Abstract

The occurrence of blistering and the formation of bubbles in matrices after a sudden pressure drop is a well-known phenomenon in many fields, including in the petroleum industry (“explosive decompression failure”), in diving (decompression sickness), in the infrastructure of hydrogen fuel cells, in the foaming of polymers, and in the high-pressure processing of food. This usually undesirable effect is caused by the increased absorption of gas in the polymer under high-pressure conditions and the subsequent supersaturation and increase in free energy on rapid pressure release. The exact mechanisms of the resulting expansion of gas, and hence the formation of bubbles, are not fully understood. Regarding the high-pressure processing of food where pressures of up to 6000 bar are reached at moderate temperatures, little information is available about the key factors involved in decompression failure. This review summarizes results and findings from relevant research areas to understand polymer decompression failure. The first part of this review describes the transport properties of gases in polymers under high pressure (sorption and desorption, diffusion coefficient, and permeability coefficient). The second part focuses on damage mechanisms and discusses parameters such as material properties, the nature of the gas, and process conditions (e.g., temperature, decompression rate). Knowledge gaps and proposed research are highlighted.

Similar content being viewed by others

Abbreviations

- APET:

-

Amorphous polyethylene terephthalate

- BD:

-

Bubble density = bubbles/blisters per volume of the matrix

- BS:

-

Bubble size, volume or diameter

- DCS:

-

Decompression sickness

- EPDM:

-

Ethylene propylene diene, M-class

- GR:

-

Bubble growth rate

- HPP:

-

High-pressure processing

- MAP:

-

Modified atmosphere packaging

- NBR:

-

Acrylonitrile butadiene rubber

- PA11:

-

Polyamide 11

- PC:

-

Polycarbonate

- PEEK:

-

Poly(ether-ether-ketone)

- PE-HD:

-

Polyethylene high density

- PE-LD:

-

Polyethylene low density

- PET:

-

Polyethylene terephthalate

- PGA:

-

Poly(glycolic acid)

- PLLA:

-

Poly l-lactic acid

- PLG:

-

Copolymer of d,l-lactide and glycolide (varying content)

- P max :

-

Maximum applied pressure in the system

- PMMA:

-

Poly(methyl methacrylate)

- PP:

-

Polypropylene

- PS:

-

Polystyrene

- P SS :

-

Supersaturation pressure

- PSU:

-

Polysulfone

- PTFE:

-

Polytetrafluorethylene (Teflon)

- PVAc or PVA:

-

Poly(vinyl acetate)

- PVC:

-

Poly(vinyl chloride)

- PVDF:

-

Poly(vinylidene fluoride)

- scrCO2 :

-

Supercritical carbon dioxide

- SRR:

-

Supersaturation ratio

- STP:

-

Standard temperature (273 K) and pressure (1.013 bar)

- TiO2 :

-

Titanium dioxide

- T g :

-

Glass transition temperature

- T m :

-

Melting temperature

- VMQ:

-

Vinyl methyl polysiloxane

- XDF:

-

Explosive decompression failure

References

Al-Nehlawi A, Guri S, Guamis B, Saldo J (2014) Synergistic effect of carbon dioxide atmospheres and high hydrostatic pressure to reduce spoilage bacteria on poultry sausages. LWT-Food Sci Technol 58(2):404–411

Corwin H, Shellhammer TH (2002) Combined carbon dioxide and high pressure inactivation of pectin methylesterase, polyphenol oxidase, Lactobacillus plantarum and Escherichia coli. J Food Sci 67(2):697–701

Bull MK, Steele RJ, Kelly M, Olivier SA, Chapman B (2010) Packaging under pressure: effects of high pressure, high temperature processing on the barrier properties of commonly available packaging materials. Innovative Food Sci Emerg Technol 11(4):533–537

Fairclough JPA, Conti M (2009) Influence of ultra-high pressure sterilization on the structure of polymer films. Packag Technol Sci 22(5):303–310. https://doi.org/10.1002/pts.858

Fleckenstein BS, Sterr J, Langowski H-C (2014) The effect of high pressure processing on the integrity of polymeric packaging—analysis and categorization of occurring defects. Packag Technol Sci 27(2):83–103. https://doi.org/10.1002/pts.2018

