Abstract

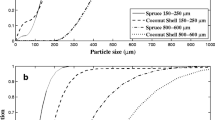

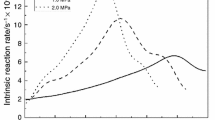

Gasification of the char obtained from the spent substrate after mushroom cultivation was carried out in a thermobalance connected to a mass spectrometer in the temperature range from 200 to 950 °C and CO2 concentration from 5 to 100 vol%. Under non-isothermal conditions, in addition to the char gasification process, both carbonation and calcination reactions occurred. The investigation of gasification kinetics in CO2 was carried out under isothermal conditions. The rate of gasification reaction was determined from the shrinking core model, and kinetic constant has been calculated from Langmuir–Hinshelwood kinetics. On the basis of the conducted research, it was observed that the saturation of active sites on the char particles occurred above 50 vol% CO2, regardless of temperature. The analysis of gas composition indicates CO as the main product of gasification.

Similar content being viewed by others

References

Dong J, Nzihou A, Chi Y, Weiss-Hortala E, Ni M, Lyczko N, et al. Hydrogen-rich gas production from steam gasification of bio-char in the presence of CaO. Waste Biomass Valoriz. 2017;8:2735–46.

McKendry P. Energy production from biomass (part 1): overview of biomass. Bioresour Technol. 2002;83:37–46.

Zhong C, Wei X. A comparative experimental study on the liquefaction of wood. Energy. 2004;29:1731–41.

Bridgwater AV, Toft AJ, Brammer JG. A techno-economic comparison of power production by biomass fast pyrolysis with gasification and combustion. Renew Sustain Energy Rev. 2002;6:181–248.

Wang G, Zhang J, Shao J, Liu Z, Wang H, Li X, et al. Experimental and modeling studies on CO2 gasification of biomass chars. Energy. 2016;114:143–54.

McKendry P. Energy production from biomass (part 3): gasification technologies. Bioresour Technol. 2002;83:55–63.

Mahinpey N, Gomez A. Review of gasification fundamentals and new findings: reactors, feedstock, and kinetic studies. Chem Eng Sci. 2016;148:14–31.

Chmielniak T, Sobolewski A, Tomaszewicz G. CO2-enhanced coal gasification. Experience of the institute for chemical processing of coal. Przem Chem. 2015;94:442–8.

Roberts DG, Harris DJ. Char gasification with O2, CO2, and H2O: effects of pressure on intrinsic reaction kinetics. Energy Fuels. 2000;14:483–9.

Farid MM, Jeong HJ, Hwang J. Co-gasification of coal-biomass blended char with CO2 and H2O: effect of partial pressure of the gasifying agent on reaction kinetics. Fuel. 2015;162:234–8.

Lyons GA, Sharma HSS, Kilpatrick M, Cheung L, Moore S. Monitoring of changes in substrate characteristics during mushroom compost production. J Agric Food Chem. 2006;54:4658–67.

Finney KN, Ryu C, Sharifi VN, Swithenbank J. The reuse of spent mushroom compost and coal tailings for energy recovery: comparison of thermal treatment technologies. Bioresour Technol. 2009;100:310–5.

Porada S, Czerski G, Grzywacz P, Makowska D, Dziok T. Comparison of the gasification of coals and their chars with CO2 based on the formation kinetics of gaseous products. Thermochim Acta. 2017;653:97–105.

Qin Y. Catalytic effect of alkali metal in biomass ash on the gasification of coal char in CO2. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08719-2.

Di Blasi C. Combustion and gasification rates of lignocellulosic chars. Prog Energy Combust Sci. 2009;35:121–40.

Wang Y, Bell DA. Competition between H2O and CO2 during the gasification of Powder River Basin coal. Fuel. 2017;187:94–102.

Williams BC, McMullan JT, McCahey S. An initial assessment of spent mushroom compost as a potential energy feedstock. Bioresour Technol. 2001;79:227–30.

Ma Y, Wang Q, Sun X, Wang X, Su W, Song N. A study on recycling of spent mushroom substrate to prepare chars and activated carbon. BioResources. 2014;9:3939–54.

