Abstract

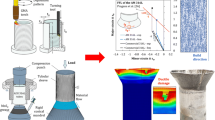

An innovative manufacturing method to fabricate tubular parts made of tungsten heavy alloy (THA) by diffusion bonding of sintered semicircular tubes is proposed and characterized in this study. THAs are produced by blending tungsten grains with a lower-melting-point Ni-Fe binder metal. During the liquid phase sintering (LPS) process of THA, the Ni-Fe liquid wets the tungsten and provides a soluble diffusion network for rapid sintering. Multi-phase THAs are usually very difficult to produce as a tubular piece. During the LPS of the powder compact, a gravity-induced slumping leads to some distortion in the bottom of the tubular parts. One possible alternative to handle this problem is to combine the segmented THA pieces by solid-state diffusion bonding to build up tubular piece. Thus, this study proposes combining the semicircular THA tubes using the diffusion bonding technique to manufacture the tubular THA parts. To provide uniform contact pressures along the joining surfaces, horizontal diffusion bonding is performed using a specially constructed supporting apparatus to reduce the gravity effect. An industry-applicable tube manufacturing process has been well characterized, and its feasibility has been demonstrated by bond quality that was assessed by optical metallography and mechanical testing.

Similar content being viewed by others

References

R.M. German, P. Suri, and S.J. Park, Review: Liquid Phase Sintering, J. Mater. Sci., 2009, 44(1), p 1–39

J. Liu and R.M. German, Microstructural Parameters Related to Liquid-Phase Sintering, Metall. Mater. Trans. A, 2000, 31(10), p 2607–2614

J. Liu and R.M. German, Grain Boundary Sliding and Component Shape Distortion during Liquid-Phase Sintering, Metall. Mater. Trans. A, 2001, 32(8), p 2087–2095

J. Shen, L. Campbell, P. Suri, and R.M. German, Quantitative Microstructure Analysis of Tungsten Heavy Alloys (W-Ni-Cu) during Initial Stage Liquid Phase Sintering, Int. J. Refract. Met. Hard Mater., 2005, 23(2), p 99–108

Y. Yu, M. Zu, C. Ren, and W. Zhang, Effect of Strain Rate on the Plastic Deformation and Fracture of 90W-7Ni-3Fe Alloy Prepared by Liquid-Phase Sintering, J. Mater. Eng. Perform., 2018, 27, p 6606–6615

O. Dinçer, M.K. Pehlivanoğlu, N.K. Çalişkan, İ. Karakaya, and A. Kalkanli, Processing and Microstructural Characterization of Liquid Phase Sintered Tungsten–Nickel–Cobalt Heavy Alloys, Int. J. Refract. Met. Hard Mater., 2015, 50, p 106–112

R.M. German, A. Griffo, and Y. Liu, Gravitational Effects on Grain Coarsening during Liquid-Phase Sintering, Metall. Mater. Trans. A, 1997, 28(1), p 215–221

P. Lu, X. Xu, W. Yi, and R.M. German, Porosity Effect on Densification and Shape Distortion in Liquid Phase Sintering, Mater. Sci. Eng. A, 2001, 318(1–2), p 111–121

H.F. Wang, J.T. Han, and Q.L. Hao, Influence of Mandrel on the Performance of Titanium Tube with Cold Rotary Swaging, Mater. Manuf. Process., 2015, 30(10), p 1251–1255

H. Al-Khazraji, E. El-Danaf, M. Wollmann, and L. Wagner, Microstructure, Mechanical, and Fatigue Strength of Ti-54M Processed by Rotary Swaging, J. Mater. Eng. Perform., 2015, 24, p 2074–2084

E. Simonetto, A. Ghiotti, and S. Bruschi, Dynamic Detection of Tubes Wrinkling in Three Roll Push Bending, Procedia Eng., 2017, 207, p 2316–2321

T.D. Kil, J.M. Lee, and Y.H. Moon, Quantitative Formability Estimation of Ring Rolling Process by Using Deformation Processing Map, J. Mater. Process. Technol., 2015, 220, p 224–230

W. Chen, J. Jiang, D. Li, T. Zou, and Y. Peng, Flower Pattern and Roll Positioning Design for the Cage Roll Forming Process of ERW Pipes, J. Mater. Process. Technol., 2019, 264, p 295–312

S.Y. Kim, B.D. Joo, S. Shin, C.J. Van Tyne, and Y.H. Moon, Discrete Layer Hydroforming of Three-Layered Tubes, Int. J. Mach. Tools Manuf., 2013, 68, p 56–62

H.K. Yi, E.J. Pavlina, C.J. Van Tyne, and Y.H. Moon, Application of a Combined Heating System for the Warm Hydroforming of Lightweight Alloy Tubes, J. Mater. Process. Technol., 2008, 203(1–3), p 532–536

S.W. Han, Y.Y. Woo, T.W. Hwang, I.Y. Oh, and Y.H. Moon, Tailor Layered Tube Hydroforming for Fabricating Tubular Parts with Dissimilar Thickness, Int. J. Mach. Tools Manuf., 2019, 138, p 51–65

J.Y. Park, S.W. Han, H.S. Jeong, J.R. Cho, and Y.H. Moon, Advanced Sealing System to Prevent Leakage in Hydroforming, J. Mater. Process. Technol., 2017, 247, p 103–110

H.K. Nirala and A. Agrawal, A Novel Electromagnetic Fixture for Incremental Sheet Metal Forming, J. Manuf. Sci. Eng., 2019, 141(3), p 1–10

