Abstract

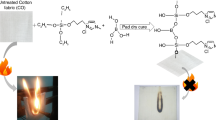

This work aims to prepare a series of sols based on Titanium (IV) butoxide (TBT) and using boric acid as a functional additive. The sols were applied onto the cotton fabric by the pad-pry-cure process. The as-obtained cotton fabrics were characterized using Fourier-transform infrared (FTIR) spectroscopy and scanning electron microscopy (SEM) analysis in order to determine their chemical composition and their surface morphology, respectively. The results indicate the formation of TiO2–boron-based coating over the surface of coated cotton fabric. X-ray diffraction (XRD) patterns showed that the coating did not affect the crystallographic structure of the cellulosic fabric. The functional properties of the treated samples were measured from thermo-oxidative stability and burning behavior performance, drop absorption and water uptake measurements. The results showed that the coated cotton fabrics by the sol–gel approach through the application of TiO2–boron-based coating with 2.5 molar ratio of boric acid possessed high thermal stability and flame retardancy. Most importantly, a total burning time of 2 s and a residue of more than 90% were obtained after 10 s of flame application, indicating that the functionalized cotton fabric self-extinguished the fire rapidly. The water-repellent properties were also enhanced and the obtained results mentioned that the drop time and the water uptake were improved compared with untreated cotton fabric. The effect of the application of TiO2–boron-based coatings on the mechanical properties of cotton samples, as well as their washing fastness were studied.

Highlights

-

A series of sols based on Titanium (IV) butoxide and boric acid have been synthesized at a different molar ratio of boric acid from 0.1 to 2.5.

-

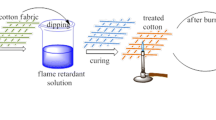

The prepared sols were applied to the surface of the cotton fabric by the pad-dry-cure process.

-

The production of cotton fabric with flame-retardant (FR) and hydrophobic properties through the application of TiO2–boron-based coating has been successfully achieved.

-

Good flame-retardant property and thermal stability, as well as, water repellence of modified cotton fabric, were found at 2.5 molar ratio of boric acid.

Similar content being viewed by others

References

Elmogahzy Y, Farag R (2018) Tensile properties of cotton fibers: importance, research, and limitations. In: Handbook of properties of textile and technical fibres, 2nd edn. Elsevier, pp 223–273

Horrocks AR (1996) Developments in flame retardants for heat and fire resistant textiles—the role of char formation and intumescence. Polym Degrad Stab 54(2–3):143–154

Xue C-H, Zhang L, Wei P, Jia S-T (2016) Fabrication of superhydrophobic cotton textiles with flame retardancy. Cellulose 23(2):1471–1480. https://doi.org/10.1007/s10570-016-0885-2

Qiu X, Li Z, Li X, Zhang Z (2017) Flame retardant coatings prepared by layer by layer assembly: a review. Chem Eng J 334:108–122

Ma Y, Cao C, Hou C (2018) Preparation of super-hydrophobic cotton fabric with crosslinkable fluoropolymer. 477:955–962. https://doi.org/10.1007/978-981-10-7629-9_119

Tsafack MJ, Levalois-Grützmacher J (2006) Flame retardancy of cotton textiles by plasma-induced graft-polymerization (PIGP). Surf Coat Technol 201(6):2599–2610

Zhang D, Williams BL, Shrestha SB, Nasir Z, Becher EM, Lofink BJ, Santos VH, Patel H, Peng X, Sun L (2017) Flame retardant and hydrophobic coatings on cotton fabrics via sol–gel and self-assembly techniques. J Colloid Interface Sci 505:892–899. https://doi.org/10.1016/j.jcis.2017.06.087

Ismail WNW (2016) Sol–gel technology for innovative fabric finishing—a review. J Sol-Gel Sci Technol 78:698–707

Vasiljević J, Tomšič B, Jerman I, Simončič B (2017) Organofunctional trialkoxysilane sol–gel precursors for chemical modification of textile fibres. Tekstilec 60:198–213

Vasiljević J, Zorko M, Štular D, et al. (2017) Structural optimisation of a multifunctional water-and oil-repellent, antibacterial, and flame-retardant sol–gel coating on cellulose fibres. Cellulose 24:1511–1528

Vasiljević J, Tomšič B, Jerman I, et al. (2014) Multifunctional superhydrophobic/oleophobic and flame-retardant cellulose fibres with improved ice-releasing properties and passive antibacterial activity prepared via the sol–gel method. J Sol-Gel Sci Technol 70:385–399

Vasiljević J, Tomšič B, Jerman I, et al. (2014) Novel multifunctional water-and oil-repellent, antibacterial, and flame-retardant cellulose fibres created by the sol–gel process. Cellulose 21(4):2611–2623

