Abstract

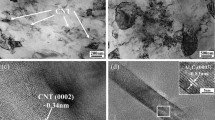

Multilayered Al/Ni energetic structural materials integrating exothermic properties and mechanical properties were prepared by the method of electrodeposition and hot pressing in this research. Then, the uniaxial quasi-static compression and split Hopkinson pressure bar experiments were conducted at strain rates from 10−4 to 6.5 × 103 s−1 at room temperature. The effects of compression strain rate on the microstructure evolution and the compressive properties of multilayered Al/Ni energetic structural materials were systematically investigated. With increasing quasi-static compression strain rate, the compression strength increased slightly for two kinds of Al/Ni multilayers prepared under different hot pressing time. With the hot pressing process extending to 4 h, the dynamic compression strength of multilayered Al/Ni composites monotonically increased from 494.7 to 564.2 MPa with increasing strain rate. It was shown that Al/Ni energetic structural materials exhibited evident strain hardening and strain rate strengthening. However, when the compression strain rate reached 6500 s−1, the Al/Ni composite prepared with the hot pressing time of 1 h showed prominent thermal softening. Notwithstanding, it was found that the compression strength of Al/Ni composite prepared at 4 h was evidently higher than that at 1 h, since the second phase reinforcement counteracted the thermal softening. In addition, the critical failure strain presented obviously increasing tendency with the increased compression strain rates.

Similar content being viewed by others

References

L. Wang, J. Liu, S. Li, and X. Zhang, Investigation on Reaction Energy, Mechanical Behavior and Impact Insensitivity of W-PTFE-Al Composites with Different W Percentage, Mater. Des., 2016, 92, p 397–404

R.V. Reeves, A.S. Mukasyan, and S.F. Son, Thermal and Impact Reaction Initiation in Ni/Al Heterogeneous Reactive Systems, J. Phys. Chem. C, 2010, 114(35), p 14772–14780

L. Qiao, X.F. Zhang, Y. He, X.N. Zhao, and Z.W. Guan, Multiscale Modelling on the Shock-Induced Chemical Reactions of Multifunctional Energetic Structural Materials, J. Appl. Phys., 2013, 113(17), p 173513

X.F. Zhang, J. Zhang, L. Qiao, A.S. Shi, Y.G. Zhang, Y. He, and Z.W. Guan, Experimental Study of the Compression Properties of Al/W/PTFE Granular Composites under Elevated Strain Rates, Mater. Sci. Eng., A, 2013, 581(10), p 48–55

H. Ren, X. Liu, and J. Ning, Impact-Initiated Behavior and Reaction Mechanism of W/Zr Composites with SHPB Setup, AIP Adv., 2016, 6(11), p 115205

Q. Wu, Q.M. Zhang, R.R. Long, K. Zhang, and J. Guo, Potential Space Debris Shield Structure Using Impact-Initiated Energetic Materials Composed of Polytetrafluoroethylene and Aluminum, Appl. Phys. Lett., 2016, 108(10), p 101903

D.B. Nielson, B.N. Ashcroft, and D.W. Doll, Reactive Material Compositions and Projectiles Containing Same, U. S. Patent No. 8568541, 2013

G.D. Hugus, E.W. Sheridan, and G.W. Brooks, Structural Metallic Binders for Reactive Fragmentation Weapons, U.S. Patent No. 8250985, 2012

P. Church, R. Claridge, P. Ottley, I. Lewtas, N. Harrison, P. Gould, C. Braithwaite, and D. Williamson, Investigation of a Nickel–Aluminum Reactive Shaped Charge Liner, J. Appl. Mech., 2013, 80, p 031701

C.T. Wei, E. Vitali, F. Jiang, S.W. Du, D.J. Benson, K.S. Vecchio, N.N. Thadhani, and M.A. Meyers, Quasi-Static and Dynamic Response of Explosively Consolidated Metal–Aluminum Powder Mixtures, Acta Mater., 2012, 60(3), p 1418–1432

H. Zhao, C. Tan, X. Yu, X. Ning, Z. Nie, H. Cai, F. Wang, and Y. Cui, Enhanced Reactivity of Ni-Al Reactive Material Formed by Cold Spraying Combined with Cold-Pack Rolling, J. Alloys Compd., 2018, 741, p 883–894

S.W. Kuk, J. Yu, and H.J. Ryu, Stationary Self-propagation Combustion with Variations in the Total Layer Thickness of Compression-Bonded Ni-Sputtered Al Foil Multilayers, J. Alloys Compd., 2015, 626, p 16–19

W. Xiong, X. Zhang, Y. Wu, Y. He, C. Wang, and L. Guo, Influence of Additives on Microstructures, Mechanical Properties and Shock-Induced Reaction Characteristics of Al/Ni Composites, J. Alloys Compd., 2015, 648, p 540–549

S. Simoes, A.S. Ramos, F. Viana, O. Emadinia, M.T. Vieira, and M.F. Vieira, Ni/Al Multilayers Produced by Accumulative Roll Bonding and Sputtering, J. Mater. Eng. Perform., 2016, 25(10), p 4394–4401

C. Ji, Y. He, C.T. Wang, Y. He, X. Pan, J. Jiao, and L. Guo, Investigation on Shock-Induced Reaction Characteristics of an Al/Ni Composite Processed via Accumulative Roll-Bonding, Mater. Des., 2017, 116, p 591–598

L. Battezzati, C. Antonione, and F. Fracchia, Ni-Al Intermetallics Produced by Cold-Rolling Elemental Sheets, Intermetallics, 1995, 3(1), p 67–71

A. Mozaffari, H.D. Manesh, and K. Janghorban, Evaluation of Mechanical Properties and Structure of Multilayered Al/Ni Composites Produced by Accumulative Roll Bonding (ARB) Process, J. Alloys Compd., 2010, 489, p 103–109

