Abstract

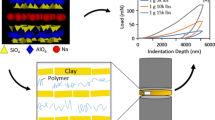

Fabricating composite films by dispersing clay in a polymer can provide functionalities such as antibiotic action and chemical adsorption. In this study, the effects of the shape and surface treatment of clay on the gas barrier properties, mechanical properties, thermal properties, and processing characteristics of polymer/clay composite films were investigated. Halloysites (HNTs) and vermiculites (VMTs), which are popular clays of the nanotube and nanoplate types, respectively, that are often employed to achieve functionality as they facilitate the carrying of chemicals, were incorporated into low-density polyethylene (LDPE). The effects of chemical treatment of the clay surface on the dispersibility of the clays in the polymer composites and on their properties were examined. Furthermore, the effects of the shapes and surface treatment of the clays on the drawabilities of the composite films, as well as the mechanical properties of the composite films according to the draw ratio were investigated. In the manufactured LDPE/clay composite films, the HNTs showed better dispersibility than the VMTs. After surface treatment with hydrochloric acid, the dispersibility improved relative to that before chemical treatment. With increasing clay content, the initial moduli of the composite sheets improved, but the tensile strengths and strains decreased. When VMTs were used, the gas barrier property of the composite film improved as the clay content increased; however, when HNTs were used, the gas barrier property decreased with increasing clay content When the clay surface was chemically treated, the drawabilities of the LDPE composites improved compared to those prior to surface treatment, and the drawabilities of the HNT composites were greater than those of the VMT composite. The maximum draw ratio of the surface-treated HNT composite film was the highest at 4.0, and the tensile strength increased by up to ≈3 times compared to that of the undrawn film. As the draw ratio increased, the gas barrier property, crystallinity, and the degree of orientation also increased.

Similar content being viewed by others

References

D. Pedrazzoli, A. Pegoretti, R. Thomann, J. Kristof, and J. Karger-Kocsis, Polym. Compos., 36, 869 (2015).

Y. Joo, Y. Jeon, S. U. Lee, J. H. Sim, J. Ryu, S. Lee, H. Lee, and D. Sohn, J. Phys. Chem. C, 116, 18230 (2012).

C. E. Tas, S. Hendessi, M. Baysal, S. Unal, F. C. Cebeci, Y. Z. Menceloglu, and H. Unal, Food Bioprocess Tech., 10, 789 (2017).

R. D. White, D. V. Bavykin, and F. C. Walsh, Nanotechnology, 23, 065705 (2012).

W. O. Yah, A. Takahara, and Y. M. Lvov, J. Am. Chem. Soc., 134, 1853 (2012).

S. Levis and P. Deasy, Int J. Pharm., 243, 125 (2002).

D. Tao, Y. Higaki, W. Ma, H. Wu, T. Shinohara, T. Yano, and A. Takahara, Polymer, 60, 284 (2015).

E. Horvath, J. Kristof, R. Frost, A. Redey, V. Vágvölgyi, and T. Cseh, J. Therm. Anal. Chem., 71, 707 (2003).

B. Lecouvet, M. Sclavons, S. Bourbigot, J. Devaux, and C. Bailly, Polymer, 52, 4284 (2011).

A-B. Zhang, L. Pan, H.-Y. Zhang, S.-T. Liu, Y. Ye, M.-S. Xia, and X-G. Chen, Colloids Surf. A: Physicochem. Eng. Asp, 396, 182 (2012).

S. Deng, J. Zhang, and L. Ye, Compos. Sci. Technol., 69, 2497 (2009).

V. P. Singh, K. Vimal, G. Kapur, S. Sharma, and V. Choudhary, J. Polym. Res, 23, 43 (2016).

Y. T. Park, Y. Qian, C. I. Lindsay, C. Nijs, R. E. Camargo, A. Stein, and C. W. Macosko, ACS Appl. Mater. Interfaces, 5, 3054 (2013).

