Abstract

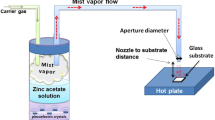

Ultrasonic mist vapor deposition (UMVD) is a widely used facile technique to prepare ZnO thin films. The surface properties of prepared thin films can be tuned via easily controllable UMVD deposition parameters. Herein, we utilized an oblique angle (OA) geometry in UMVD system named as OA-UMVD. The angle between incident flow and substrate (θs) was changed from 0° to 45°. Alteration of θs as well as substrate temperature (Ts) resulted in the deposition of ZnO thin films with different morphologies. For mild nozzle–substrate distance (D = 3 cm), fine vertical ZnO nanosheets with length of 123 nm and thickness of 23 nm were obtained for low Ts (330 °C) and small θs (≈ 0°). By increasing both Ts and θs, ZnO nanorods gradually appeared on the surface. Both nozzle–substrate distance (D) and Ts showed similar effect on deposition rate (Rd), and Rd decreased by increase of D and Ts, while deposition rate increased for larger θs. Confocal microscopy results revealed that using low Ts (330 °C), short distance (D = 1.5 cm) and large θs (45°) resulted in high macroscopic surface roughness (MRs) of 98 nm, while high Ts (500 °C), long D (5 cm) and small θs (≈ 0○) created compact and smooth surface with low MRs of 5 nm, in accordance with transmittance results. The ZnO wurtzite crystal structure was approved via X-ray diffraction patterns. The crystallite size in the layers was affected only by Ts, and θs had no significant effect on the layers’ crystallinity. Obtaining different ZnO nanostructures with different MRs via easily and accurately controllable growth parameters is a great advantage for our employed OA-UMVD system, which could be used to prepare ZnO thin films with desired morphologies for widespread application fields.

Similar content being viewed by others

References

H. Alehdaghi, M. Marandi, A. Irajizad, N. Taghavinia, J. Jang, H. Zare, Mater. Chem. Phys. 204, 262 (2018). https://doi.org/10.1016/j.matchemphys.2017.10.051

Y. Al-Douri, A.J. Haider, A.H. Reshak, A. Bouhemadou, M. Ameri, Optik 127(20), 10102 (2016). https://doi.org/10.1016/j.ijleo.2016.08.012

M. Samadi, M. Zirak, A. Naseri, M. Kheirabadi, M. Ebrahimi, A.Z. Moshfegh, Res. Chem. Intermed. 45(4), 2197 (2019). https://doi.org/10.1007/s11164-018-03729-5

M. Samadi, M. Zirak, A. Naseri, E. Khorashadizade, A.Z. Moshfegh, Thin Solid Films 605, 2 (2016). https://doi.org/10.1016/j.tsf.2015.12.064

P. Tiwana, P. Docampo, M.B. Johnston, H.J. Snaith, L.M. Herz, ACS Nano 5(6), 5158 (2011)

F. Benosman, Z. Dridi, Y. Al-Douri, B. Bouhafs, Int. J. Mod. Phys. B 30(31), 1650225 (2016). https://doi.org/10.1142/s0217979216502258

W. Zhang, S. Chang, S. Yao, H. Wang, J. Electron. Mater. 48(8), 4895 (2019). https://doi.org/10.1007/s11664-019-07278-4

M. Ahmadi, M. Shafiey Dehaj, S. Ghazanfarpour, S. Ghazanfarpour, Appl. Phys. A 125(9), 604 (2019). https://doi.org/10.1007/s00339-019-2882-4

F. Liu, X. Chen, X. Wang, Y. Han, X. Song, J. Tian, X. He, H. Cui, Sens. Actuators B Chem. 291, 155 (2019). https://doi.org/10.1016/j.snb.2019.04.009

F. Khosravi-Nejad, M. Teimouri, S. Jafari Marandi, M. Shariati, Appl. Phys. A 125(9), 616 (2019). https://doi.org/10.1007/s00339-019-2890-4

N.N. Jandow, A.K. Elttayef, A.F. Majied, N.F. Habubi, N. Saadeddin, Y. Al-Douri, A.I.P. Conf, Proc. 2083(1), 020003 (2019). https://doi.org/10.1063/1.5094306

