Abstract

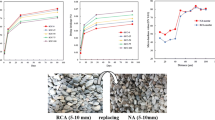

Many researchers believe that the adhesion failure between rubber and cement paste is one of the main reasons the strength of concrete containing these aggregates drops sharply. This paper provides strength and durability experiment results which reveal the effect of pre-coating rubber granules with crushed dune sand in terms of their mechanical performance, these tests aimed to enhance the durability properties of self-compacting concretes (SCC) transfer properties and structure. Results show that mechanical properties of SCC made with treated rubber granules are improved compared with concrete mix made with the untreated rubber. Natural sand is replaced with 2.5% of rubber granules pre-coating with (0–20%) of crushed dune sand as partial replacement of cement. The compressive strength of SCC rises with the proportionate increase of the crushed dune sand percentage. This could confirm the strengthening of the transition zone (between cement paste and rubber aggregate) by introducing siliceous additions with high fineness.

Similar content being viewed by others

References

Trouzine H, Asroun A, Asroun N, Belabdelouhab F, Long NT (2011) Problématique des pneumatiques usagés en Algérie. Nat Technol 5:28–35

Monalisa Behera SK, Bhattacharyya AK, Minocha R, Deoliya S Maiti (2014) Recycled aggregate from C&D waste and its use in concrete—a breakthrough towards sustainability in construction sector: a review. Constr Build Mater 68:501–516

Zaoiai S, Makani A, Tafraoui A, Benmerioul F (2016) Optimization and mechanical characterization of self-compacting concrete incorporating rubber aggregates. Asian J Civil Eng (BHRC) 17:817–829

Benmerioul F, Makani A, Tafraoui A, Zaoiai S (2017) Valorization of the crushed dune sand in the formulation of self-compacting concrete. Proc Eng 171:672–678

Segre N, Joekes I (2000) Use of tire rubber particles as addition to cement paste. Cem Concr Res 30:1421–1425

Cairns R, Kew H, Kenny M. (2004) The use of recycled rubber tyres in concrete construction. Final report. The Onyx Environmental Trust, University of Strathclyde, Glasgow

Dong Qiao, Huang Baoshan, Shu Xiang (2013) Rubber modified concrete improved by chemically active coating and silane coupling agent. Constr Build Mater 48:116–123

Li G, Wang Z, Leung CK, Tang S, Pan J, Huang W, Chen E (2016) Properties of rubberized concrete modified by using silane coupling agent and carboxylated SBR. J Clean Prod 112:797–807

Pelisser F, Zavarise N, Longo TA, Bernardin AM (2011) Concrete made with recycled tire rubber: effect of alkaline activation and silica fume addition. J Clean Prod 19:757–763

Gupta T, Chaudhary S, Sharma RK (2015) Impact resistance of concrete containing waste rubber fiber and silica fume. Int J Impact Eng 83:76–87

Ahmed T, Escadeillas G, Lebaili S, Vidal T (2009) Metakaolin in the formulation of UHPC. Constr Build Mater 23:669–674

Ahmed T, Escadeillas G, Vidal T (2016) Durability of the ultra high performances concrete containing métakaolin. Constr Build Mater 112:980–987

Güneyisi E, Gesoglu M, Öztturan T (2004) Properties of rubber rized concretes containing silica fume. Cement Concrete Res 34:2309–2317

Meddah A, Beddar M, Bali A (2014) Use of shredded rubber tire aggregates for roller compacted concrete pavement. J Clean Prod 72:187–192

Onuaguluchi O, Panesar DK (2014) Hardened properties of concrete mixtures containing pre-coated crumb rubber and silica fume. J Clean Prod 82:125–131

AFGC Association Française du Génie Civil (2013) LesBAP. Recommandations provisoires. p 63

NF EN 12350-8, Novembre 2010 Partie 8: autoplaçants—essai d’étalement au cône

NF EN 12350-10, Novembre 2010 Partie Béton autoplaçant—essai à la boite en L

NF EN 12350-11, Novembre 2010 Partie 11: Béton autoplaçant—essai de stabilité au Tamis

Guettala S, Mezghiche B (2011) Compressive strength and hydration with age of cement pastes containing dune sand powder. Constr Build Mater 25:1263–1269

Gesoglut M (2012) Fresh and hardened characteristics of self-compacting concretes made with combined use of marble powder, limestone filler, and fly ash. Constr Build Mater 37:160–170

Alawad OA, Alhozaimy A, Jaafar MS, Al-Negheimish A, Aziz FNA (2014) Microstructure analyses of autoclaved ground dune sand—Portland cements paste. Constr Build Mater 65:14–19

Huang C-Y, Feldman RF (1985) Hydration reactions in Portland cement silica fume blends. Cement Concr Res 15(4):585–592

Goldman A, Bentur A (1989) Bond effects in high silica-fume. ACI J Mater 86:440

Wang Y, Ye G (2010) Influence on microstructure of micronized sand as cement replacement in cementations materials. J Wuhan Univ Technol 32(17):152–157

Bédérina M, Khenfer MM, Dheilly RM, Quéneudec M (2005) Reuse of local sand: effect of limestone filler proportion on the rheological and mechanical properties of different sand concretes. Cem Concr Res 35:1172–1179

Xue J, Shinozuka M (2013) Rubberized concrete: a green structural material with enhanced energy-dissipation capability. Constr Build Mater 42:196–204

Pacheco-Torgal F, Ding Y, Jalali S (2012) Properties and durability of concrete containing polymeric wastes (tyre rubber and polyethylene terephthalate bottles): an overview. Constr Build Mater 30:714–724

Onuaguluchi O (2015) Effects of surface pre-coating and silica fume on crumb rubber-cement matrix interface and cement mortar properties. J Clean Prod 104:339–345

Guneyisi E, Gesoglu M, Booya E, Mermerdas K (2015) Strength and permeability properties of self-compacting concrete with cold bonded fly ash lightweight aggregate. Constr Build Mater 74:17–24

Zimbelmann R (1985) A contribution of the problem of cement-aggregate bond. Cem Concr Res 15:801–808

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zaouai, S., Tafraoui, A., Makani, A. et al. Hardened and transfer properties of self-compacting concretes containing pre-coated rubber aggregates with crushed dune sand. J Rubber Res 23, 5–12 (2020). https://doi.org/10.1007/s42464-019-00030-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-019-00030-x