico, M., Sánchez, R., Martinez, R., Labrugère, C., Lahaye, M., and Guette, A., Tribological behavior of hard coatings deposited by arc-evaporation PVD, Vacuum, 2002, vol. 67, no. 3, pp. 559–566.

Wan, X.S., Shi, Y.Y., Ma, J., Li, H.Q., Gong, J., and Sun C., Salt spray corrosion behaviour of CrN coatings deposited by arc ion plating, Acta Metall. Sin., 2010, vol. 43, no. 5, pp. 600–606.

Henderer, W. and Xu, F., Hybrid TiSiN, CrC/C PVD coatings applied to cutting tools, Surf. Coat. Technol., 2013, vol. 215, pp. 381–385.

Chen, X.H., Zhang, P.Z., Wei, D.B., Ding, F., Li, F.K., Wei, X.F., and Ma, S.J., Preparation and characterization of Cr/CrC multilayer on γ-TiAl alloy by the double glow plasma surface alloying technology, Mater. Lett., 2017, vol. 386–387, pp. 80–89.

Keunecke, M., Bewilogua, K., Becker, J., Gies, A., and Grischke, M., CrC/a-C: H coatings for highly loaded, low friction applications under formulated oil lubrication, Surf. Coat. Technol., 2012, vol. 207, pp. 270–278.

Tillmann, W., Dias, N.F.L., and Stangier, D., Tribo-mechanical properties of CrC/a-C thin films sequentially deposited by HiPIMS and mfMS, Surf. Coat. Technol., 2018, vol. 335, pp. 173–180.

Eriksson, J. and Olsson, M., Tribological testing of commercial CrN, (Ti, Al)N and CrC/C PVD coatings—Evaluation of galling and wear characteristics against different high strength steels, Surf. Coat. Technol., 2011, vol. 205, no. 16, pp. 4045–4051.

Rodriguez, R.J., Garcia, J.A., Medrano, A., Rico, M., Sánchez, R., Martinez, R., Labrugère, C., Lahaye, M., and Guette, A., Tribological behaviour of hard coatings deposited by arc-evaporation PVD, Vacuum, 2002, vol. 67, no. 3, pp. 559–566.

Hirota, K., Mitani, K., Yoshinaka, M., and Yamaguchi, O., Simultaneous synthesis and consolidation of chromium carbides (Cr3C2, Cr7C3 and Cr23C6) by pulsed electric-current pressure sintering, Mater. Sci. Eng. A, 2009, vol. 399, no. 1–2, pp. 154–160.

Korkmaz, K., Investigation and characterization of electrospark deposited chromium carbide-based coating on the steel, Surf. Coat. Technol., 2015, vol. 272, no. 25, pp. 1–7.

Sen, S., Influence of chromium carbide coating on tribological performance of steel, Mater. Design, 2006, vol. 27, no. 2, pp. 85–91.

Stallard, J., Mercs, D., Jarratt, M., Teer, D.G., and Shipway P.H., A study of the tribological behaviour of three carbon-based coatings, tested in air, water and oil environments at high loads, Surf. Coat. Technol., 2004, vol. 177, no. 3, pp. 545–551.

Wang, D.Y., Weng, K.W., Chang, C.L., and Ho, W.Y., Synthesis of Cr3C2 coatings for tribological applications, Surf. Coat. Technol., 1999, vols. 120–121, pp. 622–628.

Funding

Financial support for this research by the Jiangsu Province Science and Technology Support Program (Industry) (BE2014818) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

The text was submitted by the authors in English.

About this article

Cite this article

Zhao, W., Zhu, S. & Kong, D. Friction-Wear Characterization of Cathodic Arc Ion Plated CrC Coating under Different Lubrication Conditions. J. Superhard Mater. 41, 402–411 (2019). https://doi.org/10.3103/S1063457619060042

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063457619060042