Abstract

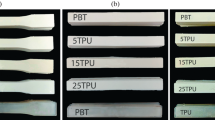

This study proposes using polypropylene grafted maleic anhydride (MA) to improve the interfacial compatibility between modified impact-resistant polypropylene (MPP) and thermoplastic polyurethane (TPU). The melt-compounding and injection method is used to prepare MPP/TPU/MA blends. The blending morphology, tensile behavior, flexural behavior, and impact behavior of blends are evaluated in terms of the content of TPU and MA. The SEM images show the positive influence of using MA on the compatibility between MPP and TPU, and only 1 wt% of it can efficiently decrease the difference in polarity and interfacial tension. As MA is an additional reinforcement, 100 wt% of the blends are made of MPP and TPU, indicating that more TPU means less MPP. When the blends are made of more TPU, the tensile strength of the control group (pure MPP/TPU blends) shows a decreasing trend. By contrast, MPP80/TPU20/MA3 blends have a tensile strength of 28 MPa and Young’s modulus of 927 MPa, while MPP90/TPU10/MA1 blends have the optimal flexural stress of 53.99 MPa and flexural modulus of 1493.61 MPa. Exception for MPP60/TPU40/MA1 blends, all the other experimental groups have greater impact strength as a result of using 1 wt% of MA. Specifically, MPP90/TPU10/MA1 blends have the maximum impact strength of 105.28 J/ m. The addition of MA has proven to efficiently improve the compatibility and interfacial adhesion between MPP and TPU, thereby forming an extraordinary bonding with a stabilized phase where a stress can be efficiently distributed. This study expects to design and adjust the performance of the composite blends according to the test results of SEM observation, tensile strength test, and impact strength test.

Similar content being viewed by others

References

Xiao JM, Chen YA (2015) New micro-structure designs of a polypropylene (PP) composite with improved impact property. Mater Lett 152:210–212

Liao J, Brosse N, Pizzi A, Hoppe S, Xi X, Zhou X (2019) Polypropylene blend with polyphenols through dynamic vulcanization: mechanical, rheological, crystalline, thermal, and UV protective property. Polymers (Basel) 11(7)

Su B, Zhou YG, Dong BB, Yan C (2019) Effect of compatibility on the foaming behavior of injection molded polypropylene and polycarbonate blend parts. Polymers (Basel) 11(2)

Guan Y, Wang S, Zheng A, Xiao H (2003) Crystallization behaviors of polypropylene and functional polypropylene. J Appl Polym Sci 88(4):872–877

Chow WS (2019) Polypropylene blends: properties control by design. In: Karger-Kocsis J, Bárány T (eds) Polypropylene handbook: morphology, blends and composites. Springer International Publishing, Cham, pp 419–480

Li TT, Chen AP, Hwang PW, Pan YJ, Hsing WH, Lou CW, Chen YS, Lin JH (2018) Synergistic effects of micro−/nano-fillers on conductive and electromagnetic shielding properties of polypropylene nanocomposites. Mater Manuf Process 33(2):149–155

Li Y, Li Y, Han CY, Yu YC, Xiao LG (2019) Morphology and properties in the binary blends of polypropylene and propylene-ethylene random copolymers. Polym Bull 76(6):2851–2866

Svab I, Pustak A, Denac M, Sever Skapin A, Leskovac M, Musil V, Smit I (2018) Polypropylene blends with m-EPR copolymers: mechanical and rheological properties. Acta Chim Slov 65(2):344–353

Ecaterina Matei MR, Andras ÁA, Predescu AM, Pantilimon C, Pica A, Predescu C (2017) Recycled polypropylene improved with thermoplastic elastomers. Int J Polym Sci 2017:1–10

Wang F, Wang J, He L, Nan F, Li HM, Jiang M, Wang JR, Yi JJ, Wang KF, Huang QG, Yang WT (2017) Preparation and characterization of nano-scaled composites of elastomeric ter-polypropylene blended with iPP through in-situ polymerization strategy. Mater Lett 209:64–67

Vakees E, Suresh J, Kayalvizhi M, Arun A, Karthik S (2016) Thermoplastic elastomers based on functionalized polystyrene with crystallizable diamide segment: synthesis and characterization. Adv Polym Technol 35(4):402–410

Lu YL, Yang Y, Xiao P, Feng YX, Liu L, Tian M, Li XL, Zhang LQ (2017) Effect of interfacial enhancing on morphology, mechanical, and rheological properties of polypropylene-ground tire rubber powder blends. J Appl Polym Sci 134(40)

Wang Z, Zhang T, Zhang Z, Ge Z, Luo Y (2016) Effect of hard-segment content on rheological properties of glycidyl azide polyol-based energetic thermoplastic polyurethane elastomers. Polym Bull 73(11):3095–3104

Naderi G, Ghoreishy MHR, Moradi M (2016) Effect of modified single-wall carbon nanotubes on mechanical and morphological properties of thermoplastic elastomer nanocomposites based on (polyamide 6)/(acrylonitrile butadiene rubber). J Vinyl Addit Technol 22(3):336–341

Kim TK, Kim BK, Lee SY, Cho YL, Kim MS, Jeong HM (2010) Thermoplastic polyurethane elastomer/thermoplastic polyolefin elastomer blends compatibilized with a polyolefinic segment in TPU. Macromol Res 18(2):177–184

