Abstract

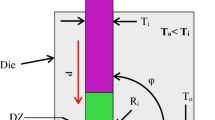

Newly developed severe plastic deformation (SPD) method TWO-CAP was applied to AA5083 to increase its mechanical properties. The method was developed to obtain the structural beams which have a thin-walled open-cross section area in high strength to weight ratio. During the TWO-CAP process, the annealed U-profile specimens will be pressed along the specifically designed die channel with the help of the hydraulic press machine. After the expansion and narrowing processes, the specimen leaves the die with initial dimensions at the end of each pass. Therefore, the material gains strength, hardness, and toughness while the microstructure of the material was improved as a result of the SPD. In order to determine the effect of the TWO-CAP on the mechanical properties of the material, the hardness and tension tests were carried out on the all passed specimens. Also, the characteristic investigations were performed on the specimens by using optical microscopy, SEM–EDS, and XRD analyses.

Graphic Abstract

Similar content being viewed by others

References

R.Z. Valiev, Superior strength in ultrafine-grained materials produced by SPD processing. Mater. Trans. 55, 13–18 (2014). https://doi.org/10.2320/matertrans.MA201325

P.W. Bridgman, Effects of high shearing stress combined with high hydrostatic pressure. Phys. Rev. 48, 825–847 (1935). https://doi.org/10.1103/PhysRev.48.825

V.M. Segal, The method of material preparation for subsequent working. Pat USSR 575892, 330 (1977)

J. Huang, Y.T. Zhu, D.J. Alexander, X. Liao, T.C. Lowe, R.J. Asaro, Development of repetitive corrugation and straightening. Mater. Sci. Eng. A 371, 35–39 (2004). https://doi.org/10.1016/S0921-5093(03)00114-X

H. Pirgazi, A. Akbarzadeh, R. Petrov, L. Kestens, Microstructure evolution and mechanical properties of AA1100 aluminum sheet processed by accumulative roll bonding. Mater. Sci. Eng., A 497, 132–138 (2008). https://doi.org/10.1016/j.msea.2008.06.025

M. Richert, H.P. Stüwe, M.J. Zehetbauer, J. Richert, R. Pippan, C. Motz, E. Schafler, Work hardening and microstructure of AlMg5 after severe plastic deformation by cyclic extrusion and compression. Mater. Sci. Eng. A 355, 180–185 (2003). https://doi.org/10.1016/S0921-5093(03)00046-7

H. Kaya, M. Uçar, A. Cengiz, R. Samur, D. Özyürek, A. Çalişkan, Novel molding technique for ECAP process and effects on hardness of AA7075. Mechanika 20, 5–10 (2014). https://doi.org/10.5755/j01.mech.20.1.4207

K. Özbeyaz, H. Kaya, A. Kentli, M. Şahbaz, S. Öğüt, Mechanical properties and electrical conductivity performance of ECAP processed AA2024 alloy. Indian J. Chem. Technol. 26, 266–269 (2019)

M. Şahbaz, H. Kaya, A. Kentli, M. Uçar, S. Öğüt, K. Özbeyaz, Experimental comparison of Al5083 alloy subjected to annealing and equal-channel angular pressing. Int J Comput Exp Sci Eng 5, 52–55 (2019). https://doi.org/10.22399/IJCESEN.394542

M. Şahbaz, H. Kaya, A. Kentli, M. Uçar, S. Öğüt, K. Özbeyaz, Analytical and numerical analysis comparison of equal channel angular pressing for Al5083 alloy. Adv. Sci. Eng. Med. 11, 1100–1103 (2019). https://doi.org/10.1166/asem.2019.2461

R. Gupta, S. Srivastava, N.K. Kumar, S.K. Panthi, High leaded tin bronze processing during multi-directional forging: effect on microstructure and mechanical properties. Mater. Sci. Eng. A (2016). https://doi.org/10.1016/j.msea.2015.12.068

Y. Beygelzimer, D. Orlov, V. Varyukhin, A new severe plastic deformation method: Twist extrusion, TMS Annual Meeting (Wiley, Hoboken, 2002), pp. 297–304

G. Faraji, A. Babaei, M. Mosavi Mashadi, K. Abrinia, Parallel tubular channel angular pressing (PTCAP) as a new severe plastic deformation method for cylindrical tubes. Mater. Lett. 77, 82–85 (2012). https://doi.org/10.1016/j.matlet.2012.03.007

A. Zangiabadi, M. Kazeminezhad, Development of a novel severe plastic deformation method for tubular materials: tube Channel Pressing (TCP). Mater. Sci. Eng. A 528, 5066–5072 (2011). https://doi.org/10.1016/j.msea.2011.03.012