Götz J, Weisser H (2002) Permeation of aroma compounds through plastic films under high pressure: in-situ measuring method. Innovative Food Sci Emerg Technol 3(1):25–31

Koutchma T, Song Y, Setikaite I, Juliano P, Barbosa-Cánovas GV, Dunne CP, Patazca E (2009) Packaging evaluation for high-pressure high-temperature sterilization of shelf-stable foods. J Food Process Eng 33(6):1097–1114. https://doi.org/10.1111/j.1745-4530.2008.00328.x

Masuda M, Saito Y, Iwanami T, Hirai Y (1992) Effects of hydrostatic pressure on packaging materials for food. In: Balny C, Hayashi R, Heremans K, Masson P (eds) High pressure and biotechnology, vol 224. John Libbey EUROTEXT, Montrouge, pp 545–547

Richter T (2011) Der Einfluss hohen hydrostatischen Drucks auf polymere thermoplastische Lebensmittelverpackungen, München, Techn. Univ., Diss., 2011

Richter T, Sterr J, Jost V, Langowski H-C (2010) High pressure-induced structural effects in plastic packaging. High Pressure Res 30(4):555–566. https://doi.org/10.1080/08957959.2010.531722

Sterr J, Fleckenstein BS, Langowski H-C (2015a) The effect of high pressure processing on tray packages with modified atmosphere. Food Eng Rev 7(2):209–221. https://doi.org/10.1007/s12393-014-9081-z

Baudet C, Grandidier J-C, Cangémi L (2009) A two-phase model for the diffuso-mechanical behaviour of semicrystalline polymers in gaseous environment. Int J Solids Struct 46(6):1389–1401. https://doi.org/10.1016/j.ijsolstr.2008.11.010

Boyer SAE, Klopffer M-H, Martin J, Grolier J-PE (2007) Supercritical gas–polymer interactions with applications in the petroleum industry. Determination of thermophysical properties. J Appl Polym Sci 103(3):1706–1722. https://doi.org/10.1002/app.25085

Grolier J-PE, Boyer SAE (2007) Solubility of gases in polymers. In: Letcher TM (ed) Development and applications in solubility. RSC Pub, Cambridge, pp 249–260

Barth RR, Simmons KL, San Marchi C (2013) Polymers for hydrogen infrastructure and vehicle fuel systems. Applications, properties, and gap analysis, Albuquerque, New Mexico, U.S.A

Koga A, Yamabe T, Sato H, Uchida K, Nakayama J, Yamabe J, Nishimura S (2013) A visualizing study of blister initiation behavior by gas decompression. Tribol Online 8(1):68–75

Flook V (2000) The physics and physiology of decompression. Eur J Underwater Hyperb Med 1(1):8–13

Flaconnèche B, Martin J, Klopffer M-H (2001b) Transport properties of gases in polymers: experimental methods. Oil Gas Sci. Technol. – Rev. IFP Energ Nouvelles 56(3):245–259. https://doi.org/10.2516/ogst:2001022

Barrer RM (1951) Diffusion in and through solids. The Cambridge Series of Physical Chemistry. University Press, Cambridge

Battino R, Clever HL (1966) The solubility of gases in liquids. Chem Rev 66(4):395–463. https://doi.org/10.1021/cr60242a003

Prausnitz JM, Lichtenthaler RN, Azevedo EGd (1999) Molecular thermodynamics of fluid-phase equilibria, 3rd ed. Prentice-Hall International Series in the Physical and Chemical Engineering Sciences. Prentice Hall PTR, Upper Saddle River

Sander R (2015) Compilation of Henry’s law constants (version 4.0) for water as solvent. Atmos Chem Phys 15(8):4399–4981. https://doi.org/10.5194/acp-15-4399-2015

Wedler G (1997) Lehrbuch der physikalischen Chemie, 4., völlig überarb. und erw. Aufl. Wiley-VCH, Weinheim

Atkins PW, de Paula J (2006) Physikalische Chemie, 4., vollst. überarb. Aufl. VCH, Weinheim [u.a]

Sarrasin F, Memari P, Klopffer M-H, Lachet V, Taravel Condat C, Rousseau B, Espuche E (2015) Influence of high pressures on CH4, CO2 and H2S solubility in polyethylene. Experimental and molecular simulation approaches for pure gas and gas mixtures. Modelling of the sorption isotherms. J Membr Sci 490:380–388. https://doi.org/10.1016/j.memsci.2015.04.040

