Abstract

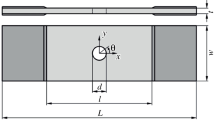

In this paper, a multiscale analysis strategy was proposed to analyze the failure behaviors of open-hole compressive (OHC) CFRP laminates. Micro-level intralaminar failure was defined in the constituents (fiber and matrix) with a modified micromechanics failure theory. In the multiscale stress transformation, the effect of thermal residual stress was considered using constant thermal amplification factor. Meanwhile, macro-level interlaminar failure was defined with cohesive elements. Based on the simulated and experimental results, the sub-laminate scaled OHC laminates of the stacking sequence [45/0/−45/90]4s were studied at different temperatures. The established multiscale model showed good precision in the strength and failure mode predictions. Transverse throughout damage at the hole section led to the final failure. As the temperature increased, the damage process began at a lower load level and the strength of the laminates decreased significantly. Stiffness reductions and small load drops were more likely to occur before final failure. The differences in the delamination size among all interfaces tended to be smaller. Besides, matrix failure lagged under shear loading conditions if the thermal residual stress was neglected in the multiscale analysis.

Similar content being viewed by others

References

Orifici, A.C., Herszberg, I., Thomson, R.S.: Review of methodologies for composite material modelling incorporating failure. Compos. Struct. 86, 194–210 (2008)

Tsai, S.W., Wu, E.M.: A general theory of strength for anisotropic materials. J. Compos. Mater. 5, 58–80 (1971)

Hashin, Z.: Failure criteria for unidirectional fiber composites. J. Appl. Mech. 47, 329–334 (1980)

Meng, Q., Wang, Z.: Micromechanical modeling of impact damage mechanisms in unidirectional composite laminates. Appl. Compos. Mater. 23, 1099–1116 (2016)

Tay, T.E., Tan, S.H.N., Tan, V.B.C., Gosse, J.H.: Damage progression by the element-failure method (EFM) and strain invariant failure theory (SIFT). Compos. Sci. Technol. 65, 935–944 (2005)

Tay, T.E., Liu, G., Tan, V.B.C., Sun, X.S., Pham, D.C.: Progressive failure analysis of composites. J. Compos. Mater. 42, 1921–1966 (2008)

Ha, S.K., Huang, Y., Han, H.H., Jin, K.K.: Micromechanics of failure for ultimate strength predictions of composite laminates. J. Compos. Mater. 44, 2347–2361 (2010)

Sun, X.S., Tan, V.B.C., Tay, T.E.: Micromechanics-based progressive failure analysis of fibre-reinforced composites with non-iterative element-failure method. Comput. Struct. 89, 1103–1116 (2011)

Cai, H., Miyano, Y., Nakada, M.: Long-term open-hole compression strength of CFRP laminates based on strain invariant failure theory. J. Thermoplast. Compos. Mater. 22, 63–81 (2009)

Ha, S.K., Jin, K.K., Huang, Y.C.: Micro-mechanics of failure (MMF) for continuous fiber reinforced composites. J. Compos. Mater. 42, 1873–1895 (2008)

Sihn, S.: Strength prediction of composites using micromechanics-based failure. In: Tsai, S.W. (eds) Strength & Life of Composites, pp. 6-29–6-51. JEC-Composites, Stanford University (2008)

Lee, J., Soutis, C.: Measuring the notched compressive strength of composite laminates: specimen size effects. Compos. Sci. Technol. 68, 2359–2366 (2008)

Lee, H.K., Kim, B.R.: Numerical characterization of compressive response and damage evolution in laminated plates containing a cutout. Compos. Sci. Technol. 67, 2221–2230 (2007)

Soutis, C., Filiou, C.: Stress distributions around holes in composite laminates subjected to biaxial loading. Appl. Compos. Mater. 5, 365–378 (1998)

Soutis, C.: Compressive strength of composite laminates with an open hole: effect of ply blocking. J. Compos. Mater. 47, 2503–2512 (2013)

Su, Z.C., Tay, T.E., Ridha, M., Chen, B.Y.: Progressive damage modeling of open-hole composite laminates under compression. Compos. Struct. 122, 507–517 (2015)

