Abstract

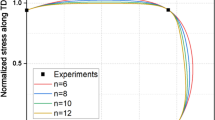

In this study, an anisotropic constitutive model based on the non-associated flow rule was developed for anisotropic sheet metals. This model was defined in the quadratic form of the Hill’s anisotropic function under a general three-dimensional stress condition. The anisotropic parameters for the yield function were identified using the directional planar yield stresses, bulge yield stress and shear yield stress, while those for the plastic potential function were identified using the directional r-values. A full expression related to the non-associated flow rule was applied and the model was implemented into the finite element code ABAQUS. A static-implicit analysis and the solid element were applied. Capability of the developed model for predicting the anisotropic behavior of sheet metal was investigated by considering two different sheet metal forming processes: cylindrical cup drawing of AA2090-T3, A6061P-T6 and SPCE; and hole expansion forming test of A6016-O. Cup heights and through-thickness strain distributions obtained from the simulations were compared with the experimental data. Results demonstrate that the developed material model considering 3D condition can improve accuracy of predicting the anisotropic behaviors. Furthermore, the simple formulations are efficient and user-friendly for computational analyses and solving the common industrial sheet metal forming problems.

Similar content being viewed by others

Abbreviations

- \(\varvec{d\sigma }\) :

-

Stress tensor increment

- \(\varvec{d\varepsilon }\) :

-

Strain tensor increment

- \(\varvec{d\varepsilon }^{{e}}\) :

-

Elastic strain increment

- \(\varvec{d\varepsilon }^{{p}}\) :

-

Plastic strain increment

- \(d\overline{\varepsilon }^{p}\) :

-

Equivalent plastic strain increment

- \(d\lambda\) :

-

Plastic multiplier increment

- \(dW\) :

-

Plastic work increment

- \(\varvec{D}^{e}\) :

-

Elastic stiffness tensor

- \(\varvec{D}^{ep}\) :

-

Elastic–plastic tangent modulus

- \(\phi\) :

-

Yield criterion

- \(\bar{\varepsilon }^{p}\) :

-

Equivalent plastic strain

- \(f\) :

-

Yield stress function

- \(g\) :

-

Plastic potential function

- \(h\) :

-

Isotropic hardening function

- \(F,G,H,L,M,N\) :

-

Parameters of the yield function

- \(F^{*} ,G^{*} ,H^{*} ,L^{*} ,M^{*} ,N^{*}\) :

-

Parameters of the potential function

- \(\varvec{m}\) :

-

First order gradient of the yield function

- \(\varvec{n}\) :

-

First order gradient of the potential function

- \(P\) :

-

Ratio of the potential function to the yield function

- \(\bar{\sigma }_{f}\) :

-

Equivalent stress of the yield function

- \(\bar{\sigma }_{g}\) :

-

Equivalent stress of the potential function

- \(\sigma_{Y}\) :

-

Equivalent stress at uniaxial tension

- \(\varvec{\sigma}\) :

-

Cauchy stress tensor

- \(\varvec{\sigma}^{{{tri}}}\) :

-

Trial stress tensor

- \(\varvec{\sigma}^{{c}}\) :

-

Stress tensor after plastic correction

- \(\varvec{X }:\varvec{Y}\) :

-

Double contraction of tensors X and Y

- \(\varvec{X} \otimes \varvec{Y}\) :

-

Tensor product of tensors X and Y

References

Park, H. S., Nguyen, T. T., & Dang, X. P. (2016). Energy-efficient optimization of forging process considering the manufacturing history. International Journal of Precision Engineering and Manufacturing Green Technology,3, 147–154.

Jang, D. Y., Jung, J., & Seok, J. (2016). Modeling and parameter optimization for cutting energy reduction in MQL milling process. International Journal of Precision Engineering and Manufacturing Green Technology,3, 5–12.

Hill, R. (1948). A theory of the yielding and plastic flow of anisotropic metals. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences,193, 281–297.

Pearce, R. (1968). Some aspects of anisotropic plasticity in sheet metals. International Journal of Mechanical Sciences,10, 995–1004.

Hill, R. (1979). Theoretical plasticity of textured aggregates. Mathematical Proceedings of the Cambridge Philosophical Society,85, 179–191.

Hill, R. (1990). Constitutive modelling of orthotropic plasticity in sheet metals. Journal of the Mechanics and Physics of Solids,38, 405–417.

Banabic, D., Kuwabara, T., Balan, T., Comsa, D. S., & Julean, D. (2003). Non-quadratic yield criterion for orthotropic sheet metals under plane-stress conditions. International Journal of Mechanical Sciences,45, 797–811.