Enns T, Scholander PF, Bradstreet ED (1965) Effect of hydrostatic pressure on gases dissolved in water. J Phys Chem 69(2):389–391. https://doi.org/10.1021/j100886a005

Ludwig H, Macdonald AG (2005) The significance of the activity of dissolved oxygen, and other gases, enhanced by high hydrostatic pressure. Comp Biochem Physiol A Mol Integr Physiol 140(4):387–395. https://doi.org/10.1016/j.cbpb.2005.02.001

Spycher N, Pruess K, Ennis-King J (2003) CO2–H2O mixtures in the geological sequestration of CO2. I. Assessment and calculation of mutual solubilities from 12 to 100°C and up to 600 bar. Geochim Cosmochim Acta 67(16):3015–3031

Michaels AS, Bixler HJ (1961) Solubility of gases in polyethylene. J Polym Sci 50(154):393–412. https://doi.org/10.1002/pol.1961.1205015411

Scheichl R, Klopffer M-H, Benjelloun-Dabaghi Z, Flaconnèche B (2005) Permeation of gases in polymers: parameter identification and nonlinear regression analysis. J Membr Sci 254(1–2):275–293

Boyer SAE, Randzio SL, Grolier J-PE (2006) Thermal expansion of polymers submitted to supercritical CO2 as a function of pressure. J Polym Sci B Polym Phys 44(1):185–194. https://doi.org/10.1002/polb.20674

Budd PM, McKeown NB, Fritsch D (2005) Free volume and intrinsic microporosity in polymers. J Mater Chem 15(20):1977–1986. https://doi.org/10.1039/B417402J

Duncan B, Urquhart J, Roberts S (2005) Review of measurement and modelling of permeation and diffusion in polymers. NPL Report DEPC MPR 012, Middlesex

Fujita H (1961) Diffusion in polymer–diluent systems. Fortschritte Der Hochpolymeren-Forschung. Springer, In, pp 1–47

Mercea P (2008) Models for diffusion in polymers. In: Piringer OG, Baner AL (eds) Plastic packaging. Interactions with food and pharmaceuticals, 2nd edn. Wiley-VCH, Weinheim, pp 123–161

Vrentas JS, Duda JL (1977) Diffusion in polymer–solvent systems. I. Reexamination of the free-volume theory. J Polym Sci Polym Phys Ed 15(3):403–416

Vrentas JS, Vrentas CM, Duda JL (1993) Comparison of free-volume theories. Polym J 25(1):99–101. https://doi.org/10.1295/polymj.25.99

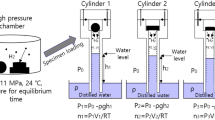

Sterr J, Rötzer K, Weck K, Wirth ALK, Fleckenstein BS, Langowski H-C (2015b) In-situ measurement of oxygen concentration under high pressure and the application to oxygen permeation through polymer films. J Chem Phys 143(11):114201. https://doi.org/10.1063/1.4931399

Hilic S, Boyer SAE, Pádua AAH, Grolier J-PE (2001) Simultaneous measurement of the solubility of nitrogen and carbon dioxide in polystyrene and of the associated polymer swelling. J Polym Sci B Polym Phys 39(17):2063–2070. https://doi.org/10.1002/polb.1181

Muth O, Hirth T, Vogel H (2001) Investigation of sorption and diffusion of supercritical carbon dioxide into poly(vinyl chloride). J Supercrit Fluids 19(3):299–306

Vieth WR (1991) Diffusion in and through polymers. Principles and applications. Hanser Publishers; Distributed in the USA and in Canada by Oxford University Press, Munich

Vieth WR, Howell JM, Hsieh JH (1976) Dual sorption theory. J Membr Sci 1(2):177–220. https://doi.org/10.1016/S0376-7388(00)82267-X

Tsujita Y (2003) Gas sorption and permeation of glassy polymers with microvoids. Prog Polym Sci 28(9):1377–1401

Chang S-H, Park S-C, Shim J-J (1998) Phase equilibria of supercritical fluid–polymer systems. J Supercrit Fluids 13(1–3):113–119. https://doi.org/10.1016/S0896-8446(98)00042-4