N.K. Hassan, M.R. Hashim, Y. Al-Douri, Optik 125(11), 2560 (2014). https://doi.org/10.1016/j.ijleo.2013.10.023

M. Zirak, O. Akhavan, O. Moradlou, Y.T. Nien, A.Z. Moshfegh, J. Alloys Compd. 590, 507 (2014). https://doi.org/10.1016/j.jallcom.2013.12.158

M. Zirak, O. Moradlou, M.R. Bayati, Y.T. Nien, A.Z. Moshfegh, Appl. Surf. Sci. 273, 391 (2013). https://doi.org/10.1016/j.apsusc.2013.02.050

M. Zirak, H. Oveisi, J. Lin, Y. Bando, A.A. Alshehri, J. Kim, Y. Ide, M.S.A. Hossain, V. Malgras, Y. Yamauchi, Bull. Chem. Soc. Jpn. 91(10), 1556 (2018). https://doi.org/10.1246/bcsj.20180108

C. Ma, Z. Liu, Z. Tong, C. Han, Q. Cai, Appl. Phys. A 125(7), 451 (2019). https://doi.org/10.1007/s00339-019-2742-2

H. Alehdaghi, M. Marandi, A. Irajizad, N. Taghavinia, Org. Electron. 16, 87 (2015). https://doi.org/10.1016/j.orgel.2014.10.038

J.F.S. Fernando, C. Zhang, K.L. Firestein, J.Y. Nerkar, D.V. Golberg, J. Mater. Chem. A 7(14), 8460 (2019). https://doi.org/10.1039/C8TA12511B

H. Sun, S.-C. Chen, C.-H. Wang, Y.-W. Lin, C.-K. Wen, T.-H. Chuang, X. Wang, S.-S. Lin, M.-J. Dai, Surf. Coat. Technol. 359, 390 (2019). https://doi.org/10.1016/j.surfcoat.2018.10.105

A. Mameli, B. Karasulu, M.A. Verheijen, B. Barcones, B. Macco, A.J.M. Mackus, W.M.M.E. Kessels, F. Roozeboom, Chem. Mater. 31(4), 1250 (2019). https://doi.org/10.1021/acs.chemmater.8b03165

C.-Q. Luo, F.C.-C. Ling, M.A. Rahman, M. Phillips, C. Ton-That, C. Liao, K. Shih, J. Lin, H.W. Tam, A.B. Djurišić, S.-P. Wang, Appl. Surf. Sci. 483, 1129 (2019). https://doi.org/10.1016/j.apsusc.2019.03.228

R. Bhujel, S. Rai, B.P. Swain, Mater. Sci. Semicond. Process. 102, 104592 (2019). https://doi.org/10.1016/j.mssp.2019.104592

R. Al-Gaashani, S. Radiman, A. Daud, N. Tabet, Y. Al-Douri, Ceram. Int. 39(3), 2283 (2013)

P. Steiger, J. Zhang, K. Harrabi, I.A. Hussein, J.M. Downing, M.A. McLachlan, Thin Solid Films 645, 417 (2018). https://doi.org/10.1016/j.tsf.2017.11.021

M. Pérez-González, S.A. Tomás, J. Santoyo-Salazar, S. Gallardo-Hernández, M.M. Tellez-Cruz, O. Solorza-Feria, J. Alloys Compd. 779, 908 (2019). https://doi.org/10.1016/j.jallcom.2018.11.302

M. Kashif, Y. Al-Douri, U. Hashim, M. Ali, S. Ali, M. Willander, Micro. Nano Lett. 7(2), 163 (2012)

K. Gherab, Y. Al-Douri, C.H. Voon, U. Hashim, M. Ameri, A. Bouhemadou, Result Phys. 7, 1190 (2017). https://doi.org/10.1016/j.rinp.2017.03.013

N. Hassan, M. Hashim, Y. Al-Douri, K. Al-Heuseen, Int. J. Electrochem. Sci. 7, 4625 (2012)

Y.J. Onofre, A.C. Catto, S. Bernardini, T. Fiorido, K. Aguir, E. Longo, V.R. Mastelaro, L.F. da Silva, M.P.F. de Godoy, Appl. Surf. Sci. 478, 347 (2019). https://doi.org/10.1016/j.apsusc.2019.01.197