Suemasu, H., Takahashi, H., Ishikawa, T.: On failure mechanisms of composite laminates with an open hole subjected to compressive load. Compos. Sci. Technol. 66, 634–641 (2006)

Suemasu, H., Naito, Y., Gozu, K., Aoki, Y.: Damage initiation and growth in composite laminates during open hole compression tests. Adv. Compos. Mater. 21, 209–220 (2012)

Jin, K.K., Huang, Y.C., Lee, Y.H., Ha, S.K.: Distribution of micro stresses and interfacial tractions in unidirectional composites. J. Compos. Mater. 42, 1825–1849 (2008)

Li, X., Guan, Z.D., Li, Z.S., Liu, L.: A new stress-based multi-scale failure criterion of composites and its validation in open hole tension tests. Chin. J. Aeronaut. 27, 1430–1441 (2014)

Turon, A., Dávila, C.G., Camanho, P.P., Costa, J.: An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models. Eng. Fract. Mech. 74, 1665–1682 (2007)

Aymerich, F., Dore, F., Priolo, P.: Prediction of impact-induced delamination in cross-ply composite laminates using cohesive interface elements. Compos. Sci. Technol. 68, 2383–2390 (2008)

Reeder, J.R. An evaluation of mixed-mode delamination. Hampton, Virginia: Langley Research Center, National Aeronautic and Space Administration (NASA); 1992. Report No: NASA/TM-1992–104210

Dávila, C.G., Camanho, P.P., Moura, M.F.: Mixed-mode decohesion elements for analysis of progressive delamination. Proceedings of the 42nd AIAA/ASME/ASCE/AHS/ASC structures, structure dynamics, and materials conference and exhibit, 45–55 Seattle (2001)

Jiang, W.G., Hallett, S.R., Green, B.G., Wisnom, M.R.: A concise interface constitutive law for analysis of delamination and splitting in composite materials and its application to scaled notched tensile specimens. Int. J. Numer. Methods Eng. 69, 1982–1995 (2007)

Pinho, S.T., Iannucci, L., Robinson, P.: Formulation and implementation of decohesion elements in an explicit finite element code. Compos. A: Appl. Sci. Manuf. 37, 778–789 (2006)

Harper, P.W., Hallett, S.R.: A fatigue degradation law for cohesive interface elements - development and application to composite materials. Int. J. Fatigue. 32, 1774–1787 (2010)

Mayes, J.S., Hansen, A.C.: Composite laminate failure analysis using multicontinuum theory. Compos. Sci. Technol. 64, 379–394 (2004)

Brewer, J.C., Lagace, P.A.: Quadratic stress criterion for initiation of delamination. J. Compos. Mater. 22, 1141–1155 (1988)

Davila, C.G., Johnson, E.R.: Analysis of delamination initiation in postbuckled dropped-ply laminates. AIAA J. 31, 721–727 (1993)

Alfano, G., Crisfield, M.A.: Finite element interface models for the delamination analysis of laminated composites: mechanical and computational issues. Int. J. Numer. Methods Eng. 50, 1701–1736 (2001)

ASTM D5528. Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites. West Conshohocken, PA, USA: American Society for Testing and Materials (ASTM) 2002

ASTM D7095. Standard test method for determination of the mode II interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites. West Conshohocken, PA, USA: American Society for Testing and Materials (ASTM) 2014

Hillerborg, A., Modéer, M., Petersson, P.E.: Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 6, 773–781 (1976)

Iarve, E.V., Pagano, N.J.: Singular full-field stresses in composite laminates with open holes. Int. J. Solids Struct. 38, 1–28 (2001)

Wisnom, M.R., Hallett, S.R., Soutis, C.: Scaling effects in notched composites. J. Compos. Mater. 44, 195–210 (2010)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Z., Guan, Z., Tan, R. et al. Analysis of Open-Hole Compressive CFRP Laminates at Various Temperatures Based on a Multiscale Strategy. Appl Compos Mater 26, 923–944 (2019). https://doi.org/10.1007/s10443-019-9759-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-019-9759-8