Bonavoglia B, Storti G, Morbidelli M, Rajendran A, Mazzotti M (2006) Sorption and swelling of semicrystalline polymers in supercritical CO2. J Polym Sci B Polym Phys 44(11):1531–1546

Sato Y, Fujiwara K, Takikawa T, Sumarno TS, Masuoka H (1999) Solubilities and diffusion coefficients of carbon dioxide and nitrogen in polypropylene, high-density polyethylene, and polystyrene under high pressures and temperatures. Fluid Phase Equilib 162(1–2):261–276. https://doi.org/10.1016/S0378-3812(99)00217-4

Berens AR, Huvard GS, Korsmeyer RW, Kunig FW (1992) Application of compressed carbon dioxide in the incorporation of additives into polymers. J Appl Polym Sci 46(2):231–242. https://doi.org/10.1002/app.1992.070460204

Tang M, T-B D, Chen Y-P (2004b) Sorption and diffusion of supercritical carbon dioxide in polycarbonate. J Supercrit Fluids 28(2–3):207–218. https://doi.org/10.1016/S0896-8446(03)00045-7

Tang M, Huang Y-C, Chen Y-P (2004a) Sorption and diffusion of supercritical carbon dioxide into polysulfone. J Appl Polym Sci 94(2):474–482. https://doi.org/10.1002/app.20895

Naito Y, Mizoguchi K, Terada K, Kamiya Y (1991) The effect of pressure on gas permeation through semicrystalline polymers above the glass transition temperature. J Polym Sci B Polym Phys 29(4):457–462

Kulkarni SS, Stern SA (1983) The diffusion of CO2, CH4, C2H4, and C3H8 in polyethylene at elevated pressures. J Polym Sci Polym Phys Ed 21(3):441–465. https://doi.org/10.1002/pol.1983.180210310

Flaconnèche B, Martin J, Klopffer M-H (2001a) Permeability, diffusion and solubility of gases in polythylene, polyamide 11 and poly(vinylidene fluoride). Oil Gas Sci. Technol. – Rev. IFP Energies Nouvelles 56(3):261–278

Lei Z, Ohyabu H, Sato Y, Inomata H, Smith RL (2007) Solubility, swelling degree and crystallinity of carbon dioxide–polypropylene system. J Supercrit Fluids 40(3):452–461. https://doi.org/10.1016/j.supflu.2006.07.016

Ru-Ting X, Xing-Yuan H (2015) Predictive calculation of carbon dioxide solubility in polymers. RSC Adv 5(94):76979–76986. https://doi.org/10.1039/C5RA15109K

Schnitzler J v, Eggers R (1999) Mass transfer in polymers in a supercritical CO2-atmosphere. J Supercrit Fluids 16(1):81–92

Briscoe BJ, Mahgerefteh H (1984) A novel technique for the quantitative measurement of gaseous uptake in organic polymers at high pressures. J Phys E: Sci Instrum 17(6):483

Lundberg JL, Mooney EJ, Rogers CE (1969) Diffusion and solubility of methane in polyisobutylene. J Polym Sci A-2 Polym Phys 7(5):947–962. https://doi.org/10.1002/pol.1969.160070517

Brandrup J, Immergut EH, Grulke EA (eds) (1999) Polymer handbook, vol 1 & 2, 4th edn. Wiley, Hoboken

Lewis E, Duckett RA, Ward IM, Fairclough JPA, Ryan AJ (2003) The barrier properties of polyethylene terephthalate to mixtures of oxygen, carbon dioxide and nitrogen. Polymer 44(5):1631–1640. https://doi.org/10.1016/S0032-3861(02)00933-3

Areerat S, Hayata Y, Katsumoto R, Kegasawa T, Egami H, Ohshima M (2002) Solubility of carbon dioxide in polyethylene/titanium dioxide composite under high pressure and temperature. J Appl Polym Sci 86(2):282–288. https://doi.org/10.1002/app.10944

Tang Q, Yang B, Zhao Y, Zhao L (2007) Sorption and diffusion of sub/supercritical carbon dioxide in poly (methyl methacrylate). J Macromol Sci, Part B: Phys 46(2):275–284