H. Alehdaghi, M. Zirak, J. Mater. Sci. Mater. Electron. 30(3), 2706 (2019). https://doi.org/10.1007/s10854-018-0546-3

S. Benramache, Y. Aoun, A. Charef, B. Benhaoua, S. Lakel, Inorg. Nano–Micro Chem. 49(6), 177 (2019). https://doi.org/10.1080/24701556.2019.1624568

Y. Kamada, T. Kawaharamura, H. Nishinaka, S. Fujita, Jpn. J. Appl. Phys. 45(32), L857 (2006). https://doi.org/10.1143/jjap.45.l857

V. Mata, A. Maldonado, O.M. de la Luz, Mater. Sci. Semicond. Process. 75, 288 (2018). https://doi.org/10.1016/j.mssp.2017.11.038

H. Tanoue, M. Takenouchi, T. Yamashita, S. Wada, Z. Yatabe, S. Nagaoka, Y. Naka, Y. Nakamura, Phys. Stat. Solid. A Appl. Mater. Sci. (2017). https://doi.org/10.1002/pssa.201600603

H. Tanoue, T. Taniguchi, S. Wada, S. Yamamoto, S. Nakamura, Y. Naka, H. Yoshikawa, M. Munekata, S. Nagaoka, Y. Nakamura, Appl. Phys. Express (2015). https://doi.org/10.7567/apex.8.125502

H.L. Ma, Z.W. Liu, D.C. Zeng, M.L. Zhong, H.Y. Yu, E. Mikmekova, Appl. Surf. Sci. 283, 1006 (2013). https://doi.org/10.1016/j.apsusc.2013.07.060

K. Takenaka, Y. Okumura, Y. Setsuhara, Jpn. J. Appl. Phys. (2013). https://doi.org/10.7567/jjap.52.01ac11

K. Takenaka, Y. Okumura, Y. Setsuhara, Jpn. J. Appl. Phys. (2012). https://doi.org/10.1143/jjap.51.08hf05

E. Gungor, T. Gungor, Adv. Mater. Sci. Eng. (2012). https://doi.org/10.1155/2012/594971

S. Edinger, J. Bekacz, M. Richter, R. Hamid, R.A. Wibowo, A. Peic, T. Dimopoulos, Thin Solid Films 594, 238 (2015). https://doi.org/10.1016/j.tsf.2015.04.027

J. Cheng, R. Hu, Q. Wang, C.X. Zhang, Z. Xie, Z.W. Long, X. Yang, L. Li, Int. J. Photoenergy (2015). https://doi.org/10.1155/2015/201472

J.H. Min, X.Y. Liang, B. Wang, Y. Zhao, Y. Guo, L.J. Wang, Adv. Mater. Res. 299–300, 475 (2011). https://doi.org/10.4028/www.scientific.net/AMR.299-300.475

E. Emil, G. Alkan, S. Gurmen, R. Rudolf, D. Jenko, B. Friedrich, Metals (2018). https://doi.org/10.3390/met8080569

W.G. Yang, Z. Yang, D. Li, X.Y. Zhang, Z.L. Zhou, S. Tian, Y.Q. Tong, C.H. Xia, M. Liu, L. Li, F. Wang, Mod Phys Lett B (2018). https://doi.org/10.1142/s0217984918503517

N. Zebbar, M. Trari, M. Doulache, A. Boughelout, L. Chabane, Appl. Surf. Sci. 292, 837 (2014). https://doi.org/10.1016/j.apsusc.2013.12.059

H. In Sub, P. Il-Kyu, Korean J Mater Res 27(11), 609 (2017)

A.J. Wang, H. Chen, T.F. Chen, Z.L. Wu, Y.L. Li, Y.S. Wang, J. Nanosci. Nanothech. 14(5), 3804 (2014). https://doi.org/10.1166/jnn.2014.7952

