Abstract

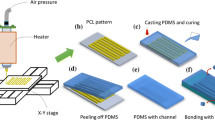

Micromilling is a flexible, inexpensive and rapid prototyping technique for polymer microfluidic devices. However, the applications of microfluidic devices fabricated by micromilling have been compromised by their poor surface quality. In this study, we demonstrated a gas-blowing-assisted (GBA) polydimethylsiloxane (PDMS) coating that is used to reduce the surface roughness of micromilled channels, yielding optical grade channel walls while simultaneously offering high flexibility in channel dimensions and morphology by controlling the coating parameters. In this method, a thin layer of PDMS is coated on the engraved substrate, and then a computer numerical control (CNC)-guided gas-blowing is used to selectively remove surplus PDMS prepolymer in channels, which results in a thin residual and smooth PDMS coating on the walls of channels. With this GBA PDMS coating, the channel surface roughness of below 8 nm could be achieved without the need of advanced polishing equipment or procedures. Furthermore, this method has the capability to fabricate non-rectangular microchannels with different shapes in cross-section depending on the process parameters, which benefits microvascular research and tissue engineering.

Similar content being viewed by others

References

Abdelgawad M, Wu C, Chien W-Y, Geddie WR, Jewett MA, Sun Y (2011) A fast and simple method to fabricate circular microchannels in polydimethylsiloxane (PDMS). Lab Chip 11:545–551

Ajdari A, Bontoux N, Stone HA (2006) Hydrodynamic dispersion in shallow microchannels: the effect of cross-sectional shape. Anal Chem 78:387–392

Alapan Y, Little JA, Gurkan UA (2014) Heterogeneous red blood cell adhesion and deformability in sickle cell disease. Sci Rep 4:7173

Alapan Y, Hasan MN, Shen R, Gurkan UA (2015) Three-dimensional printing based hybrid manufacturing of microfluidic devices. J Nanotechnol Eng Med 6:021007

Amin R et al (2016) 3D-printed microfluidic devices. Biofabrication 8:022001

Aramcharoen A, Sean KC, Kui L (2012) An experimental study of micromilling of polymer materials for microfluidic applications. Int J Abras Technol 5:286–298

Bartholomeusz DA, Boutte RW, Andrade JD (2005) Xurography: rapid prototyping of microstructures using a cutting plotter. J Microelectromech Syst 14:1364–1374

Carugo D, Lee JY, Pora A, Browning R, Capretto L, Nastruzzi C, Stride E (2016) Facile and cost-effective production of microscale PDMS architectures using a combined micromilling-replica moulding (μMi-REM) technique. Biomed Microdevices 18:4

Chan CY, Goral VN, Derosa ME, Huang TJ, Yuen PK (2014) A polystyrene-based microfluidic device with three-dimensional interconnected microporous walls for perfusion cell culture. Biomicrofluidics 8:046505

Chandrasekaran A, Kalashnikov N, Rayes RF, Wang C, Spicer J, Moraes C (2017) Thermal scribing to prototype plastic microfluidic devices, applied to study the formation of neutrophil extracellular traps. Lab Chip 17:2003–2012

Chen PC, Pan CW, Lee WC, Li KM (2014a) An experimental study of micromilling parameters to manufacture microchannels on a PMMA substrate. Int J Adv Manuf Technol 71:1623–1630

Chen PC, Pan CW, Lee WC, Li KM (2014b) Optimization of micromilling microchannels on a polycarbonate substrate. Int J Precis Eng Manuf 15:149–154

Cheng J-Y, Wei C-W, Hsu K-H, Young T-H (2004) Direct-write laser micromachining and universal surface modification of PMMA for device development. Sens Actuators B Chem 99(1):186–196

Cieslicki K, Piechna A (2009) Investigations of mixing process in microfluidic manifold designed according to biomimetic rule. Lab Chip 9:726–732

Duffy DC, Mcdonald JC, Schueller OJ, Whitesides GM (1998) Rapid prototyping of microfluidic systems in poly(dimethylsiloxane). Anal Chem 70:4974–4984

Fiddes LK, Raz N, Srigunapalan S, Tumarkan E, Simmons CA, Wheeler AR, Kumacheva E (2010) A circular cross-section PDMS microfluidics system for replication of cardiovascular flow conditions. Biomaterials 31:3459–3464

Floryan JM (2007) Three-dimensional instabilities of laminar flow in a rough channel and the concept of hydraulically smooth wall. Eur J Mech B Fluids 26:305–329