Boyer SAE, Grolier J-PE, Yoshida H, Haudin J-M, Chenot J-L (2011) Thermodynamics and thermokinetics to model phase transitions of polymers over extended temperature and pressure ranges under various hydrostatic fluids. Thermodynamics-Interaction Studies-Solids, Liquids and Gases

Briscoe BJ, Zakaria S (1991) Interaction of CO2 gas with silicone elastomer at high ambient pressures. J Polym Sci B Polym Phys 29(8):989–999. https://doi.org/10.1002/polb.1991.090290809

Spyriouni T, Boulougouris GC, Theodorou DN (2009) Prediction of sorption of CO2 in glassy atactic polystyrene at elevated pressures through a new computational scheme. Macromolecules 42(5):1759–1769. https://doi.org/10.1021/ma8015294

Klotz IM (1963) Variation of solubility with depth in the ocean. A thermodynamic analysis. Limnol Oceangr 8(2):149–151. https://doi.org/10.4319/lo.1963.8.2.0149

Wiebe R, Gaddy VL (1939) The solubility in water of carbon dioxide at 50, 75 and 100°, at pressures to 700 atmospheres. J Am Chem Soc 61(2):315–318. https://doi.org/10.1021/ja01871a025

Wiebe R, Gaddy VL (1940) The solubility of carbon dioxide in water at various temperatures from 12 to 40° and at pressures to 500 atmospheres. Critical phenomena. J Am Chem Soc 62(4):815–817. https://doi.org/10.1021/ja01861a033

Sato Y, Takikawa T, Sorakubo A, Takishima S, Masuoka H, Imaizumi M (2000) Solubility and diffusion coefficient of carbon dioxide in biodegradable polymers. Ind Eng Chem Res 39(12):4813–4819. https://doi.org/10.1021/ie0001220

Tromans D (1998) Temperature and pressure dependent solubility of oxygen in water: a thermodynamic analysis. Hydrometallurgy 48(3):327–342

Briscoe BJ, Zakaria S (1990b) Polymer–gas interactions at high pressure: the use of ultrasonic probes. Polymer 31(3):440–447

Sato Y, Yurugi M, Fujiwara K, Takishima S, Masuoka H (1996) Solubilities of carbon dioxide and nitrogen in polystyrene under high temperature and pressure. Asian Thermophysical Prop Conf 125(1–2):129–138. https://doi.org/10.1016/S0378-3812(96)03094-4

Pino M, Duckett RA, Ward IM (2005) Single and mixed gas diffusion through polyethylene films. Polymer 46(13):4882–4890. https://doi.org/10.1016/j.polymer.2005.02.118

Jordan SM, Koros WJ (1990) Permeability of pure and mixed gases in silicone rubber at elevated pressures. J Polym Sci B Polym Phys 28(6):795–809. https://doi.org/10.1002/polb.1990.090280602

Briscoe BJ, Kelly CT (1996) The effect of structure on gas solubility and gas induced dilation in a series of poly(urethane) elastomers. Polymer 37(15):3405–3410. https://doi.org/10.1016/0032-3861(96)88488-6

Briscoe BJ, Zakaria S (1992) Sorption and dilation of silicone elastomer composites at high gas pressures: the role of interfacial quality. J Polym Sci B Polym Phys 30(9):959–969. https://doi.org/10.1002/polb.1992.090300904

Briscoe BJ, Savvas T, Kelly CT (1994) “Explosive decompression failure” of rubbers: a review of the origins of pneumatic stress induced rupture in elastomers. Rubber Chem Technol 67(3):384–416. https://doi.org/10.5254/1.3538683

Yamabe J, Nishimura S (eds) (2010) Estimation of critical pressure of decompression failure of EPDM composites for sealing under high-pressured hydrogen gas. Proceedings of the 18th European Conference on Fracture, CD–DOM. http://www.gruppofrattura.it/ocs/index.php/esis/ECF18/paper/view/6124/2002 Accessed 12 Oct 2017

Boyer SAE, Grolier J-PE (2005b) Simultaneous measurement of the concentration of a supercritical gas absorbed in a polymer and of the concomitant change in volume of the polymer. The coupled VW-pVT technique revisited. Polymer 46(11):3737–3747

Kazarian SG (2000) Polymer processing with supercritical fluids. Polymer. Science 42(1):78–101

