Abstract

In liquid-liquid segmented flow slug size determines the interfacial area as well as the intensity of Taylor vortices and is thus an important operational parameter, decisive for mass transfer performance of biphasic micro-reactors and -extractors. Resulting slug sizes conventionally depend on material properties, flow and geometric parameters of the mixing point of the liquids. To evade tedious material specific design of the mixing point, modular devices, which allow active adjustment of developing slug sizes, are desirable. Such a slug generator is presented in this study. By altering the mixing point geometry during operation, it allows continuous manipulation of the slug formation process and thus slug size. The slug generation process in this device is investigated experimentally and with help of CFD simulations in order to identify its geometric influences. The findings lead to an optimized device design, whose capability to generate slugs of adjustable size and with low dispersity is demonstrated experimentally.

Graphical Abstract

Similar content being viewed by others

References

Ghaini A, Kashid MN, Agar DW (2010) Effective interfacial area for mass transfer in the liquid–liquid slug flow capillary microreactors. Chem Eng Process Process Intensif 49(4):358–366. https://doi.org/10.1016/j.cep.2010.03.009

Kashid MN, Gerlach I, Goetz S et al (2005) Internal circulation within the liquid slugs of a liquid−liquid slug-flow capillary microreactor. Ind Eng Chem Res 44(14):5003–5010. https://doi.org/10.1021/ie0490536

Abiev RS, Lavretsov IV (2012) Intensification of mass transfer from liquid to capillary wall by Taylor vortices in minichannels, bubble velocity and pressure drop. Chem Eng Sci 74:59–68. https://doi.org/10.1016/j.ces.2012.02.024

Arsenjuk L, Kaske F, Franzke J et al (2016) Experimental investigation of wall film renewal in liquid–liquid slug flow. Int J Multiphase Flow 85:177–185. https://doi.org/10.1016/j.ijmultiphaseflow.2016.06.009

Pan Z, Zhang X, Xie Y et al (2014) Instantaneous mass transfer under gas-liquid Taylor flow in circular capillaries. Chem Eng Technol 37(3):495–504. https://doi.org/10.1002/ceat.201300354

Bercic G, Pintar A (1997) The role of gas bubbles and liquid slug lengths on mass transport in the Taylor flow through capillaries. Chem Eng Sci 52(21–22):3709–3719. https://doi.org/10.1016/S0009-2509(97)00217-0

Ufer A, Mendorf M, Ghaini A et al (2011) Liquid/liquid slug flow capillary microreactor. Chem Eng Technol 34(3):353–360. https://doi.org/10.1002/ceat.201000334

Dittmar I, Ehrhard P (2011) Numerical study of liquid/liquid slug flow in a capillary microreactor. Proc Appl Math Mech 11(1):617–618. https://doi.org/10.1002/pamm.201110298

Ghaini A, Mescher A, Agar DW (2011) Hydrodynamic studies of liquid–liquid slug flows in circular microchannels. Chem Eng Sci 66(6):1168–1178. https://doi.org/10.1016/j.ces.2010.12.033

Abiev RS (2013) Bubbles velocity, Taylor circulation rate and mass transfer model for slug flow in milli- and microchannels. Chem Eng J 227:66–79. https://doi.org/10.1016/j.cej.2012.10.009

Zhu P, Wang L (2016) Passive and active droplet generation with microfluidics: a review. Lab Chip 17(1):34–75. https://doi.org/10.1039/c6lc01018k

de Menech M, Garstecki P, Jousse F et al (2008) Transition from squeezing to dripping in a microfluidic T-shaped junction. J Fluid Mech 595:141–161. https://doi.org/10.1017/S002211200700910X

Garstecki P, Fuerstman MJ, Stone HA et al (2006) Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up. Lab Chip 6(3):437–446. https://doi.org/10.1039/b510841a

Chen JM, Kuo M-C, Liu C-P (2011) Control of droplet generation in flow-focusing microfluidic device with a converging-diverging nozzle-shaped section. Jpn J Appl Phys 50(10):107301. https://doi.org/10.1143/JJAP.50.107301

van Steijn V, Kreutzer MT, Kleijn CR (2007) μ -PIV study of the formation of segmented flow in microfluidic T-junctions. Chem Eng Sci 62(24):7505–7514. https://doi.org/10.1016/j.ces.2007.08.068

