Abstract

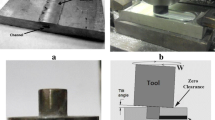

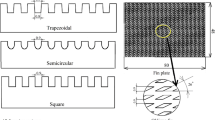

Integral mini-channels fabricated in the metal substrate by friction stir channeling process are different from conventional mini-channels due to irregular shape, and large surface roughness. The effect of axial wall conduction on heat transfer in such mini-channels is significant, which could limit their utilisation as cooling channels in heat transfer based applications. Hence, in this study, we present an experimental analysis of the thermo-hydraulic performance of a friction stir channel to identify the axial wall conduction effect using de-ionized water as working fluid. The thermo-hydraulic performance parameters are analysed in the range of Reynolds number of 500 to 2100. The local wall temperature distribution along the length of the mini-channel is found to be non-uniform due to the significant axial wall conduction effect. The distinct pattern of numerical heat flux distribution is used as evidence to confirm the presence of axial wall conduction effect which is implied by the local wall temperature distribution. The higher average heat transfer and flow characteristics compared to the theoretical predictions for conventional mini-channels are observed as a result of simultaneously developing flow and the presence of surface roughness.

Similar content being viewed by others

Abbreviations

- A c :

-

Average mini-channel cross-section area (m2)

- A s :

-

Heated side mini-channel surface area (m2)

- A w :

-

Average wall cross-section area (m2)

- c p :

-

Specific heat capacity (J/kg.K)

- D h :

-

Hydraulic diameter (m)

- f :

-

Darcy friction factor

- H ch :

-

Average mini-channel height (m)

- h g :

-

Heat transfer coefficient at glass wool surface (W/m2.K)

- I :

-

Current supply (A)

- i, j :

-

Index notations

- K :

-

Thermal conductivity (W/m.K)

- k :

-

Turbulent kinetic energy (J/kg)

- K f :

-

Thermal conductivity of fluid (W/m.K)

- K w :

-

Thermal conductivity of wall material (W/m.K)

- L c :

-

Mini-channel length (m)

- L h :

-

Hydrodynamically developing length (m)

- L t :

-

Thermally developing length (m)

- \( \dot{m} \) :

-

Mass flow rate (kg/s)

- Nu :

-

Nusselt number

- Nu avg :

-

Average Nusslet number

- Nu x :

-

Local Nusselt number

- P :

-

Electric DC power supply (W)

- \( \overline{P} \) :

-

Time averaged pressure (Pa)

- ΔP :

-

Pressure drop (Pa)

- P c :

-

Average mini-channel perimeter (m)

- Pe :

-

Peclet number

- Pr :

-

Prandtl number

- Pr t :

-

Turbulent prandtl number

- Po :

-

Poiseuille number

- q :

-

Heat transfer rate (W)

- q conv :

-

Convective heat transfer rate (W)

- q loss :

-

Heat loss (W)

- Re :

-

Reynolds number

- T :

-

Temperature (°C)

- \( \overline{T} \) :

-

Time averaged temperature (°C)

- T amb :

-

Ambient temperature (°C)

- T f :

-

Bulk fluid temperature (°C)

- T g :

-

Glass wool surface temperature (°C)

- T in :

-

Inlet fluid temperature (°C)

- T out :

-

Outlet fluid temperature (°C)

- T w :

-

Wall temperature (°C)

- T wx :

-

Local wall temperature along the mini-channel length (°C)

- μ :

-

Dynamic viscosity (Pa.s)

- \( \overline{u} \) :

-

Time averaged velocity component (m/s)

- \( \overset{\hbox{'}}{u} \) :

-

Fluctuation in velocity component (m/s)

- μ t :

-

Turbulent/ eddy viscosity (Pa.s)

- ν t :

-

Kinematic eddy viscosity (m2/s)

- V :

-

Voltage supply (V)

- v :

-

Bulk flow velocity (m/s)

- W ch :

-

Average mini-channel width (m)

- x :

-

Axial distance from the mini-channel entrance (m)

- x + :

-

Non-dimensional axial distance (x/ReDh)

- X + :

-

Non-dimensional axial distance (x/ReDhPr)

- ε :

-

Rate of dissipation of turbulent kinetic energy (m2/s3)

- ν :

-

Kinematic viscosity of fluid (m2/s)

- ρ :

-

Fluid density (kg/m3)

- α :

-

Aspect ratio of mini-channel

- ω :

-

Specific rate of dissipation of turbulent kinetic energy (1/s)

References

Kandlikar SG (2012) History, advances, and challenges in liquid flow and flow boiling heat transfer in microchannels: a critical review. J Heat Transf 134:034001–034015. https://doi.org/10.1115/1.4005126

Stone KM (1996) Review of literature on heat transfer enhancement in compact heat exchangers. University of Illinois

Kandlikar SG, Colin S, Peles Y et al (2013) Heat transfer in microchannels—2012 status and research needs. J Heat Transf 135:091001–091015. https://doi.org/10.1115/1.4024354

Mei F, Parida PR, Jing J et al (2008) Fabrication, assembly, and testing of Cu- and Al-based microchannel heat exchangers. J Microelectromech Syst 17:869–881. https://doi.org/10.1109/JMEMS.2008.924276