Schrittesser B, Pinter G, Schwarz T, Kadar Z, Nagy T (2016) Rapid gas decompression performance of elastomers—a study of influencing testing parameters. Procedia Struct Integr 2:1746–1754. https://doi.org/10.1016/j.prostr.2016.06.220

Sato Y, Takikawa T, Takishima S, Masuoka H (2001) Solubilities and diffusion coefficients of carbon dioxide in poly(vinyl acetate) and polystyrene. J Supercrit Fluids 19(2):187–198. https://doi.org/10.1016/S0896-8446(00)00092-9

Nilsson F, Hallstensson K, Johansson K, Umar Z, Hedenqvist MS (2013) Predicting solubility and diffusivity of gases in polymers under high pressure: N2 in polycarbonate and poly(ether-ether-ketone). Ind Eng Chem Res 52(26):8655–8663. https://doi.org/10.1021/ie300975h

Chiou JS, Barlow JW, Paul DR (1985b) Polymer crystallization induced by sorption of CO2 gas. J Appl Polym Sci 30(9):3911–3924. https://doi.org/10.1002/app.1985.070300929

Klopffer M-H, Flaconnèche B (2001) Transport properties of gases in polymers. Bibliographic review. Oil Gas Sci Technol – Rev IFP Energ Nouvelles 56(3):223–244

Chiou JS, Barlow JW, Paul DR (1985a) Plasticization of glassy polymers by CO2. J Appl Polym Sci 30(6):2633–2642. https://doi.org/10.1002/app.1985.070300626

Bos A, Pünt IGM, Wessling M, Strathmann H (1999) CO2-induced plasticization phenomena in glassy polymers. J Membr Sci 155(1):67–78. https://doi.org/10.1016/S0376-7388(98)00299-3

Boyer SAE, Grolier J-PE (2005a) Modification of the glass transitions of polymers by high-pressure gas solubility. Pure Appl Chem 77(3):593–603

Wang W-CV, Kramer EJ, Sachse WH (1982) Effects of high-pressure CO2 on the glass transition temperature and mechanical properties of polystyrene. J Polym Sci Polym Phys Ed 20(8):1371–1384. https://doi.org/10.1002/pol.1982.180200804

Wessling M, Borneman Z, van den Boomgaard T, Smolders CA (1994) Carbon dioxide foaming of glassy polymers. J Appl Polym Sci 53(11):1497–1512. https://doi.org/10.1002/app.1994.070531112

Zhang Z, Handa YP (1998) An in-situ study of plasticization of polymers by high-pressure gases. J Polym Sci B Polym Phys 36(6):977–982

Chow TS (1980) Molecular interpretation of the glass transition temperature of polymer-diluent systems. Macromolecules 13(2):362–364. https://doi.org/10.1021/ma60074a029

Campion RP, Morgan GJ (1992) High pressure permeation and diffusion of gases in polymers of different structures. Plast Rubber Compos Process Appl 17(1):51–58

Paterson MS (1964) Effect of pressure on Young’s modulus and the glass transition in rubbers. J Appl Phys 35(1):176. https://doi.org/10.1063/1.1713063

Jones Parry E, Tabor D (1973) Effect of hydrostatic pressure on the mechanical properties of polymers. A brief review of published data. J Mater Sci 8(10):1510–1516. https://doi.org/10.1007/BF00551675

Crank J (1975) The mathematics of diffusion, vol 3, 2nd edn. Clarendon Press, Oxford

Arora KA, Lesser AJ, McCarthy TJ (1998) Preparation and characterization of microcellular polystyrene foams processed in supercritical carbon dioxide. Macromolecules 31(14):4614–4620. https://doi.org/10.1021/ma971811z

Naito Y, Kamiya Y, Terada K, Mizoguchi K, Wang J (1996) Pressure dependence of gas permeability in a rubbery polymer. J Appl Polym Sci 61(6):945–950

Lorge O, Briscoe BJ, Dang P (1999) Gas induced damage in poly (vinylidene fluoride) exposed to decompression. Polymer 40(11):2981–2991

Fleming GK, Koros WJ (1986) Dilation of polymers by sorption of carbon dioxide at elevated pressures. 1. Silicone rubber and unconditioned polycarbonate. Macromolecules 19(8):2285–2291. https://doi.org/10.1021/ma00162a030

