Abstract

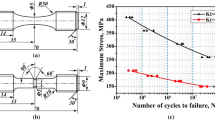

The effect of single overload on the fatigue crack growth in 2024-T3 and 7075-T6 Al alloys was analyzed. Fatigue tests under constant-amplitude loading with overload peak were carried out on V-notched specimens. Fractographic analysis was used as a principal approach to explain the crack growth retardation due to the overload. Scanning electron microscopy (SEM) analyses were conducted on the fractured surface of failed specimens to study the retardation effect. The obtained results show that the overload application generates a plastic zone in both aluminum alloys. The generated plastic zone is three times larger in the case of 2024-T3 compared to 7075-T6, and thus, a significant crack retardation was induced for 2024-T3. The retardation effect due to the overload for 2024-T3 and 7075-T6 lasted for about 10 mm and 1 mm, respectively, from the point of overload application.

Similar content being viewed by others

References

P. Dai, S. Li, and Z.H. Li, The effects of overload on the fatigue crack growth in ductile materials predicted by plasticity-corrected stress intensity factor, Eng. Fract. Mech., 111(2013), p. 26.

B.J.P. Belnoue, T.S. Jun, F. Hofmann, B. Abbey, and A.M. Korsunsky, Evaluation of the overload effect on fatigue crack growth with the help of synchrotron XRD strain mapping, Eng. Fract. Mech., 77(2010), No. 16, p. 3216.

A. Arcari and N.E. Dowling, Modeling mean stress relaxation in variable amplitude loading for 7075-T6511 and 7249-T76511 high strength aluminium alloys, Int. J. Fatigue, 42(2012), p. 238.

Z.Y. Ding, X.G. Wang, Z.L. Gao, and S.Y. Bao, An experimental investigation and prediction of fatigue crack growth under overload/underload in Q345R steel, Int. J. Fatigue, 98(2017), p. 155.

S.C. Li, Y.H. Zhang, L. Qi, and Y.L. Kang, Effect of single tensile overload on fatigue crack growth behavior in DP780 dual phase steel, Int. J. Fatigue, 106(2018), p. 49.

J. Saarimäki, J. Moverare, R. Eriksson, and S. Johansson, Influence of overloads on dwell time fatigue crack growth in Inconel718, Mater. Sci. Eng. A, 612(2014), p. 398.

S.M. Beden, S. Abdullah, A.K. Ariffin, and N.A. Al-Asady, Fatigue crack growth simulation of aluminium alloy under spectrum loadings, Mater. Des., 31(2010), No. 7, p. 3449.

S. Mikheevskiy, S. Bogdanov, and G. Glinka, Analysis of fatigue crack growth under spectrum loading — The UniGrow fatigue crack growth model, Theor. Appl. Fract. Mech., 79(2015), p. 25.

A. Albedah, S.M. Khan, B. Bouiadjra, and F. Benyahia, Fatigue crack propagation in aluminum plates with composite patch including plasticity effect, Proceedings of the Institution of Mechanical Engineers. Part G: Journal of Aerospace Engineering, 232(2017), No. 11, p. 2122.

B.B. Verma, A. Kumar, and P.K. Ray, Fatigue crack growth delay following overload, Trans. Indian Inst. Met., 53(2000), No. 6, p. 291.

A.J. McEvily, S. Ishikawa, and C. Makabe, The influence of the baseline R value on the extent of retardation after an overload, [in] Mechanism and Mechanics of Fracture: The John Knott Symposium, Columbus, 2002. p. 37.

C.M. Ward-Close, A.F. Blom, and R.O. Ritchie, Mechanisms associated with transient fatigue crack growth under variable-amplitude loading: An experimental and numerical study, Eng. Fract. Mech., 32(1989), No. 4, p. 613.

M.J. Doré and S.J. Maddox, Accelerated fatigue crack growth in 6082-T651 aluminium alloy subjected to periodic underloads, Procedia Eng., 66(2013), p. 313.

I.S. Putra and J. Schijve, Crack opening stress measurements of surface cracks in 7075-T6 Al alloy plate specimens through electron fractography, Fatigue Fract. Eng. Mater. Struct., 15(1992), p. 323.

M.N. James and A.E. Paterson, Fatigue performance of 6261-T6 aluminium alloy — constant and variable amplitude loading of parent plate and welded specimens, Int. J. Fatigue, 19(1997), No. 93, p. 109.

M. Benachour, A. Hadjoui, M. Benguediab, and N. Benachour, Effect of the amplitude loading on fatigue crack growth, Procedia Eng., 2(2010), No. 1, p. 121.

P.K. Liaw, T.R. Leax, and W.A. Logsdon, Near threshold fatigue crack growth behavior in metals, Acta Metall., 31(1983), No. 10, p. 1581.

K.W. Jones and M.L. Dunn, Fatigue crack growth through a residual stress field introduced by plastic beam bending, Fatigue Fract. Eng. Mater. Struct., 31(2008), No. 10, p. 863.

N. Ranganathan, Certain issues in variable amplitude fatigue, Procedia Eng., 101(2015), p. 404.

J. Schijve, The significance of fractography for investigations of fatigue crack growth under variable-amplitude loading, Fatigue Fract. Eng. Mater. Struct., 22(1999), p. 87.

J. Schijve, The application of small overloads for fractography of small fatigue cracks initiated under constantamplitude loading, Int. J. Fatigue, 70(2015), p. 63.

Annual Book of ASTM Standards, Standard A. E647: Standard Test Method for Measurement of Fatigue Crack Growth Rates, ASTM International, 2000, p. 628.

Y. Murakami, Stress Intensity Factors Handbook, Pergamon Press, Oxford, 1987, p. 9.

S. Datta, A. Chattopadhyay, N. Iyyer, and N. Phan, Fatigue crack propagation under biaxial fatigue loading with single overloads, Int. J. Fatigue, 109(2018), p. 103.

M. Skorupa, Load interaction effects during fatigue crack growth under variable amplitude loading — A literature review. Part I: empirical trends, Fatigue Fract. Eng. Mater. Struct., 21(1998), p. 987.

S.M.A.K. Mohammed, A. Albedah, F. Benyahia, and B.B. Bouiadjra, Effect of single tensile peak overload on the performance of bonded composite repair of cracked Al 2024- T3 and Al 7075-T6 plates, Compos. Struct., 193(2018), p. 260.

S.M.A.K. Mohammed, B.B. Bouiadjra, F. Benyahia, and A. Albedah, Analysis of the single overload effect on fatigue crack growth in AA 2024-T3 plates repaired with composite patch, Eng. Fract. Mech., 202(2018), p. 147.

T.W. Zhao, J.X. Zhang, and Y.Y. Jiang, A study of fatigue crack growth of 7075-T651 aluminum alloy, Int. J. Fatigue, 30(2008), No. 7, p. 1169.

Acknowledgement

The authors extend their appreciation to the Deanship of Scientific Research at King Saud University for funding the work through the research group (No. RGP-VPP-035).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Albedah, A., Bouiadjra, B.B., Mohammed, S.M.A.K. et al. Fractographic analysis of the overload effect on fatigue crack growth in 2024-T3 and 7075-T6 Al alloys. Int J Miner Metall Mater 27, 83–90 (2020). https://doi.org/10.1007/s12613-019-1896-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1896-4