Bovas BC, Karunamoorthy L, Chuan FB (2018) Effect of extrusion process melt temperature on polyurethane catheter surfaces. Mater Manuf Process 33(2):180–185

Kunchimon SZ, Tausif M, Goswami P, Cheung V (2019) Polyamide 6 and thermoplastic polyurethane recycled hybrid Fibres via twin-screw melt extrusion. J Polym Res 26(7)

Bulatovic VO, Mihaljevic A, Bajsic EG, Holjevac TG (2017) Morphology and thermal behavior of TPU/PP blends modified with maleic anhydride grafted SEBS-g-MA block copolymer. Int Polym Process 32(1):102–111

Doroudiani S, Park CB, Kortschot MT (1998) Processing and characterization of microcellular foamed high-density polyethylene/isotactic polypropylene blends. Polym Eng Sci 38(7):1205–1215

Bajsic EG, Filipan V, Bulatovic VO, Mandic V (2017) The influence of filler treatment on the mechanical properties and phase behavior of thermoplastic polyurethane/polypropylene blends. Polym Bull 74(8):2939–2955

Hato MJ, Motaung TE, Choi HJ, Scriba M, Khumalo VM, Malwela T (2017) Effect of organoclay on the properties of maleic anhydride-grafted polypropylene and poly(methyl methacrylate) blend. Polym Compos 38(3):431–440

La Mantia FP, Ceraulo M, Mistretta MC, Botta L, Morreale M (2018) Compatibilization of polypropylene/polyamide 6 blend fibers using photo-oxidized polypropylene. Materials (Basel) 12(1)

Petra Potschke KW, Fritsche H, Stutz H (1997) Morphology and properties of blends with different thermoplastic polyurethanes and polyolefines. J Appl Polym Sci 64(4):749–762

Bharathi Mariappan VR, Jaisankar SN (2014) Morphology and electrical conductivity of compatibilized thermoplastic polyurethane/single-walled carbon nanotube composites. Procedia Eng 93:59–65

Wang Y, Mi D, Delva L, Cardon L, Zhang J, Ragaert K (2018) New approach to optimize mechanical properties of the immiscible polypropylene/poly (ethylene terephthalate) blend: effect of shish-kebab and core-shell structure. Polymers (Basel) 10(10)

Lu QW, Macosko CW, Horrion J (2003) Compatibilized blends of thermoplastic polyurethane (TPU) and polypropylene. Macromol Symp 198:221–232

Monika PU, Chand N, Kumar V (2014) Effect of poly lactic acid on morphological, mechanical, and optical properties of compatibilized polypropylene and high density polyethylene blend. Compos Interface 21(2):133–141

Jeong JO, Lim YM, Park JS (2017) Improving thermal stability and mechanical performance of polypropylene/polyurethane blend prepared by radiation-based techniques. Eur Polym J 94:366–375

Kannan M, Bhagawan SS, Thomas S, Joseph K (2014) Studies on electrical properties of nanoclay filled thermoplastic polyurethane/polypropylene blends. Polym Compos 35(9):1671–1682

Aranburu N, Eguiazabal JI (2015) Improved mechanical properties of compatibilized polypropylene/polyamide-12 blends. Int J Polym Sci

dos Anjos EGR, Backes EH, Marini J, Pessan LA, Montagna LS, Passador FR (2019) Effect of LLDPE-g-MA on the rheological, thermal, mechanical properties and morphological characteristic of PA6/LLDPE blends. J Polym Res 26(6)

Jia S, Zhu Y, Wang Z, Chen L, Fu L (2015) Influences of PP-g-MA on the surface free energy, morphologies and mechanical properties of thermoplastic polyurethane / polypropylene blends. J Polym Res 22(8)

Song PA, Liu LN, Huang GB, Yu YM, Guo QP (2013) Largely enhanced thermal and mechanical properties of polymer nanocomposites via incorporating C-60@ graphene nanocarbon hybrid. Nanotechnology 24(50)

Bajsic EG, Smit I, Leskovac M (2007) Blends of thermoplastic polyurethane and polypropylene. I Mechanical and phase behavior. J Appl Polym Sci 104(6):3980–3985

Luo JS, Xu BP, Yu HW, Du YX, Feng YH (2015) Thermoplastic polyurethane/polypropylene blends in a co-rotating non-twin screws extruder. Fiber Polym 16(1):95–104

Yueyun Zhou LL, Liu W, Zeng G, Chen Y (2015) Preparation and characteristic of PC/PLA/TPU blends by reactive extrusion. Adv Mater Sci Eng 2015:1–10

Wang JS, Chen XD, Zhang NQ, Rong MZ (2006) Polyurethane/polyolefin blends: morphology, compatibilization and mechanical properties. Polym Polym Compos 14(1):1–11

Acknowledgements

The authors would especially like to thank Ministry of Science and Technology of Taiwan, for financially supporting this research under Contract MOST 107-2632-E-035-001 and MOST 107-2221-E-035-052-MY2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lin, T.A., Lin, MC., Lin, JY. et al. Modified polypropylene/ thermoplastic polyurethane blends with maleic-anhydride grafted polypropylene: blending morphology and mechanical behaviors. J Polym Res 27, 34 (2020). https://doi.org/10.1007/s10965-019-1974-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1974-3