H. Park, D. Kim, J. Lee, S.J. Kim, Y. Lee, and Y.H. Moon, Effect of an Aluminum Driver Sheet on the Electromagnetic Forming of DP780 Steel Sheet, J. Mater. Process. Technol., 2016, 235, p 158–170

P. Ashwath and M.A. Xavior, Effect of Ceramic Reinforcements on Microwave Sintered Metal Matrix Composites, Mater. Manuf. Process., 2018, 33(1), p 7–12

M. Hasan, J. Zhao, Z. Huang, H. Wu, F. Jia, and Z. Jiang, Effects of Holding Time on the Sintering of Cemented Tungsten Carbide Powder and Bonding with High-Strength Steel Wire, J. Mater. Eng. Perform., 2019, https://doi.org/10.1007/s11665-019-04153-5

A.H. Assari and B. Eghbali, Solid State Diffusion Bonding Characteristics at the Interfaces of Ti and Al Layers, J. Alloys Compd., 2019, 773, p 50–58

B. Wang, F. Zhang, S.L. Chen, and S. Kou, Computational Simulation of Diffusion Process in Multicomponent and Multiphase Systems in Diffusion Bonding, Sci. Technol. Weld. Join., 2013, 18(6), p 451–457

B.D. Joo, J.H. Jang, J.H. Lee, Y.M. Son, and Y.H. Moon, Selective Laser Melting of Fe-Ni-Cr Layer on AISI, H13 Tool Steel, Trans. Nonferrous Met. Soc. China, 2009, 19(4), p 921–924

J.H. Jang, B.D. Joo, C.J. VanTyne, and Y.H. Moon, Characterization of Deposited Layer Fabricated by Direct Laser Melting Process, Met. Mater. Int., 2013, 19, p 497–506

N. Senthilnathan, A.R. Annamalai, and G. Venkatachalam, Sintering of Tungsten and Tungsten Heavy Alloys of W-Ni-Fe and W-Ni-Cu: A Review, Trans. Indian Inst. Met., 2017, 70(5), p 1161–1176

R. Bollina and R.M. German, Heating Rate Effects on Microstructural Properties of Liquid Phase Sintered Tungsten Heavy Alloys, Int. J. Refract. Met. Hard Mater., 2004, 22(2–3), p 117–127

B. Cheng, B. Lane, J. Whiting, and K. Chou, A Combined Experimental-Numerical Method to Evaluate Powder Thermal Properties in Laser Powder Bed Fusion, J. Manuf. Sci. Eng., 2018, 140(11), p 111008

S. Stan, M. Chisamera, I. Riposan, L. Neacsu, A.M. Cojocaru, and I. Stan, Integrated System of Thermal/Dimensional Analysis for Quality Control of Metallic Melt and Ductile Iron Casting Solidification, J. Mater. Eng. Perform., 2018, 27, p 5187–5196

A. Bose and R.M. German, Sintering Atmosphere Effects on Tensile Properties of Heavy Alloys, Metall. Trans. A, 1988, 19(10), p 2467–2476

T.W. Hwang, Y.Y. Woo, S.W. Han, and Y.H. Moon, Functionally Graded Properties in Directed-Energy-Deposition Titanium Parts, Opt. Laser Technol., 2018, 105, p 80–88

D.K. Kim, Y.Y. Woo, K.S. Park, W.J. Sim, and Y.H. Moon, Advanced Induction Heating System for Hot Stamping, Int. J. Adv. Manuf. Technol., 2018, 99(1–4), p 583–593

H.K. Jung, C.G. Kang, and Y.H. Moon, Induction Heating of Semisolid Billet and Control of Globular Microstructure to Prevent Coarsening Phenomena, J. Mater. Eng. Perform., 2000, 9, p 12–23

M.C. Song and Y.H. Moon, Coupled Electromagnetic and Thermal Analysis of Induction Heating for the Forging of Marine Crankshafts, Appl. Therm. Eng., 2016, 98, p 98–109

M. Li, D. Ruprecht, G. Kracker, T. Höschen, and R. Neu, Impact of Heat Treatment on Tensile Properties of 97W2Ni1Fe Heavy Alloy, J. Nucl. Mater., 2018, 512, p 1–7

I.S. Humail, F. Akhtar, S.J. Askari, M. Tufail, and X. Qu, Tensile Behavior Change Depending on the Varying Tungsten Content of W-Ni-Fe Alloys, Int. J. Refract. Met. Hard Mater., 2007, 25(5–6), p 380–385

J. Das, G.A. Rao, and S.K. Pabi, Microstructure and Mechanical Properties of Tungsten Heavy Alloys, Mater. Sci. Eng. A, 2010, 527, p 7841–7847

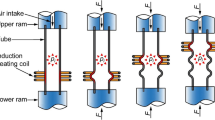

Z.S. Park, S. Lee, T. Lee, J.H. Kim, and Y.H. Moon, Fabrication of long tubular parts made of tungsten-heavy alloys by inductive bonding of multiple tubes, Int. J. Refract. Met. Hard Mater., 2019, 85, p 105058

Acknowledgment

This work was partially supported by a National Research Foundation of Korea (NRF) Grant funded by the Korean Government (MSIP) (No. 2012R1A5A1048294).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Park, Z.S., Han, S.W., Kim, J.H. et al. Manufacture of Tungsten Heavy Alloy Tube by Diffusion Bonding of Semicircular Tubes. J. of Materi Eng and Perform 29, 699–711 (2020). https://doi.org/10.1007/s11665-020-04587-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04587-2