Banabic, D., Aretz, H., Comsa, D. S., & Paraianu, L. (2005). An improved analytical description of orthotropy in metallic sheets. International Journal of Plasticity,21, 493–512.

Barlat, F., Lege, D. J., & Brem, J. C. (1991). A six-component yield function for anisotropic materials. International Journal of Plasticity,7, 693–712.

Barlat, F., et al. (1997). Yielding description for solution strengthened aluminum alloys. International Journal of Plasticity,13, 385–401.

Barlat, F., et al. (2003). Plane stress yield function for aluminum alloy sheets—part 1: Theory. International Journal of Plasticity,19, 1297–1319.

Barlat, F., et al. (2005). Linear transfomation-based anisotropic yield functions. International Journal of Plasticity,21, 1009–1039.

Barlat, F., Yoon, J. W., & Cazacu, O. (2007). On linear transformations of stress tensors for the description of plastic anisotropy. International Journal of Plasticity,23, 876–896.

Hu, W. (2005). An orthotropic yield criterion in a 3-D general stress state. International Journal of Plasticity,21, 1771–1796.

Hu, W. (2007). Constitutive modeling of orthotropic sheet metals by presenting hardening-induced anisotropy. International Journal of Plasticity,23, 620–639.

Spitzig, W. A., & Richmond, O. (1984). The effect of pressure on the flow stress of metals. Acta Metallurgica,32, 457–463.

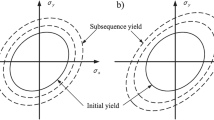

Stoughton, T. B. (2002). A non-associated flow rule for sheet metal forming. International Journal of Plasticity,18, 687–714.

Cvitanić, V., Vlak, F., & Lozina, Ž. (2008). A finite element formulation based on non-associated plasticity for sheet metal forming. International Journal of Plasticity,24, 646–687.

Stoughton, T. B., & Yoon, J. W. (2004). A pressure-sensitive yield criterion under a non-associated flow rule for sheet metal forming. International Journal of Plasticity,20, 705–731.

Stoughton, T. B., & Yoon, J. W. (2006). Review of Drucker’s postulate and the issue of plastic stability in metal forming. International Journal of Plasticity,22, 391–433.

Stoughton, T. B., & Yoon, J. W. (2008). On the existence of indeterminate solutions to the equations of motion under non-associated flow. International Journal of Plasticity,24, 583–613.

Taherizadeh, A., Green, D. E., Ghaei, A., & Yoon, J.-W. (2010). A non-associated constitutive model with mixed iso-kinematic hardening for finite element simulation of sheet metal forming. International Journal of Plasticity,26, 288–309.

Taherizadeh, A., Green, D. E., & Yoon, J. W. (2011). Evaluation of advanced anisotropic models with mixed hardening for general associated and non-associated flow metal plasticity. International Journal of Plasticity,27, 1781–1802.

Taherizadeh, A., Green, D. E., & Yoon, J. W. (2015). A non-associated plasticity model with anisotropic and nonlinear kinematic hardening for simulation of sheet metal forming. International Journal of Solids and Structures,69–70, 370–382.

Yoshida, F., Hamasaki, H., & Uemori, T. (2013). A user-friendly 3D yield function to describe anisotropy of steel sheets. International Journal of Plasticity,45, 119–139.

Tang, S. C., Pan, J. (2007). Mechanics modeling of sheet metal forming. Warrendale: SAE International. https://doi.org/10.4271/r-321. ISBN 978-0-7680-0896-8.

Safaei, M., Yoon, J. W., & De Waele, W. (2014). Study on the definition of equivalent plastic strain under non-associated flow rule for finite element formulation. International Journal of Plasticity,58, 219–238.

Stoughton, T. B., & Yoon, J. W. (2009). Anisotropic hardening and non-associated flow in proportional loading of sheet metals. International Journal of Plasticity,25, 1777–1817.

Safaei, M., Zang, S. L., Lee, M. G., & De Waele, W. (2013). Evaluation of anisotropic constitutive models: Mixed anisotropic hardening and non-associated flow rule approach. International Journal of Mechanical Sciences,73, 53–68.

Cardoso, R. P. R., & Yoon, J. W. (2009). Stress integration method for a nonlinear kinematic/isotropic hardening model and its characterization based on polycrystal plasticity. International Journal of Plasticity,25, 1684–1710.

Ito, K., Mori, N., Uemura, G., Oya, T., & Yanagimoto, J. (2013). Developement of the stress rate dependence constitutive model to plastic anisotropy. Proceedings of IDDRG,2013, 107–112.