Castellano A, Colleoni C, Iacono G, et al. (2019) Synthesis and characterization of a phosphorous/nitrogen based sol–gel coating as a novel halogen-and formaldehyde-free flame retardant finishing for cotton fabric. Polym Degrad Stab 162:148–159

Luo X, Weng Y, Wang S, et al. (2019) Superhydrophobic and oleophobic textiles with hierarchical micro-nano structure constructed by sol–gel method. J Sol-Gel Sci Technol 89:820–829

Poli R, Colleoni C, Calvimontes A, et al. (2015) Innovative sol–gel route in neutral hydroalcoholic condition to obtain antibacterial cotton finishing by zinc precursor. J Sol-Gel Sci Technol 74:151–160

Camlibel NO, Arik B (2017) Sol–gel applications in textile finishing processes. In: Recent applications in sol–gel synthesis. Recent Appl Sol-Gel Synth IntechOpen Ltd UK, pp 253–281

Rivero P, Goicoechea J (2016) Sol–gel technology for antimicrobial textiles. In: Antimicrobial textiles. Elsevier, Cambridge, pp 47–72. https://doi.org/10.1016/B978-0-08-100576-7.00004-3

Boukhriss A, Gmouh S, Hannach H, Roblin J-P, Cherkaoui O, Boyer D (2016) Treatment of cotton fabrics by ionic liquid with PF6—anion for enhancing their flame retardancy and water repellency. Cellulose 23(5):3355–3364. https://doi.org/10.1007/s10570-016-1016-9

Bentis A, Boukhriss A, Grancaric AM, El Bouchti M, El Achaby M, Gmouh S (2019) Flammability and combustion behavior of cotton fabrics treated by the sol gel method using ionic liquids combined with different anions. Cellulose. https://doi.org/10.1007/s10570-018-2206-4

Boukhriss A, Boyer D, Hannache H, Roblin J-P, Mahiou R, Cherkaoui O, Therias S, Gmouh S (2015) Sol–gel based water repellent coatings for textiles. Cellulose 22(2):1415–1425

Bentis A, Boukhriss A, Boyer D, Gmouh S (2017) Development of flame retardant cotton fabric based on ionic liquids via sol–gel technique. IOP Publishing, UK, p 122001

Deh S, Gähr F, Buchmeiser MR (2016) Synergistic effects in the pyrolysis of phosphorus-based flame-retardants: the role of Si-and N-based compounds. Polym Degrad Stab 130:155–164

Rosace G, Castellano A, Trovato V, et al. (2018) Thermal and flame retardant behaviour of cotton fabrics treated with a novel nitrogen-containing carboxyl-functionalized organophosphorus system. Carbohydr Polym 196:348–358

Aksit A, Onar N, Kutlu B, et al. (2016) Synergistic effect of phosphorus, nitrogen and silicon on flame retardancy properties of cotton fabric treated by sol–gel process. Int J Cloth Sci Technol 28:319–327

Grancaric AM, Colleoni C, Guido E, Botteri L, Rosace G (2017) Thermal behaviour and flame retardancy of monoethanolamine-doped sol–gel coatings of cotton fabric. Prog Org Coat 103:174–181

Zhang Q-H, Zhang W, Chen G-Q, Xing T (2015) Combustion properties of cotton fabric treated by boron doped silica sol. Therm Sci 19:1345–1348

Zhang Q, Gu J, Chen G, Xing T (2016) Durable flame retardant finish for silk fabric using boron hybrid silica sol. Appl Surf Sci 387:446–453

LeVan SL, Tran HC (1990) The role of boron in flame-retardant treatments. In: First International Conference on Wood Protection with Diffusible Preservatives:... Nashville, Tennessee. Forest Products Research Society, Madison, WI, pp 39–41

Dogan GBB (2018) Nano-boron for textiles. U.S. Patent Application No. 15/762,477

Zhang Q, Chen G, Xing T (2017) Silk flame retardant finish by ternary silica sol containing boron and nitrogen. Appl Surf Sci 421:52–60

Liu C, Xing T, Wei B, Chen G (2018) Synergistic effects and mechanism of modified silica sol flame retardant systems on silk fabric. Materials 11:1842

El-Naggar ME, Shaheen TI, Zaghloul S, et al. (2016) Antibacterial activities and UV protection of the in situ synthesized titanium oxide nanoparticles on cotton fabrics. Ind Eng Chem Res 55:2661–2668

Butola B, Garg A, Garg A, Chauhan I (2018) Development of multi-functional properties on cotton fabric by in situ application of TiO2 and ZnO. Nanoparticles 99(1):93–100

El-Shafei A, ElShemy M, Abou-Okeil A (2015) Eco-friendly finishing agent for cotton fabrics to improve flame retardant and antibacterial properties. Carbohydr Polym 118:83–90