Mishra RS (2005) Integral channel in metal components and fabrication US patent 6923:362

Balasubramanian N, Mishra RS, Krishnamurthy K (2009) Friction stir channeling: characterization of the channels. J Mater Process Technol 209:3696–3704. https://doi.org/10.1016/j.jmatprotec.2008.08.036

Ferraz M (2012) Friction stir channeling industrial applications. Technical Universty of Lisboan

Rashidi A, Mostafapour A, Salahi S, Rezazadeh V (2013) Modified friction stir channeling : a novel technique for fabrication of friction Stir Channel. In: Applied mechanics and materials. Trans Tech Publications, Switzerland, 365–370

Vidal C, Infante V, Vilaça P (2013) Metallographic characterization of friction stir channels. In: Materials science forum. Trans Tech Publications, Switzerland, 817–822

Pandya S, Mishra RS, Arora A (2019) Channel formation during friction stir channeling process — a material flow study using X-ray micro-computed tomography and optical microscopy. J Manuf Process 41:48–55. https://doi.org/10.1016/j.jmapro.2019.03.021

Rashidi A, Mostafapour A (2015) Influence of tool pin geometry and moving paths of tool on channel formation mechanism in modified friction stir channeling technique. Int J Adv Manuf Technol 80:1087–1096. https://doi.org/10.1007/s00170-015-7049-7

Shen H, Xie G, Wang C (2019) Heat transfer and thermodynamic analysis by introducing multiple alternation structures into double-layer microchannel heat sinks. Int J Therm Sci 145:105975. https://doi.org/10.1016/j.ijthermalsci.2019.105975

Li X, Wang S, Wang X, Wang T (2019) Selected porous-ribs design for performance improvement in double-layered microchannel heat sinks. Int J Therm Sci 137:616–626. https://doi.org/10.1016/j.ijthermalsci.2018.12.029

Wang S, Li X, Wang X, Lu G (2018) Flow and heat transfer characteristics in double-layered microchannel heat sinks with porous fins. Int Commun Heat Mass Transfer 93:41–47. https://doi.org/10.1016/j.icheatmasstransfer.2018.03.003

Shen H, Zhang Y, Wang C, Xie G (2018) Comparative study for convective heat transfer of counter-flow wavy double-layer microchannel heat sinks in staggered arrangement. Appl Therm Eng 137:228–237. https://doi.org/10.1016/j.applthermaleng.2018.03.089

Tingzhen M, Cunjin CAI, Wei Y et al (2018) Optimization of dimples in microchannel heat sink with impinging jets—Part B: the influences of dimple height and arrangement optimization of dimples in microchannel heat sink with impinging jets. J Therm Sci 27:1–10. https://doi.org/10.1007/s11630-018-1019-y

Shen H, Wang C, Xie G (2018) A parametric study on thermal performance of microchannel heat sinks with internally vertical bifurcations in laminar liquid flow. Int J Heat Mass Transf 117:487–497. https://doi.org/10.1016/j.ijheatmasstransfer.2017.10.025

Lin L, Zhao J, Lu G et al (2017) Heat transfer enhancement in microchannel heat sink by wavy channel with changing wavelength/amplitude. Int J Therm Sci 118:423–434. https://doi.org/10.1016/j.ijthermalsci.2017.05.013

Balasubramanian N, Krishnamurthy K, Mishra RS (2007) Preliminary study of pressure drop and heat transfer through a friction Stir Channel. ASME 2007 international mechanical engineering congress and exposition. 933–939

Moharana MK, Agarwal G, Khandekar S (2011) Axial conduction in single-phase simultaneously developing flow in a rectangular mini-channel array. Int J Therm Sci 50:1001–1012. https://doi.org/10.1016/j.ijthermalsci.2011.01.017

Mishan Y, Mosyak A, Pogrebnyak E, Hetsroni G (2007) Effect of developing flow and thermal regime on momentum and heat transfer in micro-scale heat sink. Int J Heat Mass Transf 50:3100–3114. https://doi.org/10.1016/j.ijheatmasstransfer.2006.12.003

Caney N, Marty P, Bigot J (2007) Friction losses and heat transfer of single-phase flow in a mini-channel. Appl Therm Eng 27:1715–1721. https://doi.org/10.1016/j.applthermaleng.2006.07.019

Shen S, Xu JL, Zhou JJ, Chen Y (2006) Flow and heat transfer in microchannels with rough wall surface. Energy Convers Manag 47:1311–1325. https://doi.org/10.1016/j.enconman.2005.09.001

Gao P, Stéphane L, Favre-marinet M (2002) Scale effects on hydrodynamics and heat transfer in two-dimensional mini and microchannels. Int J Therm Sci 41:1017–1027

Maranzana G, Perry I Maillet D (2004) Mini-and micro-channels: influence of axial conduction in the walls 47:3993–4004. https://doi.org/10.1016/j.ijheatmasstransfer.2004.04.016