Oya, T., Yanagimoto, J., Ito, K., Uemura, G., & Mori, N. (2014). Material model based on non-associated flow rule with higher order yield function for anisotropic metals. ICTP 2014 Procedia Engineering,81, 1210–1215.

Park, T., & Chung, K. (2012). Non-associated flow rule with symmetric stiffness modulus for isotropic-kinematic hardening and its application for earing in circular cup drawing. International Journal of Solids and Structures,49, 3582–3593.

Simo, J. C., & Hughes, T. J. R. (1998). Computational inelasticity, interdisciplinary applied mathematics. New York: Springer. ISBN 0387975209.

Safaei, M., Lee, M. G., & De Waele, W. (2015). Evaluation of stress integration algorithms for elastic–plastic constitutive models based on associated and non-associated flow rules. Computer Methods in Applied Mechanics and Engineering,295, 414–445.

Yoon, J. W., Yang, D. Y., & Chung, K. (1999). Elasto-plastic finite element method based on incremental deformation theory and continuum based shell elements for planar anisotropic sheet materials. Computer Methods in Applied Mechanics and Engineering,174, 23–56.

Yoon, J. W., Barlat, F., Dick, R. E., Chung, K., & Kang, T. J. (2004). Plane stress yield function for aluminum alloy sheets—Part II: FE formulation and its implementation. International Journal of Plasticity,20, 495–522.

ISO 6892-1:2016 Metallic materials—tensile testing—Part 1: Method of test at room temperature.

Merklein, M., & Biasutti, M. (2011). Forward and reverse simple shear test experiments for material modeling in forming simulations. In Special edition: 10th international conference on technology of plasticity, ICTP 2011 (pp. 702–707).

Yoon, J. W., & Barlat, F. (2006). Modeling and simulation of the forming of aluminum sheet alloys. In ASM Handbook, Metalworking: Sheet Forming, Vol. 14B (pp. 792–826). Materials Park: ASM International.

Yoon, J. W., Barlat, F., Dick, R. E., & Karabin, M. E. (2006). Prediction of six or eight ears in a drawn cup based on a new anisotropic yield function. International Journal of Plasticity,22, 174–193.

Yoon, J. W., Barlat, F., Chung, K., Pourboghrat, F., & Yang, D. Y. (2000). Earing predictions based on asymmetric nonquadratic yield function. International Journal of Plasticity,16, 1075–1104.

Kuwabara, T., Mori, T., Asano, M., Hakoyama, T., & Barlat, F. (2017). Material modeling of 6016-O and 6016-T4 aluminum alloy sheets and application to hole expansion forming simulation. International Journal of Plasticity,93, 164–186.

Acknowledgements

This investigation was conducted as part of a corporate social program (Based Technologies for Future Robots) supported by NIDEC Corporation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

For this multistage method, each plastic correction step is divided into k substeps. The non-linear equations for the sub-steps are

with

where \({{\Psi }}^{j}\) is a prescribed sub-potential residual value at the jth sub-step and it is adjustable in accordance with simulation case.

Each sub-step includes complete Newton–Raphson iterations. At the beginning of the jth sub-step, the initial direction \({\boldsymbol{n}}^{(j)}\) is estimated from the direction \({\boldsymbol{n}}^{(j - 1)}\) at the previous sub-step. The iteration is completed when the stress is driven onto the auxiliary yield surface. Finally, this procedure is finished when \({{\Psi }} = {{\Psi }}^{(k)} = 0\) and the plastic strain increment remains normal to the yield surface at the final stress \(\varvec{\sigma}_{{{\text{n}} + 1}}\). The iteration procedure for the jth sub-step is given as:

where

and

The following residuals are defined as:

To perform Newton–Raphson iterations, the above three functions are linearized with respect to the plastic strain increment \(d\bar{\varepsilon }^{p}\) at each iteration, giving

By substituting Eqs. (II) and (III) into Eq. (I) and rearranging, the following expression is obtained:

\(d{{\Delta }}\lambda_{(k)}\) represents the incremental change in the factor \(d\lambda_{(k)}\) at the kth iteration. The iterative change is fully defined by Eqs. (29) and (30). Thus, the variables can be updated as follows:

Rights and permissions

About this article

Cite this article

Wu, B., Ito, K., Mori, N. et al. Constitutive Equations Based on Non-associated Flow Rule for the Analysis of Forming of Anisotropic Sheet Metals. Int. J. of Precis. Eng. and Manuf.-Green Tech. 7, 465–480 (2020). https://doi.org/10.1007/s40684-019-00032-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-019-00032-5