Şahbaz M (2019) Development of a novel severe plastic deformation method for a thin-walled open section beam: thin-walled open channel angular pressing (TWO-CAP). PhD Dissertation, Marmara University

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, T.G. Langdon, Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scr. Mater. 35, 143–146 (1996). https://doi.org/10.1016/1359-6462(96)00107-8

E.J. Hearn, Theories of Elastic Failure. Mech. Mater. 1, 401–429 (1997). https://doi.org/10.1016/B978-075063265-2/50016-5

S.Y. Chang, Ahn B. Du, S.K. Hong, S. Kamado, Y. Kojima, D.H. Shin, Tensile deformation characteristics of a nano-structured 5083 Al alloy. J. Alloys. Compd. 386, 197–201 (2005). https://doi.org/10.1016/j.jallcom.2004.03.148

M. Popovic, B. Verlinden, Microstructure and mechanical properties of Al-4 4 wt.%Mg alloy (AA5182) after equal channel angular pressing. Mater. Sci. Technol. 21, 606–612 (2005). https://doi.org/10.1179/174328405X38320

E.O. Hall, The deformation and ageing of mild steel: III discussion of results. Proc Phys Soc Sect B 64, 747–753 (1951). https://doi.org/10.1088/0370-1301/64/9/303

N. Petch, The cleavage strength of polycrystals. J. Iron Steel Inst. 173, 25–28 (1953)

N.H. Heo, Y.U. Heo, S.K. Kwon, N.J. Kim, S.J. Kim, H.C. Lee, Extended hall-petch relationships for yield, cleavage and intergranular fracture strengths of bcc steel and its deformation and fracture behaviors. Met. Mater. Int. 24, 265–281 (2018). https://doi.org/10.1007/s12540-018-0026-6

E. Bagherpour, N. Pardis, M. Reihanian, R. Ebrahimi, An overview on severe plastic deformation: research status, techniques classification, microstructure evolution, and applications. Int. J. Adv. Manuf. Technol. 100, 1647–1694 (2019)

K. Edalati, Review on recent advancements in severe plastic deformation of oxides by high-pressure torsion (HPT). Adv. Eng. Mater. 21, 1800272 (2019)

K.T. Park, S.H. Myung, D.H. Shin, C.S. Lee, Size and distribution of particles and voids pre-existing in equal channel angular pressed 5083 Al alloy: their effect on cavitation during low-temperature superplastic deformation. Mater. Sci. Eng. A 371, 178–186 (2004). https://doi.org/10.1016/j.msea.2003.11.042

K.T. Park, J.H. Park, Y.S. Lee, W.J. Nam, Microstructures developed by compressive deformation of coarse grained and ultrafine grained 5083 Al alloys at 77 K and 298 K. Mater. Sci. Eng. A 408, 102–109 (2005). https://doi.org/10.1016/j.msea.2005.07.040

V. Uvarov, I. Popov, Metrological characterization of X-ray diffraction methods at different acquisition geometries for determination of crystallite size in nano-scale materials. Mater. Charact. 85, 111–123 (2013). https://doi.org/10.1016/j.matchar.2013.09.002

K.S. Suresh, N.P. Gurao, D.S. Singh, S. Suwas, K. Chattopadhyay, S.V. Zherebtsov, G.A. Salishchev, Effect of equal channel angular pressing on grain refinement and texture evolution in a biomedical alloy Ti13Nb13Zr. Mater. Charact. 82, 73–85 (2013). https://doi.org/10.1016/j.matchar.2013.05.003

G.K. Williamson, R.E. Smallman, III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye-Scherrer spectrum. Philos. Mag. 1, 34–46 (1956). https://doi.org/10.1080/14786435608238074

S. Takaki, T. Tsuchiyama, K. Nakashima, H. Hidaka, K. Kawasaki, Y. Futamura, Microstructure development of steel during severe plastic deformation. Met. Mater. Int. 10, 533–539 (2004). https://doi.org/10.1007/BF03027415

Acknowledgements

We would like to thank Prof. Dr. Mehmet UÇAR for his support in the laboratory studies. This study was funded by Marmara University, Commission of Scientific Research Project (FEN-C-DRP-120417-0183, FEN-P-141118-0602, and FEN-A-090217-0045). The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Şahbaz, M., Kentli, A. & Kaya, H. Performance of Novel TWO-CAP (Thin-Walled Open Channel Angular Pressing) Method on AA5083. Met. Mater. Int. 27, 2430–2437 (2021). https://doi.org/10.1007/s12540-019-00594-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00594-8