Grandidier J-C, Baudet C, Boyer SA, Klopffer M-H, Cangémi L (2015) Diffuso-kinetics and diffuso-mechanics of carbon dioxide/polyvinylidene fluoride system under explosive gas decompression. Identification of key diffuso-elastic couplings by numerical and experimental confrontation. Oil Gas Sci. Technol. – Rev. IFP Energ Nouvelles 70(2):251–266. https://doi.org/10.2516/ogst/2013198

Ramsing N, Gundersen J (2000) Seawater and gases. Tabulated physical parameters of interest to people working with microsensors in marine systems, Denmark

Lubetkin SD (1994) Bubble nucleation and growth. In: Wedlock DJ (ed) Controlled particle, droplet and bubble formation. Butterworth-Heinemann Ltd, Oxford, pp 159–190

Arieli R, Marmur A (2011) Decompression sickness bubbles: are gas micronuclei formed on a flat hydrophobic surface? Respir Physiol Neurobiol 177(1):19–23. https://doi.org/10.1016/j.resp.2011.02.013

Arieli R, Marmur A (2013) Dynamics of gas micronuclei formed on a flat hydrophobic surface, the predecessors of decompression bubbles. Respir Physiol Neurobiol 185(3):647–652. https://doi.org/10.1016/j.resp.2012.11.020

Jones SF, Evans GM, Galvin KP (1999) Bubble nucleation from gas cavities—a review. Adv Colloid Interf Sci 80(1):27–50. https://doi.org/10.1016/S0001-8686(98)00074-8

Campbell J (1968) The tribonucleation of bubbles. J Phys D Appl Phys 1(8):1085

Wilt PM (1986) Nucleation rates and bubble stability in water–carbon dioxide solutions. J Colloid Interface Sci 112(2):530–538

Fischer S (2001) Blasenbildung von in Flüssigkeiten gelösten Gasen, Technische Universität München, Universitätsbibliothek

Papadopoulou V, Eckersley RJ, Balestra C, Karapantsios TD, Tang M-X (2013) A critical review of physiological bubble formation in hyperbaric decompression. Adv Colloid Interf Sci 191–192(0):22–30. https://doi.org/10.1016/j.cis.2013.02.002

Harvey EN, Barnes DK, McElroy WD, Whiteley AH, Pease DC, Cooper KW (1944) Bubble formation in animals. I. Physical factors. J Cell Comp Physiol 24(1):1–22. https://doi.org/10.1002/jcp.1030240102

Harvey EN (1945) Decompression sickness and bubble formation in blood and tissues. Bull N Y Acad Med 21(10):505

Boyer SAE, Gerland M, Castagnet S (2013) Gas environment effect on cavitation damage in stretched polyvinylidene fluoride. Polym Eng Sci 54(9):2139–2146. https://doi.org/10.1002/pen.23759

Hayward ATJ (1967) Tribonucleation of bubbles. Br J Appl Phys 18(5):641–644. https://doi.org/10.1088/0508-3443/18/5/314

Ikels KG (1970) Production of gas bubbles in fluids by tribonucleation. J Appl Physiol 28(4):524–527

Fraldi M, Cutolo A, Esposito L, Perrella G, Carbone, Maria Giovanna Pastore, Sansone L, Scherillo G, Mensitieri G (2014) Delamination onset and design criteria of multilayer flexible packaging under high pressure treatments. Innovative Food Sci Emerg Technol Doi: https://doi.org/10.1016/j.ifset.2014.02.016

Galotto MJ, Ulloa PA, Hernández D, Fernández-Martín F, Gavara R, Guarda A (2008) Mechanical and thermal behaviour of flexible food packaging polymeric films materials under high pressure/temperature treatments. Packag Technol Sci 21(5):297–308. https://doi.org/10.1002/pts.807

Baudet C, Grandidier J-C, Cangémi L (2011) A damage model for the blistering of polyvinylidene fluoride subjected to carbon dioxide decompression. J Mech Phys Solids 59(9):1909–1926. https://doi.org/10.1016/j.jmps.2011.04.010

