Abstract

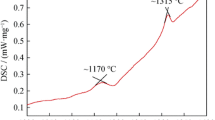

Ti44Al6Nb-based alloy ingots with different cerium (Ce) contents (0, 0.05, 0.10, 0.15, 0.20; at%) were prepared by non-consumable vacuum arc smelting furnace (WK-II). The surface quality, macrostructure, microstructure, compressive properties and fracture morphology of these ingots were studied. The results show that Ce has few influences on the surface quality. Ce can refine grain size and the average grain size decreases from 0.50 to 0.19 mm with the increase of Ce content. Meanwhile, the microstructure morphology of these ingots changes from large lamellar microstructure to dual-phase microstructure. With addition of Ce, CeO and AlCe3 are formed during melting and solidifying, which act as the core of heterogeneous nucleation and refine the grain. The compressive testing results show that Ce can improve strength and ductility. The ultimate compressive strength increases from 1156.2 to 1472.2 MPa with Ce content increasing from 0 at% to 0.20 at%. The compression ratio is improved from 10.2 % to 15.3 % with Ce content increasing from 0 at% to 0.10 at%. The refined crystalline strengthening and grain boundary strengthening are the main reasons for the improvement of compressive property.

Similar content being viewed by others

References

Lv J, Liu BC. High strength cast aluminum alloy. Casting. 2000;49(2):66.

Li YY, Guo GW, Luo ZQ, Long Y. Development of high strength-toughness cast aluminum alloy. Spec Cast Nonferrous Alloys. 2000;6:45.

Song RG. Research status and development trend of high strength aluminum alloy. Mater J. 2000;14(1):20.

Kothari K, Radhakrishnan R, Wereley NM. Advances in gamma titanium aluminides and their manufacturing techniques. Prog Aerosp Sci. 2012;55:1.

Gil I, Muñoz-Morris MA, Morris DG. The effect of heat treatments on the microstructural stability of the intermetallic Ti–46.5Al–2W-0.5Si. Intermetallics. 2001;9(5):373.

Lapin J, Klimová A. Effect of heat treatment on the microstructure and hardness of a cast intermetallic Ti-46Al-2W-0.5Si alloy. Kovove Mater. 2003;41(1):1.

Appel F, Wagner R. Microstructure and deformation of two-phase γ-titanium aluminides. Mater Sci Eng, R. 1998;22(5):187.

Kitkamthorn U, Zhang LC, Aindow M. The structure of ribbon borides in a Ti-44Al-4Nb-4Zr-1B alloy. Intermetallics. 2006;14(7):759.

Huang L, Lian PK, Liu CT, Liu Y, Huang JS. Microstructural evolution of (TiAl) + Nb + W+B alloy. Transform Nonferrous Metals Soc China. 2011;21(10):2192.

Wu Y, Khwang S. Microstructural refinement and improvement of mechanical properties and oxidation resistance in EPM TiAl based intermetallics with yttrium addition. Acta Mater. 2002;50(6):1479.

Shen Q, Wang HY, Chen KM, Yuan XM, Jin J. Effects of nano-cerium oxide on microstructure and hardness of MCrAlY cladded coating on TC11 alloy. Chin J Rare Met. 2014;38(1):35.

Hong Y, Wu YC, Li Y, Wang FT, Wang QP, Li DH. Effect of rare earth La and Ce on microstructure and properties of TiAl alloy prepared by mechanical alloying. J Aeronaut Mater. 2009;29(4):17.

Liu XP, Cuevas F, Jiang LJ, Latroche M, Li ZN, Wang SM. Improvement of the hydrogen storage properties of Ti-Cr-V-Fe BCC alloy by Ce addition. J Alloy Compd. 2009;476(1–2):403.

Li HY, Sun Y, Bin J, Liu Y, Cao J. Effect of cerium on as-cast microstructure and properties of heat-resistant aluminum conductor. J Central South Univ. 2011;42(10):3026.

Jiang SY, Li SC. Valence electron structures and properties of Al–Ce compounds. Rare Metal Mater Eng. 2013;42(2):397.

Liu RZ, Wang KS, Feng PF, An G, Yang QL, Zhao H. Microstructure and tensile properties of Mo alloy synthetically strengthened by nano-Y2O3 and nano-CeO2. Rare Met. 2014;33(1):58.

Sun WC, Zhang SR, Hou AQ. Behaviors of RE Elements in Aluminum Alloys. Beijing: Weapon Industry Press; 1992. 231.

Fu GS, Sun FS, Ren LY, Chen WZ, Qian KW. Modification behavior of trace rare earth on impurity phases in commercial pure aluminum. J Chin Rare Earth Soc. 2001;19(2):133.

Hume-Rothery W, Raynor GV. Structure of Metals and Alloys. London: Institute of Metals Press; 1962. 225.

Zhang DE, Lu JD, Zhang XY. Study on the effect of rare earth Ce in a new casting aluminum alloy. J Hunan Uni Sci Technol. 2009;24(3):41.

Wang LM. Effect of rare earth elements (REE) on the structure and properties of certain aluminum alloy. Light Alloy Fabr Technol. 1994;22(9):37.

Peng RS, Liu J, Liu ZY, Dong BJ. Research on the function of ZA-27 alloys with rare earth modification. Acta Rare-Earth Sinica China. 1993;11(2):148.

Chen YG, Guo DH. Effect of rare earth elements in Zn-Al cast alloys. REE. 1994;15(5):42.

Wang TB, Qi XQ, Wang XD, Liu ChY. Effect of rare earth on the cast constitution in 3X04 aluminum alloy. Chin J Rare Met. 2008;32(4):426.

Qi WJ, Wang SC, Chen XM, Nong D, Zhou Z. Effective nucleation phase and grain refinement mechanism of Al-5Ti-1B master alloy. Chin J Rare Met. 2013;37(2):179.

Lin YZ, Fu GS, Cao R, Chen JH, Hu DW. Compression damage and fracture behaviors of γ-TiAl based alloys. Chin J Rare Met. 2014;38(2):334.

Ma ZK. Effect of B and La and Ce on structure and mechanical properties of Ti44Al6Nb alloys. Harbin: Harbin Institute of Technology; 2011. 1.

Acknowledgments

This research was financially supported by the National Natural Science of Foundation of China (No. 51274076), the Program of New Century Excellent Talents in University (No. NCET-12-0153), and the National Basic Research Program of China (No. 2011CB605504).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fang, HZ., Chen, RR., Chen, XY. et al. Microstructure and mechanical properties of Ti44Al6Nb alloys with different cerium contents. Rare Met. 39, 402–407 (2020). https://doi.org/10.1007/s12598-015-0611-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0611-5