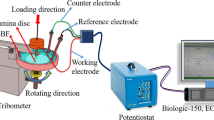

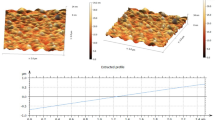

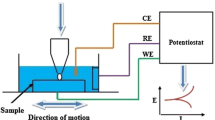

This study aims to examine the wear performance and electrochemical corrosion properties of Ti15Mo alloy produced by mechanical alloying (MA) in simulated body fluid (SBF) environment. Ti15Mo alloy was produced by milling in a mechanical alloying device for 120 min. The alloys produced are examined using SEM, X-ray diffraction, hardness and density measurements. Three different loads, four different sliding distances and 1 m · sec–1 sliding speed were used in the tests performed in SBF environment. Corrosion tests were carried out using potentiodynamic polarization technique, cyclic polarization measurement at 37°C body temperature, in SBF, with a scan interval of ±750 mV and scan rate of 1 mV/sec. Density and hardness measurement results of MA’ed Ti15Mo alloy are 4.93 g/cm3 and 299.5 HV, respectively. As a result of increasing the load applied during the wear tests, the resistance of the samples against wear has decreased and the amount of wear has increased. Corrosion tests showed that the potentiodynamic polarization parameters were 36.969 mA/cm2 for Icorr value and 0.54448 mmpy for corrosion rate. Corrosion tests made in the environment of SBF and at body temperature revealed that there was very little pitting corrosion observed in MA’ed Ti15Mo alloy.

Similar content being viewed by others

References

D. Mareci, R. Chelariu, D.M. Gordin, M. Romas, D. Sutiman, and T. Gloriant, “Effect of Mo content on electrochemical behaviour of TiMo alloys for dental applications,” Mater. Corros., Vol. 61, No. 10, 829–837 (2010.).

D.R.C. McLachlan, “Aluminium and the risk for Alzheimer’s disease,” Environmetrics, 6, No. 3, 233–275 (1995).

M. Niinomi, “Mechanical biocompatibilities of titanium alloys for biomedical applications,” J. Mech. Behav. Biomed. Mater., 1, No. 1, 30–42 (2008).

M. Geetha, A.K. Singh, R. Asokamani, and A.K. Gogia, “Ti based biomaterials, the ultimate choice for orthopaedic implants – A review,” Prog. Mater. Sci., 54, No. 3, 397–425 (2009).

J.R.S.M. Júnior, R.A. Nogueira, R.O. de Araújo, T.A.G. Donato, V.E. Arana-Chavez, A.P.R.A. Claro, J.C.S. Moraes, M.A.R. Buzalaf, and C.R. Grandini, “Preparation and characterization of Ti–15Mo alloy used as biomaterial,” Mater. Res., 14, No. 1, 107–112 (2011).

W.F. Ho, C.P. Ju, and J.C. Lin, “Structure and properties of cast binary Ti–Mo alloys,” Biomaterials, 20, No. 22, 2115–2122 (1999).

N.T.C. Oliveira and A.C. Guastaldi, “Electrochemical stability and corrosion resistance of Ti–Mo alloys for biomedical applications,” Acta Biomater., 5, No. 1, 399–405 (2009).

L. Bolzoni, E.M. Ruiz-Navas, and E. Gordo, “Feasibility study of the production of biomedical Ti–6Al–4V alloy by powder metallurgy,” Mater. Sci. Eng. C., 49, 400–407 (2015).

V.K. Balla, S. Bodhak, S. Bose, and A. Bandyopadhyay, “Porous tantalum structures for bone implants: fabrication, mechanical and in vitro biological properties,” Acta Biomater., 6, No. 8, 3349–3359 (2010).

P. Mohan, A. Amigo, and V. Amigo, “Effects of Fe and Mo content on the microstructure and mechanical properties of Ti–Mo based alloys prepared by elemental blend and mechanical alloying technique,” in: PM 16 Int. Conf. Powder Metall. Part. Mater., Pune, India (2016), pp. 25–31.

M. Wagner, “Medium-term results of a modern metal-on-metal system in total hip replacement,” Arthroplasty 2000, 49–62 (2001).

A. Choubey, B. Basu, and R. Balasubramaniam, “Tribological behaviour of Ti-based alloys in simulated body fluid solution at fretting contacts,” Mater. Sci. Eng. A., 379, Nos. 1–2, 234–239 (2004).

T. Kokubo, H. Kushitani, S. Sakka, T. Kitsugi, and T. Yamamuro, “Solutions able to reproduce in vivo surface-structure changes in bioactive glass-ceramic A-W,” J. Biomed. Mater. Res., 24, No. 6, 721–734 (1990).

S. Kumar and T.S. Narayanan, “Electrochemical characterization of β-Ti alloy in Ringer’s solution for implant application,” J. Alloys Compd.. 479, Nos. 1–2, 699–703 (2009).