Duryodhan VS, Singh A, Singh SG, Agrawal A (2015) Convective heat transfer in diverging and converging microchannels. Int J Heat Mass Transf 80:424–438. https://doi.org/10.1016/j.ijheatmasstransfer.2014.09.042

Iztok T, Hetsroni G, Mavko B et al (2004) Effect of axial conduction on the heat transfer in micro-channels. Int J Heat Mass Transf 47:2551–2565. https://doi.org/10.1016/j.ijheatmasstransfer.2004.01.008

Zhuo L, He Y-L, Gui-Hua T, Wen-Quan T (2007) Experimental and numerical studies of liquid flow and heat transfer in microtubes. Int J Heat Mass Transf 50:3447–3460. https://doi.org/10.1016/j.ijheatmasstransfer.2007.01.016

Cole KD, Barbaros Ç (2011) The effect of axial conduction on heat transfer in a liquid microchannel flow. Int J Heat Mass Transf 54:2542–2549. https://doi.org/10.1016/j.ijheatmasstransfer.2011.02.007

Rahimi M, Mehryar R (2012) Numerical study of axial heat conduction effects on the local Nusselt number at the entrance and ending regions of a circular microchannel. Int J Therm Sci 59:87–94. https://doi.org/10.1016/j.ijthermalsci.2012.04.017

Fedorov AG, Viskanta R (2000) Three-dimensional conjugate heat transfer in the microchannel heat sink for electronic packaging. Int J Heat Mass Transf 43:399–415

Gamrat G, Favre-marinet M, Asendrych D (2005) Conduction and entrance effects on laminar liquid flow and heat transfer in rectangular microchannels. Int J Heat Mass Transf 48:2943–2954. https://doi.org/10.1016/j.ijheatmasstransfer.2004.10.006

Lin T, Kandlikar SG (2012) A theoretical model for axial heat conduction effects during single-phase flow in microchannels. J Heat Transf 134:020902-1–6. https://doi.org/10.1115/1.4004936

Kandlikar SG, Grande WJ, Grande WJ (2010) Evolution of microchannel flow passages—thermohydraulic performance and fabrication technology. Heat Transfer Eng 24(1):3–17. https://doi.org/10.1080/01457630304040

Qu W, Mudawar I (2002) Experimental and numerical study of pressure drop and heat transfer in a single-phase micro-channel heat sink. Int J Heat Mass Transf 45:2549–2565

Dirker J, Meyer JP, Garach DV (2014) Inlet flow effects in micro-channels in the laminar and transitional regimes on single-phase heat transfer coefficients and friction factors. Int J Heat Mass Transf 77:612–626. https://doi.org/10.1016/j.ijheatmasstransfer.2014.05.048

Mehta B, Khandekar S (2012) Infra-red thermography of laminar heat transfer during early thermal development inside a square mini-channel. Exp Thermal Fluid Sci 42:219–229. https://doi.org/10.1016/j.expthermflusci.2012.05.007

Shah RK, London AL (1978) Laminar flow forced convection in ducts. Academic, New York

Kandlikar S, Garimella S, Li D et al (2005) Heat transfer and fluid flow in minichannels and microchannels. Elsevier, Oxford

Wilcox DC (1998) Turbulence modeling for CFD, vol 2. DCW Industries, Inc, La Canada

Taylor J (1997) Introduction to error analysis, the study of uncertainties in physical measurements. University Science Books, New York

Attalla M, Maghrabie HM, Specht E (2016) An experimental investigation on fluid flow and heat transfer of rough mini-channel with rectangular cross section. Exp Thermal Fluid Sci 75:199–210. https://doi.org/10.1016/j.expthermflusci.2016.01.019

Mala GM, Li D (1999) Flow characteristics of water in microtubes. Int J Heat Fluid Flow 20:142–148

Li Z (2010) Experimental study on flow characteristics of liquid in circular microtubes. Microscale Thermophys Eng 7:253–265. https://doi.org/10.1080/10893950390219083

Celata GP, Cumo M, McPhail S, Zummo G (2006) Characterization of fluid dynamic behaviour and channel wall effects in microtube. Int J Heat Fluid Flow 27:135–143. https://doi.org/10.1016/j.ijheatfluidflow.2005.03.012

Morini GL (2004) Single-phase convective heat transfer in microchannels: a review of experimental results. Int J Therm Sci 43:631–651. https://doi.org/10.1016/j.ijthermalsci.2004.01.003

Acknowledgments

The authors would like to thank Government Engineering College, Patan-384265, Gujarat, India for the financial support under TEQIP-II Initiative (MHRD, Govt. of India). Authors acknowledge Prof. Amit Agrawal, Department of Mechanical Engineering, Indian Institute of Technology Bombay, Mumbai- 400076, India, for providing support for this study. One of the authors would like to acknowledge the Board of Research in Nuclear Sciences (BRNS), (project number 57/14/05/2019-BRNS/).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pandya, S., Gurav, S., Hedau, G. et al. Effect of axial conduction in integral rough friction stir channels: experimental thermo-hydraulic characteristics analyses. Heat Mass Transfer 56, 1725–1738 (2020). https://doi.org/10.1007/s00231-019-02788-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02788-7