S. Tjong and Y. Meng, J. Polym. Sci. B: Polym. Phys, 41, 1476 (2003).

Y. Qian, W. Liu, Y. T. Park, C. I. Lindsay, R. Camargo, C. W. Macosko, and A. Stein, Polymer, 53, 5060 (2012).

H. S. Lee and J. H. Chang, J. Korean Ceram. Soc., 55, 85 (2018).

L. Pérez-Maqueda, O. Caneo, J. Poyato, and J. Pérez-Rodríguez, Phys. Chem. Miner, 28, 61 (2001).

S. Tjong, Y. Meng, and A. Hay, Chem. Mater, 14, 44 (2002).

P. G. Slade and W. P. Gates, Appl Clay Sci., 25, 93 (2004).

K. Pramoda, T. Liu, Z. Liu, C. He, and H.-J. Sue, Polym. Degrad. Stab., 81, 47 (2003).

Y. Zheng, Y. Zheng, and R. Ning, Mater. Lett., 57, 2940 (2003).

K. Magniez, B. L. Fox, and M. G. Looney, Polym Eng. Sci., 52, 1402 (2012).

C. F. On, J. Polym. Sci. B: Polym. Phys., 41, 2902 (2003).

M. Du, B. Guo, M. Liu, and D. Jia, Polym. J., 38, 1198 (2006).

E. P. Giannelis, Appl. Organomet Chem., 12, 675 (1998).

K. Goren, L. Chen, L. S. Schadler, and R. Ozisik, J. Supercritical Fluids, 51, 420 (2010).

G. Wang, X. Y. Chen, R. Huang, and L. Zhang, J. Mater. Sci. Lett, 21, 985 (2002).

A. K. Panda, B. G. Mishra, D. K. Mishra, and R. K. Singh, Colloid Surf. A: Physicochem. Eng. Asp., 363, 98 (2010).

C. Belver, M. A. Bañares Muñoz, and M. A. Vicente, Chem. Mater, 14, 2033 (2002).

K. Belkassa, F. Bessaha, K. Marouf-Khelifa, I. Batonneau-Gener, J.-D. Comparot, and A. Khelifa, Colloid Surf. A: Physicochem. Eng.Asp., 421, 26 (2013).

J. Ravichandran and B. Sivasankar, Clays Clay Miner., 45, 854 (1997).

M. Topouzi, E. Kontonasaki, D. Bikiaris, L. Papadopoulou, K. M. Paraskevopoulos, and P. Koidis, J. Mech. Behav. Biomed. Mater, 69, 213 (2017).

S.-Y. Fu, X-Q. Feng, B. Lauke, and Y.-W. Mai, Compos. Part B: Eng., 39, 933 (2008).

U. A. Handge, K. Hedicke-Höchstötter, and V. Altstädt, Polymer, 51, 2690 (2010).

K. Hedicke-Höchst:otter, G. T. Lim, and V. Altstadt, Compos. Sci. Technol., 69, 330 (2009).

H. Ismail, P. Pasbakhsh, M. A. Fauzi, and A. A. Bakar, Polym. Test, 27, 841 (2008).

J. H. Chang, Y. U. An, and G. S. Sur, J. Polym. Sci. Part B: Polym. Phys, 41, 94 (2003).

D. Wu, L. Wu, L. Wu, and M. Zhang, Polym. Degrad. Stab., 91, 3149 (2006).

X. Yang, Y. Zhang, Y. Xu, S. Gao, and S. Guo, Macromol. Res, 25, 270 (2017).

Q. Zhang, D. Li, D. Lai, and B. Ou, Macromol. Res., 23, 802 (2015).

M. Du, B. Guo, and D. Jia, Eur. Polym. J., 42, 1362 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Acknowledgments: This work was supported by the Technology Innovation Program (No. 10063291) funded by Ministry of Trade, Industry & Energy (MOTIE, Korea).

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Youm, J.S., Ban, H.R., Chang, J.H. et al. Effects of the Shape and Surface Treatment of Clay on the Process of Uniaxially Drawn Low-Density Polyethylene/Clay Composites Films. Macromol. Res. 28, 356–364 (2020). https://doi.org/10.1007/s13233-020-8048-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-020-8048-6