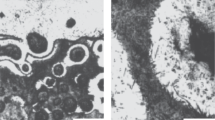

The production, structurization, and resultant properties of metal matrix ‘iron–carbon alloy–granular hardmetal reinforcement’ materials are studied. The vacuum suction method ensures almost complete filling of interparticle voids with molten metals and results in composites containing hardmetal reinforcement with 0.17–0.7 mm particles. The composites show the microstructure that has no pronounced transition zone at the hardmetal–metal interface and has a ‘granular’ austenitic cast iron matrix and a significant amount of lamellar graphite. The mechanical properties and abrasive impact wear resistance of the white cast iron and carbon steel materials are examined. The optimum combination of properties is exhibited by the composite consisting of steel 45 and 60 vol.% KKhNF15 hardmetal.

Similar content being viewed by others

References

V.A. Maslyuk, “Tungsten-free hardmetals and carbide steels with chromium carbides,” Powder Metall. Met. Ceram., 53, No. 3–4, 162–169 (2014).

V.K. Vitryanyuk and A.N. Stepanchuk, Sintered Tungstenless Hardmetals [in Russian], ZAO Vipol, Kyiv (2011), p. 248.

A.M. Verkhovlyuk, Interaction of Liquid and Solid Phases in Metallurgical Processes [in Russian], Naukova Dumka, Kyiv (2014), p. 168.

A.A. Vostryakov, “Kinetics of interaction between chromium, vanadium, and titanium carbides and iron–carbon alloys,” Dep. VINITI, No. 2, 75–83 (1980).

A.M. Verkhovlyuk, “Semiautomatic unit for studying the dissolution kinetics,” Adgez. Raspl. Paika Mater., No. 27, 64–67 (1982).

B.M. Lepinski and A.A. Vostryakov, Dissolution of Solid Phases in Metallic Melts [in Russian], Nauka, Moscow (1978), p. 147.

P.M. Shurygin and V.D. Shantarin, “Dissolution of metals in iron–carbon alloys,” Izv. Vuz. Chern. Metall., No. 10, 5–11 (1963).

T.A. Terekhina, S.Ya. Pirogov, V.F. Sokolov, et al., “Reactions of some refractory compounds with a Ni–Cr–Si–B melt,” Powder Metall. Met. Ceram., 19, No. 8, 558–562 (1980).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 58, Nos. 7–8 (528), pp. 78–87, 2019.

Rights and permissions

About this article

Cite this article

Maslyuk, V.A., Karaimchuk, E.S., Alekseev, V.I. et al. Production, Structurization, and Properties of Wear-Resistant ‘Iron–Carbon Alloy–Granular Hardmetal Reinforcement’ Materials. Powder Metall Met Ceram 58, 431–438 (2019). https://doi.org/10.1007/s11106-019-00092-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-019-00092-x