Cheng X-W, Guan J-P, Yang X-H, Tang R-C (2017) Improvement of flame retardancy of silk fabric by bio-based phytic acid, nano-TiO2, and polycarboxylic acid. Prog Org Coat 112:18–26

Ortelli S, Malucelli G, Blosi M, et al. (2019) NanoTiO2@ DNA complex: a novel eco, durable, fire retardant design strategy for cotton textiles. J Colloid Interface Sci 546:174–183

Ortelli S, Malucelli G, Cuttica F, et al. (2018) Coatings made of proteins adsorbed on TiO2 nanoparticles: a new flame retardant approach for cotton fabrics. Cellulose 25:2755–2765

Chen X, Mao SS (2007) Titanium dioxide nanomaterials: synthesis, properties, modifications, and applications. Chem Rev 107:2891–2959

Cheng X-W, Guan J-P, Yang X-H, Tang R-C (2018) Durable flame retardant wool fabric treated by phytic acid and TiO2 using an exhaustion-assisted pad-dry-cure process. Thermochim Acta 665:28–36

Arju SN, Ali MA (2017) Chemical modification of jute fibers for improving its hydrophobicity and dyeability with reactive dyes. World J Res Rev 5

Colleoni C, Guido E, Migani V, Rosace G (2015) Hydrophobic behaviour of non-fluorinated sol–gel based cotton and polyester fabric coatings. J Ind Text 44(6):815–834

Mahltig B, Audenaert F, Böttcher H (2005) Hydrophobic silica sol coatings on textiles—the influence of solvent and sol concentration. J sol–gel Sci Technol 34(2):103–109

Algar I, Fernandes SC, Mondragon G, et al. (2015) Pineapple agroindustrial residues for the production of high value bacterial cellulose with different morphologies. J Appl Polym Sci 132:41237

Uddin M, Cesano F, Bonino F, Bordiga S, Spoto G, Scarano D, Zecchina A (2007) Photoactive TiO2 films on cellulose fibres: synthesis and characterization. J Photochemistry Photobiol A: Chem 189(2–3):286–294

Rosace G, Canton R, Colleoni C (2010) Plasma enhanced CVD of SiOxCyHz thin film on different textile fabrics: influence of exposure time on the abrasion resistance and mechanical properties. Appl Surf Sci 256(8):2509–2516

Yu J, Pang Z, Zheng C, Zhou T, Zhang J, Zhou H, Wei Q (2019) Cotton fabric finished by PANI/TiO2 with multifunctions of conductivity, anti-ultraviolet and photocatalysis activity. Appl Surf Sci 470:84–90

Foorginezhad S, Zerafat M (2019) Fabrication of stable fluorine-free superhydrophobic fabrics for anti-adhesion and self-cleaning properties. Appl Surf Sci 464:458–471

Daoud WA, Leung S, Tung W, Xin J, Cheuk K, Qi K (2008) Self-cleaning keratins. Chem Mater 20(4):1242–1244

Pakdel E, Daoud WA (2013) Self-cleaning cotton functionalized with TiO2/SiO2: focus on the role of silica. J Colloid Interface Sci 401:1–7

El messoudi M, Boukhriss A, Cherkaoui O, Gmouh S (2019) Adsorption–desorption kinetics of silica coated on textile fabrics by the sol–gel process. J Coat Technol Res 1–10

Shaheen TI, Salem SS, Zaghloul S (2019) A new facile strategy for multifunctional textiles development through in situ deposition of SiO2/TiO2 nanosols hybrid. Ind Eng Chem Res 58:20203–20212

Yildirim M, Kipcak A, Senberber F, et al. (2015) The determination of the potassium nitrate, sodium hydroxide and boric acid molar ratio in the synthesis of potassium borates via hydrothermal method. World Acad Sci Eng Technol Int J Chem Mol Nucl Mater Met Eng 9:597–600

Alongi J, Malucelli G (2013) Thermal stability, flame retardancy and abrasion resistance of cotton and cotton–linen blends treated by sol–gel silica coatings containing alumina micro-or nano-particles. Polym Degrad Stab 98(8):1428–1438

Yang P, Kokot S (1996) Thermal analysis of different cellulosic fabrics. J Appl Polym Sci 60(8):1137–1146

He P, Chen X, Zhu P, Liu J, Fan G, Sui S, Lu Z, Dong C (2018) Preparation and flame retardancy of reactive flame retardant for cotton fabric. J Therm Anal Calorim. 1–11

Soares S, Camino G, Levchik S (1995) Comparative study of the thermal decomposition of pure cellulose and pulp paper. 49(2):275–283

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bentis, A., Boukhriss, A. & Gmouh, S. Flame-retardant and water-repellent coating on cotton fabric by titania–boron sol–gel method. J Sol-Gel Sci Technol 94, 719–730 (2020). https://doi.org/10.1007/s10971-020-05224-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05224-z