L.J. Xu, S.L. Xiao, J. Tian, and Y.Y. Chen, “Microstructure, mechanical properties and dry wear resistance of β-type Ti–15Mo–xNb alloys for biomedical applications,” Trans. Nonferrous Met. Soc. China, 23, No. 3, 692–698 (2013).

E.B. Lee, M.K. Han, B.J. Kim, H.J. Song, and Y.J. Park, “Effect of molybdenum on the microstructure, mechanical properties and corrosion behavior of Ti alloys,” Int. J. Mater. Res., 105, No. 9, 847–853 (2014).

D. Özyürek and S. Tekeli, “Wear properties of titanium and Ti6Al4V alloy by mechanical milling,” High Temp. Mat. Process, 30, Nos. 1–2, 175–180 (2011).

B.K.C. Ganesh, N. Ramanaih, N. Bhuvaneswari, and S.V.N. Pammi, “Effect of Hank’s solution and shot blasting on the tribological behavior of titanium implant alloys,” Int. J. Mater. Biomater. App., 2, No. 1, 5–11 (2012).

J.H.H. Bongaerts, D. Rossetti, and J.R. Stokes, “The lubricating properties of human whole saliva,” Tribology Lett., 27, No. 3, 277–287 (2007).

D. Özyürek, T. Tunçay, H. Evlen, and I. Çiftçi, “Synthesis, characterization and dry sliding wear behavior of in–situ formed TiAl3 precipitate reinforced A356 alloy produced by mechanical alloying method,” Mat. Res. 18, No. 4, 813–820 (2015).

I. Simsek and D. Ozyürek, “An investigation of the effect of high-energy milling time of Ti6Al4V biomaterial on the wear performance in the simulated body fluid environment,” Powder Metall., 60, No. 5, 384–392 (2017).

C. Suryanarayana, “Mechanical alloying and milling,” Prog. Mater. Sci., 46, Nos. 1–2, 1–184 (2001).

G. Ren, Z. Zhang, X. Zhu, X. Men, W. Jiang, and W. Liu, “Sliding wear behaviors of Nomex fabric/phenolic composite under dry and water-bathed sliding conditions,” Friction, 2, No. 3, 264–271 (2014).

D. Mareci, G. Ungureanu, D.M. Aelenei, and J.C. Mirza Rosca, “Electrochemical characteristics of titanium based biomaterials in artificial saliva,” Mater. Corros., 58, No. 11, 848–856 (2007).

M. Szklarska, G. Dercz, J. Rak, W. Simka, and B. Losiewicz, “The influence of passivation type on corrosion resistance of Ti15Mo alloy in simulated body fluids,” Arch. Metall Mater., 60, No. 4, 2687–2694 (2015).

D.J. Blackwood, A.W.C. Chua, K.H.W. Seah, R. Thampuran, and S.H. Teoh, “Corrosion behaviour of porous titaniumgraphite composites designed for surgical implants,” Corros. Sci., 42, No. 3, 481–503 (2000).

R. Bhola, C. Chandra, F.M. Alabbas, S. Kundu, B. Mishra, and D.L. Olson, “Corrosion response of Ti6Al4V and Ti15Mo dental implant alloys in the presence of listerine oral rinse,” Int. J. Corros., 2013, 1–7 (2013).

D. Mareci, R. Chelariu, I. Dan, D.M. Gordin, and T. Gloriant, “Corrosion behaviour of β-Ti20Mo alloy in artificial saliva,” J. Mater. Sci. Mater. Med., 21, No. 11, 2907–2913 (2010).

E. Bardal, Corrosion and Protection, London, Springer-Verlag Ltd. (2004), 315 pp.

D. Mareci, R. Chelariu, S. Ivanescu, D.M. Gordin, I. Cretescu, and T. Gloriant, “Electrochemical behavior of a new titanium alloy for dental applications,” Rev. Chim., 60, No. 8, 787–793 (2009).

E. Vasilescu, P. Drob, D. Raducanu, I. Cinca, D. Mareci, J.M.C. Moreno, M. Popa, C. Vasilescu, and J.C.M. Roscad, “Effect of thermo-mechanical processing on the corrosion resistance of Ti6Al4V alloys in biofluids,” Corros. Sci., 51, No. 12, 2885–2896 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkova Metallurgiya, Vol. 58, Nos. 7–8 (528), pp. 98–108, 2019.

Rights and permissions

About this article

Cite this article

Şimşek, I., Özyürek, D. Investigation of Wear and Corrosion Behaviors of Ti15Mo Alloy Produced by Mechanical Alloying Method in SBF Environment. Powder Metall Met Ceram 58, 446–454 (2019). https://doi.org/10.1007/s11106-019-00094-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-019-00094-9