Jiang H, Cheng Z, Zhao T, Liu M, Zhang M, Li J, et al. Pyrolysis kinetics of spent lark mushroom substrate and characterization of bio-oil obtained from the substrate. Energy Convers Manag. 2014;88:259–66.

Niedzielski P, Mleczek M, Budka A, Rzymski P, Siwulski M, Jasińska A, et al. A screening study of elemental composition in 12 marketable mushroom species accessible in Poland. Eur Food Res Technol. 2017;243:1759–71.

Liu Z, Wang Q. Calculation and confirmation of the kinetic triplet of metallurgical coke gasification with carbon dioxide under isothermal conditions. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08660-4.

Ollero P, Serrera A, Arjona R, Alcantarilla S. The CO2 gasification kinetics of olive residue. Biomass Bioenergy. 2002;24:151–61.

Bojan J, Nebojsa M, Dragoslava S. The gaseous products characterization of the pyrolysis process of various agricultural residues using TGA–DSC–MS techniques. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08733-4.

Pacioni TR, Soares D, Di Domenico M, Rosa MF, de Fátima Peralta Muniz Moreira R, José HJ. Bio-syngas production from agro-industrial biomass residues by steam gasification. Waste Manag. 2016;58:221–9.

Dupont C, Nocquet T, Da Costa JA, Verne-Tournon C. Kinetic modelling of steam gasification of various woody biomass chars: influence of inorganic elements. Bioresour Technol. 2011;102:9743–8.

Nowicki L, Ledakowicz S. Comprehensive characterization of thermal decomposition of sewage sludge by TG-MS. J Anal Appl Pyrol. 2014;110:220–8.

APHA. Standard methods for the examination of water and wastewater. 21st ed. Washington, DC: American Public Health Association; 2005.

Nowicki L, Antecka A, Bedyk T, Stolarek P, Ledakowicz S. The kinetics of gasification of char derived from sewage sludge. J Therm Anal Calorim. 2011;104:693–700.

Baker EH. The calcium oxide-carbon dioxide system in the pressure range 1–300 atmospheres. J Chem Soc. 1962. https://doi.org/10.1039/jr9620000464.

Ahmed II, Gupta AK. Kinetics of woodchips char gasification with steam and carbon dioxide. Appl Energy. 2011;88:1613–9.

Nowicki L, Markowski M. Gasification of pyrolysis chars from sewage sludge. Fuel. 2015;143:476–83.

Evans J, Szekely JW. A structural model for gas–solid reactions with a moving boundary. Chem Eng Sci. 1970;25:1091–107.

Ishida M, Wen CY. Comparison of zone-reaction model and unreacted-core shrnking model in solid–gas reactions-I isothermal analysis. Chem Eng Sci. 1971;26:1031–41.

Bhatia SK, Perlmutter DD. A random pore model for fluid–solid reoctions: l. Isothermal, kinetic control. AIChE J. 1980;26:379–86.

Liu Z, Wang Q. Kinetic study on metallurgical coke gasification by steam under various pressures. J Therm Anal Calorim. 2017;129:1839–45.

Barrio M, Hustad JE. CO2 gasification of birch char and the effect of CO inhibition on the calculation of chemical kinetics. In: Bridgewater AV, editor. Progress in thermochemical biomass conversion, vol. 1. Oxford: Blackwell Science; 2001. pp. 47–60.

Dhyani V, Kumar J, Bhaskar T. Thermal decomposition kinetics of sorghum straw via thermogravimetric analysis. Bioresour Technol. 2017;245:1122–9. https://doi.org/10.1016/j.biortech.2017.08.189.

Acknowledgements

This study was performed in the frame of project: Research centre for low-carbon energy technologies, Project No. CZ.02.1.01/0.0/0.0/16_019/0000753.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Slezak, R., Krzystek, L. & Ledakowicz, S. CO2 gasification of char from spent mushroom substrate in TG-MS system. J Therm Anal Calorim 140, 2337–2345 (2020). https://doi.org/10.1007/s10973-019-09024-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-09024-8