Abstract

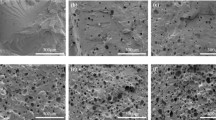

The present paper regards the development of polyurea/polyurethane (PUa/PU) and PUa/PU–silica hybrid shell microcapsules (MCs), loaded with Ongronat®2500, a commercial type of oligomeric methylene diphenyl diisocyanate with increased functionality, as core material. Ongronat® 2500 has a wide range of applications either for the production of rigid polyurethane foams and as cross-linking or self-healing agent. The MCs were achieved by a facile, one-pot process, consisting of an oil-in-water microemulsion system combined with interfacial polymerization processing, employing a higher reactivity isocyanate, toluene diisocyanate, to competitively contribute to the shell formation. Ethylenediamine, polyethylenimine (PEI), triethoxy(octyl)silane (n-OTES) and 3-(2-aminoethylamino) propyltrimethoxysilane (aminosilane) were tested as active, or “latent” active hydrogen (H) sources, and their effect on the MCs morphology, encapsulation yield, shelf life, shell’s chemical structure and thermal stability was assessed. The MCs are aimed at the development of a new generation of adhesive formulations, which are mono-component, self-reactive, eco-friendly and with low health hazards, for industries such as the footwear, construction, aerospace and automotive. MCs’ characterization was performed using Fourier transformed infrared spectroscopy, thermogravimetric analysis and scanning electron microscopy. It was possible to obtain MCs with a high loading of Ongronat®2500, exhibiting a core–shell morphology, an increased shell resistance to temperature and improved shelf life. The combination of PEI and n-OTES led to the best compromise between encapsulation yield and shelf life. Finally, a confinement effect of the encapsulated macromolecules is herein shown for the first time, by the drastic narrowing of the NCO peak at the FTIR spectrum of the MCs.

Similar content being viewed by others

References

Langenberg KV, Warden P, Adam C, Milner HR (2010) The durability of isocyanate based adhesives under service in Australian conditions, the results from a 3 year exposure study and accelerated testing regime (Literature Review), Melbourne, Australia: Forest & Wood Products Australia Limited; 63 p. https://www.fwpa.com.au/images/processing/PNB034-0506_Literature_Review_Isocyanate_Adhesives_0.pdf. Accessed July 2019

Paiva RMM, Marques EAS, Silva LFM, António CAC, Arán-Ais F (2016) Adhesives in the footwear industry. Mater. Des. Appl. 230:357–374. https://doi.org/10.1177/1464420715602441

Attaei M, Loureiro MV, Vale M, Condeço JAD, Pinho I, Bordado JC, Marques AC (2018) Isophorone diisocyanate (IPDI) microencapsulation for mono-component adhesives: effect of the active H and NCO sources. Polymers 10:825. https://doi.org/10.3390/polym10080825

Loureiro MV, Vale M, Schrijver AD, Bordado JC, Silva E, Marques AC (2018) Hybrid custom-tailored sol-gel derived microscaffold for biocides immobilization. Microporous Mesoporous Mater 261:252–258. https://doi.org/10.1016/j.micromeso.2017.10.056

Loureiro MV, Lourenço MJ, Schrijver AD, Santos LF, Bordado JC, Marques AC (2017) Effect of operation variables and monomers on the properties of polyamide microcapsules. J Mater Sci 52:5380–5389. https://doi.org/10.1007/s10853-017-0782-6

Loureiro MV, Ciriminna R, Lourenço MJ, Santos LF, Schrijver AD, Bordado JC, Pagliaro M, Marques AC (2017) Organically-modified silica based microspheres for self-curing polyurethane one component foams. Microporous Mesoporous Mater 244:244–250. https://doi.org/10.1016/j.micromeso.2016.10.039

Saunders K (1998) Organic polymer chemistry of adhesives, fibres, paints, plastics, and rubbers, 2nd edn. Chapman and Hall, London

Duan B (2016) in Handbook of encapsulation and controlled release. In: Karsa DR, Stephenson RA (eds) Microencapsulation via in situ polymerization. Woodhead Publishing Limited, Cambridge, pp 307–314

Haghayegh M, Mirabedini SM, Yeganeh H (2016) Microcapsules containing multi-functional reactive isocyanate-terminated polyurethane prepolymer as a healing agent. Part 1: synthesis and optimization of reaction conditions. J Mater Sci 51:3056–3068. https://doi.org/10.1007/s10853-015-9616-6

Ma Y, Jiang Y, Tan H, Zhang Y, Gu J (2017) A rapid and efficient route to preparation of isocyanate microcapsules. Polymers 7:24–27. https://doi.org/10.3390/polym9070274

Yang J, Keller MW, Moore JS, White SR, Sottos NR (2008) Microencapsulation of isocyanates for self-healing polymers. Macromolecules 41:9650–9655. https://doi.org/10.1021/ma801718v

Sondari D, Septevani AA, Randy A, Triwulandari E (2010) Polyurethane microcapsule with glycerol as the polyol component for encapsulated self healing agent. IJET 2:446–471

