Abstract

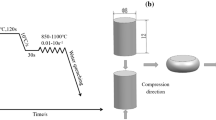

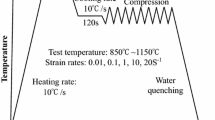

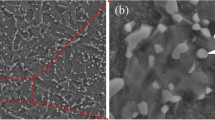

Isothermal compression tests of as-forged 30Si2MnCrMoVE low-alloying ultra-high-strength steel were carried out on a Gleeble 3500 thermal simulator at the deformation temperatures of 950–1150 °C and strain rates of 0.01–10 s−1. Based on the classical stress–dislocation density relationship and the kinematics of the dynamic recrystallization, the constitutive equations of the work hardening dynamical recovery period and dynamical recrystallization period were developed by using the work hardening curve and Avrami equation, which shows good agreement with the experimental value. Processing maps at the strain of 0.90 were constructed based on dynamic material model and were analyzed combined with microstructure observation under different conditions. The optimum parameter based on the processing maps was obtained and verified by a supplementary experiment. The power dissipation maps and instability maps at strains of 0.05–0.90 were also constructed, and the evolution law was analyzed in detail. The established constitutive equation and hot processing maps can provide some guidance for hot working process.

Similar content being viewed by others

References

B. Gong, X.W. Duan, J.S. Liu, J.J. Liu, Vacuum 155 (2018) 345–357.

A. Momeni, K. Dehghani, Mater. Sci. Eng. A 527 (2010) 5467–5473.

K.A. Babu, S. Mandal, C.N. Athreya, B. Shakthipriya, V.S. Sarma, Mater. Des. 115 (2017) 262–275.

A. Mohamadizadeh, A. Zarei-Hanzaki, H.R. Abedi, S. Mehtonen, D. Porter, Mater. Charact. 107 (2015) 293–301.

Y.V.R.K. Prasad, T. Seshacharyulu, Int. Mater. Rev. 43 (1998) 243–258.

Y.C. Lin, M.S. Chen, J. Zhong, Mech. Res. Commun. 35 (2008) 142–150.

C. Zhang, L. Zhang, W. Shen, C. Liu, Y. Xia, R. Li, Mater. Des. 90 (2016) 804–814.

Z. Yang, F. Zhang, C. Zheng, M. Zhang, B. Lv, L. Qu, Mater. Des. 66 (2015) 258–266.

S.H. Cho, Y.C. Yoo, J. Mater. Sci. 36 (2001) 4267–4272.

X. Ma, Z. An, L. Chen, T. Mao, J. Wang, H. Long, H. Xue, Mater. Des. 86 (2015) 848–854.

R. Raj, Metall. Trans. A 12 (1981) 1089–1097.

Y.V.R.K. Prasad, J. Mater. Eng. Perform. 12 (2013) 2867–2874.

Y.V.R.K. Prasad, Metall. Mater. Trans. A 27 (1996) 235–236.

B. Guo, H. Ji, X. Liu, L. Gao, R. Dong, M. Jin, Q. Zhang, J. Mater. Eng. Perform. 21 (2012) 1455–1461.

C. Zener, J.H. Hollomon, J. Appl. Phys. 15 (1944) 22–32.

H. Mirzadeh, J.M. Cabrera, A. Najafizadeh, Acta Mater. 59 (2011) 6441–6448.

Y. Estrin, H. Mecking, Acta Metall. 32 (1984) 57–70.

C.M. Sellars, W.J. McTegart, Acta Metall. 14 (1966) 1136–1138.

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, D.R. Barker, Metall. Trans. A 15 (1984) 1883–1892.

S.V.S.N. Murty, B.N. Rao, J. Mater. Sci. Lett. 14 (1998) 1203–1205.

J. Luo, L. Li, M.Q. Li, Mater. Sci. Eng. A 606 (2014) 165–174.

J. Luo, M.Q. Li, B. Wu, Mater. Sci. Eng. A 530 (2011) 559–564.

E. Pu, W. Zheng, J. Xiang, Z. Song, J. Li, Mater. Sci. Eng. A 598 (2014) 174–182.

G. Quan, L. Zhao, T. Chen, Y. Wang, Y. Mao, W. Lv, J. Zhou, Mater. Sci. Eng. A 538 (2012) 364–373.

Y. Wang, Q. Pan, Y. Song, C. Li, Z. Li, Mater. Des. 51 (2013) 154–160.

Acknowledgements

This work was supported by the Shaanxi Key Research and Development Program (No. S2017-ZDYF-ZDXM-GY-0115), Natural Science Basic Research Plan in Shaanxi Province of China (No. 2017JM5010) and Fundamental Research Funds for the Central Universities of China (No. 3102019ZX004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Liu, D., Wang, Jg. et al. Characterization of hot deformation behavior of 30Si2MnCrMoVE low-alloying ultra-high-strength steel by constitutive equations and processing maps. J. Iron Steel Res. Int. 27, 807–819 (2020). https://doi.org/10.1007/s42243-019-00335-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-019-00335-6