S. Benramache, B. Benhaoua, F. Chabane, A. Guettaf, Optik 124(18), 3221 (2013). https://doi.org/10.1016/j.ijleo.2012.10.001

N. Zebbar, Y. Kheireddine, K. Mokeddem, A. Hafdallah, M. Kechouane, M.S. Aida, Mater. Sci. Semicond. Process. 14(3–4), 229 (2011). https://doi.org/10.1016/j.mssp.2011.03.001

X. Zhao, J. Cheng, J. Mater. Sci. Mater. Electron. 27(3), 2676 (2016). https://doi.org/10.1007/s10854-015-4076-y

C. Biswas, Z. Ma, X.D. Zhu, T. Kawaharamura, K.L. Wang, Sol. Energy Mater. Sol. Cells 157, 1048 (2016). https://doi.org/10.1016/j.solmat.2016.08.022

H.-J. Jeon, S.-G. Lee, K.-S. Shin, S.-W. Kim, J.-S. Park, J. Alloys Compd. 614, 244 (2014)

S. Jongthammanurak, M. Witana, T. Cheawkul, C. Thanachayanont, Mater. Sci. Semicond. Process. 16(3), 625 (2013). https://doi.org/10.1016/j.mssp.2012.11.009

M.T. Htay, Y. Tani, Y. Hashimoto, K. Ito, J. Mater. Sci. Mater. Electron. 20, 341 (2009). https://doi.org/10.1007/s10854-008-9613-5

P. Singh, A. Kumar, Deepak, D. Kaur, J. Cryst. Growth 306(2), 303 (2007) https://doi.org/10.1016/j.jcrysgro.2007.05.023

Z.K. Zhang, J.M. Bian, J.C. Sun, X.W. Ma, Y.X. Wang, C.H. Cheng, Y.M. Luo, H.Z. Liu, Mater. Res. Bull. 47(9), 2685 (2012). https://doi.org/10.1016/j.materresbull.2012.05.010

K.H. Kim, K.S. Shin, B. Kumar, K.K. Kim, S.W. Kim, J. Nanoelectron. Optoelectron. 5(2), 247 (2010). https://doi.org/10.1166/jno.2010.1103

K.P. Liu, B.F. Yang, H.W. Yan, Z.P. Fu, M.W. Wen, Y.J. Chen, J. Zuo, Appl. Surf. Sci. 255(5), 2052 (2008). https://doi.org/10.1016/j.apsusc.2008.06.203

T. Kawaharamura, H. Nishinaka, S. Fujita, Jpn. J. Appl. Phys. 47(6), 4669 (2008). https://doi.org/10.1143/jjap.47.4669

L. Munoz-Fernandez, G. Alkan, O. Milosevic, M.E. Rabanal, B. Friedrich, Catal. Today 321, 26 (2019). https://doi.org/10.1016/j.cattod.2017.11.029

M. Khammar, S. Guitouni, N. Attaf, M.S. Aida, A. Attaf, Ceram. Int. 43(13), 9919 (2017). https://doi.org/10.1016/j.ceramint.2017.04.179

A. Gahtar, A. Rahal, B. Benhaoua, S. Benramache, Optik 125(14), 3674 (2014). https://doi.org/10.1016/j.ijleo.2014.01.078

V.K. Jayaraman, A.M. Alvarez, M.D.O. Amador, Mater. Lett. 157, 169 (2015). https://doi.org/10.1016/j.matlet.2015.05.065

G. Kenanakis, N. Katsarakis, E. Koudoumas, Thin Solid Films 555, 62 (2014). https://doi.org/10.1016/j.tsf.2013.10.015

G. Kenanakis, N. Katsarakis, Mater. Res. Bull. 60, 752 (2014). https://doi.org/10.1016/j.materresbull.2014.09.060

O. Dimitrov, D. Nesheva, V. Blaskov, I. Stambolova, S. Vassilev, Z. Levi, V. Tonchev, Mater. Chem. Phys. 148(3), 712 (2014). https://doi.org/10.1016/j.matchemphys.2014.08.039

M.T. Htay, Y. Hashimoto, N. Momose, K. Ito, J. Cryst. Growth 311(20), 4499 (2009). https://doi.org/10.1016/j.jcrysgro.2009.08.008