Xu JH, Li SW, Tan J et al (2008) Correlations of droplet formation in T-junction microfluidic devices: from squeezing to dripping. Microfluid Nanofluid 5(6):711–717. https://doi.org/10.1007/s10404-008-0306-4

Gupta A, Kumar R (2010) Effect of geometry on droplet formation in the squeezing regime in a microfluidic T-junction. Microfluid Nanofluid 8(6):799–812. https://doi.org/10.1007/s10404-009-0513-7

Fu T, Funfschilling D, Ma Y et al (2010) Scaling the formation of slug bubbles in microfluidic flow-focusing devices. Microfluid Nanofluid 8(4):467–475. https://doi.org/10.1007/s10404-009-0471-0

Zeng W, Li S, Wang Z (2015) Closed-loop feedback control of droplet formation in a T-junction microdroplet generator. Sensors Actuators A Phys 233:542–547. https://doi.org/10.1016/j.sna.2015.08.002

Miller E, Rotea M, Rothstein JP (2010) Microfluidic device incorporating closed loop feedback control for uniform and tunable production of micro-droplets. Lab Chip 10(10):1293–1301. https://doi.org/10.1039/b925497h

Chong ZZ, Tan SH, Gañán-Calvo AM et al (2016) Active droplet generation in microfluidics. Lab Chip 16(1):35–58. https://doi.org/10.1039/c5lc01012h

Mac Giolla Eain M, Egan V, Punch J (2013) Film thickness measurements in liquid–liquid slug flow regimes. Int J Heat Fluid Flow 44:515–523. https://doi.org/10.1016/j.ijheatfluidflow.2013.08.009

Subramanian B, Kim N, Lee W et al (2011) Surface modification of droplet polymeric microfluidic devices for the stable and continuous generation of aqueous droplets. Langmuir 27(12):7949–7957. https://doi.org/10.1021/la200298n

Brackbill JU, Kothe DB, Zemach C (1992) A continuum method for modeling surface tension. J Comput Phys 100(2):335–354. https://doi.org/10.1016/0021-9991(92)90240-y

ANSYS Inc. (2013) ANSYS Fluent Theory Guide, Release 15.0, 275 Technology Drive Canonsburg, PA 15317

Wörner M (2012) Numerical modeling of multiphase flows in microfluidics and micro process engineering: a review of methods and applications. Microfluid Nanofluid 12(6):841–886. https://doi.org/10.1007/s10404-012-0940-8

Umbanhowar PB, Prasad V, Weitz DA (2000) Monodisperse emulsion generation via drop break off in a coflowing stream. Langmuir 16(2):347–351. https://doi.org/10.1021/la990101e

Chen X, Glawdel T, Cui N et al (2015) Model of droplet generation in flow focusing generators operating in the squeezing regime. Microfluid Nanofluid 18(5–6):1341–1353. https://doi.org/10.1007/s10404-014-1533-5

Acknowledgements

The authors thank the Intelligent Microsystems Institute of TU Dortmund University, especially M.Sc. Philipp Czyba and Dipl.-Ing. Ulrich Marggraf, who kindly shared their facilities and knowledge in oxygen plasma treatment to hydrophobically modify the devices.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Article Highlights

– Slug formation can be manipulated by adjusting the geometry of the liquid mixing point.

– For geometric control of slug size, majority of slug volume should be formed in squeezing mechanism during growth phase.

– A simple algebraic model is derived, which allows prediction of slug size with a maximum deviation of 20%.

Appendix

Appendix

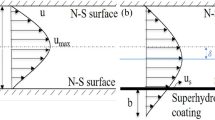

Simplified model to predict slug length by geometric considerations

Determination of volume contribution of growth stage

Similar triangles ∆ABC~∆ADE

for clear arrangement introducing

Volume contribution of growth stage

Determination of the duration of the detachment process

Experimentally determined correlation

Volume contribution of detachment stage

Calculation of slug length

Slug lengths assuming a cylindrical shape with spherical caps and ignoring wall film

Rights and permissions

About this article

Cite this article

Arsenjuk, L., Asshoff, M., Kleinheider, J. et al. A device for continuous and flexible adjustment of liquid-liquid slug size in micro-channels. J Flow Chem 10, 409–422 (2020). https://doi.org/10.1007/s41981-019-00064-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41981-019-00064-7