Di Credico DB, Griffini G, Levi M, Turri S (2013) Microencapsulation of a UV-responsive photochromic dye by means of novel UV-screening polyurea-based shells for smart coating applications. ACS Appl Mater Interfaces 5:6628–6634. https://doi.org/10.1021/am401328f

Kardar P (2015) Preparation of polyurethane microcapsules with different polyols component for encapsulation of isophorone diisocyanate healing agent. Prog Org Coat 89:271–276. https://doi.org/10.1016/j.porgcoat.2015.09.009

Ming Y, Hu J, Xing J, Wu M, Qu J (2016) Preparation of polyurea/melamine formaldehyde double-layered self-healing microcapsules and investigation on core fraction. J Microencapsul 33:307–314. https://doi.org/10.1080/02652048.2016.1178352

Huang M, Yang J (2011) Facile microencapsulation of HDI for self-healing anticorrosion coatings. J Mater Chem 21:11123–11130. https://doi.org/10.1039/C1JM10794A

Wu G, An J, Tang XZ, Xiang Y, Yang J (2014) A versatile approach towards multifunctional robust microcapsules with tunable, restorable, and solvent-proof superhydrophobicity for self-healing and self-cleaning coatings. Adv Func Mater 24:6751–6761. https://doi.org/10.1002/adfm.201401473

Nguyen L-TT, Hillewaere XKD, Teixeira RFA, Berg OVD, Prez FED (2014) Efficient microencapsulation of a liquid isocyanate with in situ shell functionalization. Polym Chem 6:1159–1170. https://doi.org/10.1039/C4PY01448K

Zhang M, Ni P, Yan N (1994) Effect of operation variables and monomers on the properties of polyamide microcapsules. J Microencapsul 12:425–435. https://doi.org/10.3109/02652049509087255

Hu M, Guo J, Yu Y, Cao L, Xu Y (2017) Research advances of microencapsulation and its prospects in the petroleum industry. Materials 10:369. https://doi.org/10.3390/ma10040369

Arnold R, Nelson J, Verbanc J (1957) Recent advances in isocyanate chemistry. Chem Rev 57:47–76. https://doi.org/10.1021/cr50013a002

McFarland B, Pojman JA (2015) Effects of shell crosslinking on polyurea microcapsules containing a free-radical initiator. J Appl Polym Sci 132:32. https://doi.org/10.1002/app.42408

Han H, Li S, Zhu X, Jiang X, Kong XZ (2014) One step preparation of porous polyurea by reaction of toluene diisocyanate with water and its characterization. RSC Adv 4:33520–33529. https://doi.org/10.1039/c4ra06383j

Verhoeven VWA, Padsalgikar AD, Ganzeveld KJ, Janssen LPBM (2006) A kinetic investigation of polyurethane polymerization for reactive extrusion purposes. J Appl Polym Sci 101:370–382. https://doi.org/10.1002/app.23848

Shi F, Deng Y (2005) Abnormal FT-IR and FTRaman spectra of ionic liquids confined in nano-porous silica gel. Spectrochimica ActaPart A Mol Biomol Spectrosc 62:239–244. https://doi.org/10.1016/j.saa.2004.12.031

Almeida RM, Marques AC (2018) Handbook of sol–gel science and technology: processing, characterization and applications. In: Klein L, Aparicio M, Jitianu A (eds) Characterization of sol-gel materials by infrared spectroscopy. Springer, BErlin, pp 1121–1151

Cesari A, Loureiro MV, Vale M, Yslas EI, Dardanelli M, Marques AC (2019) Polycaprolactone microcapsules containing citric acid and naringin for plant growth and sustainable agriculture: physico-chemical properties and release behavior. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2019.135548

Acknowledgements

This research was funded by FEDER through the COMPETE 2020 program and the Regional Operational Program of Lisbon—LISBOA2020, in the scope of the Portugal2020 Project 17930, “ECOBOND—Development of new ecological, self-reactive, monocomponent adhesives”. The authors gratefully acknowledge Fundação para a Ciência e a Tecnologia (FCT) through the support of CERENA (Strategic Project FCT-UID/ECI/04028/2019) and the Grants SFRH/BD/140700/2018 (Mónica V. Loureiro) and SFRH/BD/138717/2018 (Mário Vale).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

The supplementary file S1 shows the MCs size distribution bar chart, for each MCs’ sample. The value of the predominant MCs’ diameter value is provided in the main body of the manuscript. The distribution chart enables a clearer vision of the MCs’ size distribution. The supplementary file S2 shows the bar charts representing the NCO FTIR’ peaks narrowing and shifting effect for the encapsulated isocyanate species. These effects, as well as a hypothesis for these observations are explained in the main body of the manuscript. The FTIR peaks, used to draw the bar charts are also provided in the paper. The supplementary file 2 enables a clearer vision of the referred effect.

Rights and permissions

About this article

Cite this article

Loureiro, M.V., Attaei, M., Rocha, S. et al. The role played by different active hydrogen sources in the microencapsulation of a commercial oligomeric diisocyanate. J Mater Sci 55, 4607–4623 (2020). https://doi.org/10.1007/s10853-019-04301-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04301-1