Abstract

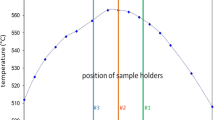

For 9–12Cr ferritic–martensitic steels in supercritical water, the dependencies of the thicknesses of three oxide layers (diffusion, inner, and outer layers) on each of seven principal independent variables were separately investigated using three supervised artificial neural networks (ANN) and fuzzy curve analyses. The latter were employed to evaluate the relative significances of independent variables, indicating that on the whole, temperature and exposure time are the most important variables, while the oxide dispersion strengthening (ODS) comes in the first place for the thickness of the diffusion layer. A thicker diffusion layer occurs easily at intermediate temperature approximately 600 °C and/or on ODS steels, due to higher growth rate of the barrier layer than that of the outer layer. The periodic growth of the diffusion layer, including the “shrinking”/“thickening” stages, was revealed by ANN prediction, which may be the basic cause of periodic pore-assembled layers within the inner layer. Finally, the physicochemical basis of classical point defect model was extended to describe the growth of oxide scales for explaining the ANN predictions at the atomic level. The growth of the inner layer into the metal is attributed to the inward transport of oxide ions (actually via outward transport of oxygen vacancies), while the outward transport of cations through the inner layer via a cation vacancy mechanism or as interstitials results in the thickening of the outer layer. The periodic variation in oxygen potentials at the diffusion/inner layer interface is responsible for the periodic growth of the diffusion layer. The iron caves at the inner–diffusion interface left behind by the generation reaction of cation interstitials may be the intrinsic sources of pores within the inner layer.

Graphical Abstract

Similar content being viewed by others

References

R. Viswanathan, J. Sarver, and J. M. Tanzosh, Journal of Materials Engineering and Performance 15, 255–274 (2006).

G. R. Holcomb, Oxidation of Metals 82, 271–295 (2014).

S. Bsat, B. Xiao, X. Huang, and S. Penttilä, Oxidation of Metals 89, 151–163 (2018).

Nuclear Energy Research Advisory Committee and Gen IV International Forum: A Technology Roadmap for Generation IV Nuclear Energy Systems, DOE, US (2002).

P. Ampornrat, G. Gupta, and G. S. Was, Journal of Nuclear Materials 395, 30–36 (2009).

G. S. Was, et al. Journal of Nuclear Materials 371, 176–201 (2007).

K. Yin, S. Qiu, R. Tang, Q. Zhang, and L. Zhang, Journal of Supercritical Fluids 50, 235–239 (2009).

L. Tan, Y. Yang, and T. R. Allen, Corrosion Science 48, 3123–3138 (2006).

P. Ampornrat and G. S. Was, Journal of Nuclear Materials 371, 1–17 (2007).

T. R. Allen, Y. Chen, X. Ren, K. Sridharan, L. Tan, G. S. Was, E. West, and D. Guzonas, in Comprehensive Nuclear Materials, eds. R. J. M. Konings, (Elsevier, Oxford, 2012), p. 279–326.

Y. H. Li, S. Z. Wang, X. D. Li, and J. M. Lu, Advanced Materials Research 908, 67–71 (2014).

L. Sun and W. P. Yan, Advances in Materials Science and Engineering 12, (2017).

Z. Zhang, Z. F. Hu, L. F. Zhang, K. Chen, and P. M. Singh, Journal of Nuclear Materials 498, 89–102 (2018).

Y. Li, et al., Corrosion Science 135, 136–146 (2018).

N. Q. Zhang, Z. L. Zhu, H. Xu, X. P. Mao, and J. Li, Corrosion Science 103, 124–131 (2016).

L. Tan, X. Ren, and T. R. Allen, Corrosion Science 52, 1520–1528 (2010).

Z. L. Zhu, H. Xu, D. F. Jiang, and N. Q. Zhang, Oxidation of Metals 86, 483–496 (2016).

J. Bischoff, A. T. Motta, C. Eichfeld, R. J. Comstock, G. Cao, and T. R. Allen, Journal of Nuclear Materials 441, 604–611 (2013).

J. Bischoff and A. T. Motta, Journal of Nuclear Materials 424, 261–276 (2012).

N. Zhang, H. Xu, B. Li, Y. Bai, and D. Liu, Corrosion Science 56, 123–128 (2012).

J. Bischoff and A. T. Motta, Journal of Nuclear Materials 430, 171–180 (2012).

J. Bischoff, A. T. Motta, and R. J. Comstock, Journal of Nuclear Materials 392, 272–279 (2009).

R. Rojas, Neural Networks: A Systematic Introduction (Springer, Berlin, 1996_.

J. Shi, J. Wang, and D. D. Macdonald, Corrosion Science 92, 217–227 (2015).

M. K. Cavanaugh, R. G. Buchheit, and N. Birbilis, Corrosion Science 52, 3070–3077 (2010).

L. Yinghua and G. A. Cunningham, IEEE Transactions on Fuzzy Systems 3, 190–198 (1995).

A. H. Sung, Expert Systems with Applications 15, 405–411 (1998).

Y. Li, T. Xu, S. Wang, B. Fekete, J. Yang, J. Yang, J. Qiu, A. Xu, J. Wang, and Y. Xu, Materials 12, 409 (2019).

W. H. Gao, X. L. Guo, Z. Shen, and L. F. Zhang, Journal of Nuclear Materials 486, 1–10 (2017).

J. Yuan, X. Wu, W. Wang, S. Zhu, and F. Wang, Oxidation of Metals 79, 541–551 (2013).

F. Hamdani and T. Shoji, Oxidation of Metals 89, 319–330 (2018).

Y. Li, D. D. Macdonald, J. Yang, and S. Wang, (2018) (in preparation).

V. V. Sagaradze, et al., Journal of Nuclear Materials 295, 265–272 (2001).

J. H. Lee, et al., Journal of Nuclear Materials 417, 1225–1228 (2011).

Y. Li, et al., International Journal of Hydrogen Energy 41, 15764–15771 (2016).

L. Tan, M. T. Machut, K. Sridharan, and T. R. Allen, Journal of Nuclear Materials 371, 161–170 (2007).

A. Rahmel and J. Tobolski, Corrosion Science 5, 333–346 (1965).

X. Zhong, X. Wu, and E.-H., Han, The Journal of Supercritical Fluids 72, 68–77 (2012).

H. Li, Q. Cao, and Z. Zhu, Corrosion Engineering, Science and Technology 53, 293–301 (2018).

C. Y. Chao, L. F. Lin, and D. D. Macdonald, Journal of the Electrochemical Society 128, 1187–1194 (1981).

J. Robertson, Corrosion Science 32, 443–465 (1991).

L. Tan, Y. Yang, and T. R. Allen, Corrosion Science 48, 4234–4242 (2006).

H. Zhou, J. Qu, and M. Cherkaoui, Mechanics of Materials 42, 63–71 (2010).

Acknowledgements

The authors are happy to acknowledge financial support from the National Key Research and Development Program of China (No. 2016YFC0801904), DOE-NEUP Award (DE-NE0008541) of USA, the Fundamental Research Funds for the Central Universities [xjj2018201] and [xjj2018006] and the Projects from National Natural Science Foundation of China [51871179]. Yanhui Li also appreciates China Scholarship Council (CSC) to support his study at University of California at Berkeley.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Xu, T., Wang, S. et al. Predictions and Analyses on the Growth Behavior of Oxide Scales Formed on Ferritic–Martensitic in Supercritical Water. Oxid Met 92, 27–48 (2019). https://doi.org/10.1007/s11085-019-09912-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-019-09912-2