Y. Benkhetta, A. Attaf, H. Saidi, A. Bouhdjar, H. Benjdidi, I.B. Kherchachi, M. Nouadji, N. Lehraki, Optik 127(5), 3005 (2016). https://doi.org/10.1016/j.ijleo.2015.11.236

Y. Aoun, B. Benhaoua, S. Benramache, B. Gasmi, Optik 126(20), 2481 (2015). https://doi.org/10.1016/j.ijleo.2015.06.025

B. Wang, J.H. Min, Y. Zhao, W.B. Sang, C.J. Wang, Appl. Phys. Lett. (2009). https://doi.org/10.1063/1.3134486

S. Sali, M. Boumaour, M. Kechouane, S. Kermadi, F. Aitamar, Phys. B Cond. Mater. 407(13), 2626 (2012). https://doi.org/10.1016/j.physb.2012.04.009

K. Robbie, M.J. Brett, J. Vac. Sci. Thech. A 15(3), 1460 (1997). https://doi.org/10.1116/1.580562

F. Ynineb, N. Attaf, M.S. Aida, J. Bougdira, Y. Bouznit, H. Rinnert, Thin Solid Films 628, 36 (2017). https://doi.org/10.1016/j.tsf.2017.02.044

O. Gracia-Martinez, R.M. Rojas, E. Vila, J.L. Martin de Vidales, Solid State Ionics 63, 442 (1993)

Y. Zhao, D. Ye, G.-C. Wang, T.-M. Lu, Designing nanostructures by glancing angle deposition. SPIE (2003)

Y.E. Lee, S.G. Kim, Y.J. Kim, H.J. Kim, J. Vac. Sci. Thech. A 15(3), 1194 (1997). https://doi.org/10.1116/1.580592

K. Robbie, M.J. Brett, A. Lakhtakia, Nature 384(6610), 616 (1996). https://doi.org/10.1038/384616a0

A. Yildiz, H. Cansizoglu, M. Turkoz, R. Abdulrahman, A. Al-Hilo, M.F. Cansizoglu, T.M. Demirkan, T. Karabacak, Thin Solid Films 589, 764 (2015). https://doi.org/10.1016/j.tsf.2015.06.058

J. Chu, X. Peng, M. Sajjad, B. Yang, P.X. Feng, Thin Solid Films 520(9), 3493 (2012). https://doi.org/10.1016/j.tsf.2011.12.066

T. Karabacak, G.-C. Wang, T.-M. Lu, J. Vac. Sci. Thech. A 22(4), 1778 (2004). https://doi.org/10.1116/1.1743178

W. Tang, Preparation Principle, Technology and Application of Thin Film Materials (Metallurgical Industry Press, Beijing, 2003)

S.-H. Hu, Y.-C. Chen, C.-C. Hwang, C.-H. Peng, D.-C. Gong, J. Alloys Compd. 500(2), L17 (2010)

P. Yang, H. Yan, S. Mao, R. Russo, J. Johnson, R. Saykally, N. Morris, J. Pham, R. He, H.J. Choi, Adv. Funct. Mater. 12(5), 323 (2002)

R.N. Tait, T. Smy, M.J. Brett, Thin Solid Films 226(2), 196 (1993). https://doi.org/10.1016/0040-6090(93)90378-3

J.M. LaForge, M.T. Taschuk, M.J. Brett, Thin Solid Films 519(11), 3530 (2011). https://doi.org/10.1016/j.tsf.2011.01.241

A. Barranco, A. Borras, A.R. Gonzalez-Elipe, A. Palmero, Prog. Mater. Sci. 76, 59 (2016). https://doi.org/10.1016/j.pmatsci.2015.06.003

Acknowledgement

The financial support of Research and Technology Council of the Hakim Sabzevari University is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Alehdaghi, H., Kazemi, M. & Zirak, M. Facile preparation of ZnO nanostructured thin films via oblique angle ultrasonic mist vapor deposition (OA-UMVD): a systematic investigation. Appl. Phys. A 126, 103 (2020). https://doi.org/10.1007/s00339-020-3295-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-3295-0