D. Spitzer, M. Comet, C. Baras, V. Pichot, and N. Piazzon, Energetic Nano-Materials: Opportunities for Enhanced Performances, J. Phys. Chem. Solids, 2010, 71(2), p 100–108

E.M. Hunt, S. Malcolm, M.L. Pantoya, and F. Davis, Impact Ignition of Nano and Micron Composite Energetic Materials, Int. J. Impact Eng, 2009, 36(6), p 842–846

H. Ren, X. Liu, and J. Ning, Microstructure and Mechanical Properties of W-Zr Reactive Materials, Mater. Sci. Eng., A, 2016, 660, p 205–212

F.Y. Xu, S.B. Liu, Y.F. Zheng, Q.B. Yu, and H.F. Wang, Quasi-Static Compression Properties and Failure of PTFE/Al/W Reactive Materials, Adv. Eng. Mater., 2017, 19(1), p 1–7

M.N. Raftenberg, W. Mock, and G.C. Kirby, Modeling the Impact Deformation of Rods of a Pressed PTFE/Al Composite Mixture, Int. J. Impact Eng, 2008, 35(12), p 1735–1744

S.W. Kuk, J. Yu, and H.J. Ryu, Effects of Interfacial Al Oxide Layers: Control of Reaction Behavior in Micrometer-Scale Al/Ni Multilayers, Mater. Des., 2015, 84, p 372–377

J. Huang, X. Fang, S. Wu, L. Yang, Z. Yu, and Y. Li, Mechanical Response and Shear-Induced Initiation Properties of PTFE/Al/MoO3 Reactive Composites, Materials, 2018, 11(7), p 1200

E.B. Herbold, J.L. Jordan, and N.N. Thadhani, Effects of Processing and Powder Size on Microstructure and Reactivity in Arrested Reactive Milled Al + Ni, Acta Mater., 2011, 59(17), p 6717–6728

B. Feng, X. Fang, Y.C. Li, S.Z. Wu, Y.M. Mao, and H.X. Wang, Influence of Processing Techniques on Mechanical Properties and Impact Initiation of an Al-PTFE Reactive Material, Cent. Eur. J. Energ. Mater., 2016, 13(4), p 989–1004

E.B. Herbold, V.F. Nesterenko, D.J. Benson, J. Cai, K.S. Vecchio, F. Jiang, J.W. Addiss, S.M. Walley, and W.G. Proud, Particle Size Effect on Strength, Failure, and Shock Behavior in Polytetrafluoroethylene-Al-W Granular Composite Materials, J. Appl. Phys., 2008, 104(10), p 103903

C. Ge, W. Maimaitituersun, Y. Dong, and C. Tian, A Study on the Mechanical Properties and Impact-Induced Initiation Characteristics of Brittle PTFE/Al/W Reactive Materials, Materials, 2017, 10(5), p 452

H. Wang, Y. Li, B. Feng, J. Huang, S. Zhang, and X. Fang, Compressive Properties of PTFE/Al/Ni Composite Under Uniaxial Loading, J. Mater. Eng. Perform., 2017, 26(5), p 2331–2336

S. Sen, M. Lake, J. Wilden, and P. Schaaf, Synthesis and Characterization of Ti/Al Reactive Multilayer Films with Various Molar Ratios, Thin Solid Films, 2017, 631, p 99–105

V.C. Srivastava, T. Singh, S. Ghosh Chowdhury, and V. Jindal, Microstructural Characteristics of Accumulative Roll-Bonded Ni-Al-Based Metal–Intermetallic Laminate Composite, J. Mater. Eng. Perform., 2012, 21(9), p 1912–1918

W. Xiong, X.F. Zhang, L. Zheng, K. Bao, H.H. Chen, and Z.W. Guan, The Shock-Induced Chemical Reaction Behaviour of Al/Ni Composites by Cold Rolling and Powder Compaction, J. Mater. Sci., 2019, 54(8), p 6651–6667

Z. Zhang, H. Zhang, Y. Tang, L. Zhu, Y. Ye, S. Li, and S. Bai, Microstructure, Mechanical Properties and Energetic Characteristics of a Novel High-Entropy Alloy HfZrTiTa0.53, Mater. Des., 2017, 133, p 435–443

D. Gao, C. Guo, F. Jiang, and G. Chen, The Dynamic Compressive Behavior of Wf/Zr-Based Metallic Glass Composites, Mater. Sci. Eng., A, 2015, 641, p 107–115

M. Wang, L. Qiu, X. Zhao, Y. Li, T. Rao, S. He, L. Qin, and J. Tao, Multilayered Al/Ni Energetic Structural Materials with High Energy Density and Mechanical Properties Prepared by a Facile Approach of Electrodeposition and Hot Pressing, Mater. Sci. Eng., A, 2019, 757, p 23–31

X. Yang, H. Yang, and S. Zhang, Rate-Dependent Constitutive Models of S690 High-Strength Structural Steel, Constr. Build. Mater., 2019, 198, p 597–607

F. Jiang and K.S. Vecchio, Hopkinson Bar Loaded Fracture Experimental Technique: A Critical Review of Dynamic Fracture Toughness Tests, Appl. Mech. Rev., 2009, 62, p 060802

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51475231) and the Funding of Jiangsu Innovation Program for Graduate Education (No. KYLX16_0348).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, M., Li, J., Zhang, J. et al. Microstructure Evolution and Compressive Properties of Multilayered Al/Ni Energetic Structural Materials under Different Strain Rates. J. of Materi Eng and Perform 29, 506–514 (2020). https://doi.org/10.1007/s11665-020-04589-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04589-0