Kane-Diallo O, Castagnet S, Nait-Ali A, Benoît G, Grandidier J-C (2016) Time-resolved statistics of cavity fields nucleated in a gas-exposed rubber under variable decompression conditions—support to a relevant modeling framework. Polym Test 51:122–130. https://doi.org/10.1016/j.polymertesting.2016.03.004

Dewimille B, Martin J, Jarrin J (1993) Behaviour of thermoplastic polymers during explosive decompressions in a petroleum environment. Le J Phys IV 3(C7):1559

Koga A, Uchida K, Yamabe J, Nishimura S (2011) Evaluation on high-pressure hydrogen decompression failure of rubber O-ring using design of experiments. International Journal of Automotive. Engineering 2(4):123–129

Van Liew HD, Burkard ME (1993) Density of decompression bubbles and competition for gas among bubbles, tissue, and blood. J Appl Physiol 75:2293

Ramesh NS, Rasmussen DH, Campbell GA (1991) Numerical and experimental studies of bubble growth during the microcellular foaming process. Polym Eng Sci 31(23):1657–1664. https://doi.org/10.1002/pen.760312305

Gent AN, Tompkins DA (1969) Nucleation and growth of gas bubbles in elastomers. J Appl Phys 40(6):2520–2525. https://doi.org/10.1063/1.1658026

Handa YP, Zhang Z (2000) A new technique for measuring retrograde vitrification in polymer–gas systems and for making ultramicrocellular foams from the retrograde phase. J Polym Sci B Polym Phys 38(5):716–725. https://doi.org/10.1002/(SICI)1099-0488(20000301)38:5<716:AID-POLB9>3.0.CO;2-N

Sheridan M, Shea L, Peters M, Mooney D (2000) Bioabsorbable polymer scaffolds for tissue engineering capable of sustained growth factor delivery. J Control Release 64(1–3):91–102. https://doi.org/10.1016/S0168-3659(99)00138-8

Kazarian SG, Vincent MF, Bright FV, Liotta CL, Eckert CA (1996) Specific intermolecular interaction of carbon dioxide with polymers. J Am Chem Soc 118(7):1729–1736. https://doi.org/10.1021/ja950416q

Chen X, Feng JJ, Bertelo CA (2006) Plasticization effects on bubble growth during polymer foaming. Polym Eng Sci 46(1):97–107. https://doi.org/10.1002/pen.20434

Jarrin J, Dewimille B, Devaux E (1994) Blistering of thermoplastic materials used in the petroleum industry. In: SPE Annual Technical Conference and Exhibition, New Orleans, p 203–214

Goldman S (2009) Generalizations of the Young–Laplace equation for the pressure of a mechanically stable gas bubble in a soft elastic material. J Chem Phys 131(18):184502. https://doi.org/10.1063/1.3259973

Goldman S (2010) Free energy wells for small gas bubbles in soft deformable materials. J Chem Phys 132(16):164509. https://doi.org/10.1063/1.3394940

Gaskins N, Vann RD, Hobbs GW, Swingle M, Lee S, Needham D (2001) Surface tension and bubble formation in agar gelatin. Undersea Hyperb Med Soc 28:56–59

Arieli Y, Katsenelson K, Arieli R (2007) Bubble reduction after decompression in the prawn Palaemon elegans by pretreatment with hyperbaric oxygen. Undersea Hyperb Med Soc 34(5):369–378

Jaravel J, Castagnet S, Grandidier J-C, Benoît G (2011) On key parameters influencing cavitation damage upon fast decompression in a hydrogen saturated elastomer. Polym Test 30(8):811–818. https://doi.org/10.1016/j.polymertesting.2011.08.003

Fradin JF, Le Bail A, Sanz PD, Molina-García AD (1998) Note. Behaviour of packaging materials during high pressure thawing. Food Sci Technol Int 4(6):419–424

Harris LD, Kim B-S, Mooney DJ (1998) Open pore biodegradable matrices formed with gas foaming. J Biomed Mater Res 42(3):396–402

Richter T (2014) Device and method for the high-pressure treatment of products (US8771773B2)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sterr, J., Fleckenstein, B.S. & Langowski, HC. The Theory of Decompression Failure in Polymers During the High-Pressure Processing of Food. Food Eng Rev 10, 14–33 (2018). https://doi.org/10.1007/s12393-017-9171-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-017-9171-9