Futai N, Gu W, Takayama S (2004) Rapid prototyping of microstructures with bell-shaped cross-sections and its application to deformation-based microfluidic valves. Adv Mater 16:1320–1323

Guckenberger DJ, Groot TED, Wan A, Beebe DJ, Young EWK (2015) Micromilling: a method for ultra-rapid prototyping of plastic microfluidic devices. Lab Chip 15:2364–2378

Gutmann O et al (2004) A highly parallel nanoliter dispenser for microarray fabrication. Biomed Microdevices 6:131–137

Holbrough JL, Campbell JM, Meldrum FC, Christenson HK (2012) Topographical control of crystal nucleation. Cryst Growth Des 12(2):750–755

Hong T, Ju W, Wu MC, Tai C, Tsai C, Fu L (2010) Rapid prototyping of PMMA microfluidic chips utilizing a CO2 laser. Microfluid Nanofluid 9:1125–1133

Hupert ML, Guy WJ, Llopis SD, Shadpour H, Rani S, Nikitopoulos DE, Soper SA (2007) Evaluation of micromilled metal mold masters for the replication of microchip electrophoresis devices. Microfluid Nanofluid 3:1–11

James F, Leslie Y (2010) Fabrication of microfluidic devices using polydimethylsiloxane. Biomicrofluidics 4:3461

Kim BS, Lee KG, Choi HW, Lee TJ, Park KJ, Park JY, Lee SJ (2013) Facile fabrication of plastic template for three-dimensional micromixer-embedded microfluidic device. Biochip J 7:104–111

Ku X, Zhang Z, Liu X, Chen L, Li G (2018) Low-cost rapid prototyping of glass microfluidic devices using a micromilling technique. Microfluid Nanofluid 22:82

Lashkaripour A, Silva R, Densmore D (2018) Desktop micromilled microfluidics. Microfluid Nanofluid 22:31

Lopes R, Rodrigues RO, Pinho D, Garcia V, Schutte H, Lima R, Gassmann S (2015) Low cost microfluidic device for partial cell separation: micromilling approach. In: IEEE international conference on industrial technology, pp 3347–3350

Marco D et al (2013) Solvent vapor treatment controls surface wettability in PMMA; femtosecond-laser-ablated microchannels. Microfluid Nanofluid 14:171–176

Mcdonald JC, Duffy DC, Anderson JR, Chiu DT, Wu H, Schueller OJ, Whitesides GM (2015) Fabrication of microfluidic systems in poly(dimethylsiloxane). Polym Bull 21:27–40

Mohammed MI et al (2015) Improved manufacturing quality and bonding of laser machined microfluidic systems. Proc Technol 20:219–224

Ogilvie IRG, Sieben VJ, Floquet CFA, Zmijan R, Mowlem MC, Morgan H (2010) Reduction of surface roughness for optical quality microfluidic devices in PMMA and COC. J Micromech Microeng 20:065016

Prentner S, Allen DM, Larcombe L, Marson S, Jenkins K, Saumer M (2009) Effects of channel surface finish on blood flow in microfluidic devices. In: Design, test, integration & packaging of MEMS/MOEMS, 2009. MEMS/MOEMS '09. Symposium, pp 1091–1096

Rahmanian O, Devoe DL (2013) Pen microfluidics: rapid desktop manufacturing of sealed thermoplastic microchannels. Lab Chip 13:1102–1108

Sia SK, Whitesides GM (2010) Microfluidic devices fabricated in poly(dimethylsiloxane) for biological studies. Electrophoresis 24:3563–3576

Singhal J et al (2015) Blood flow visualization and measurements in microfluidic devices fabricated by a micromilling technique. Micro Nanosyst 7:148–153

Sinton D, Li D (2003) Electroosmotic velocity profiles in microchannels. Colloids Surf Physicochem Eng Aspects 222:273–283

Vecchione R, Pitingolo G, Guarnieri D, Falanga AP, Netti PA (2016) From square to circular polymeric microchannels by spin coating technology: a low cost platform for endothelial cell culture. Biofabrication 8:025005

Wang Z, Zheng HY, Lim RYH, Wang ZF, Lam YC (2011) Improving surface smoothness of laser-fabricated microchannels for microfluidic application. J Micromech Microeng 21:095008

Yazdi AA, Popma A, Wong WS, Nguyen T, Pan Y, Xu J (2016) 3D printing: an emerging tool for novel microfluidics and lab-on-a-chip applications. Microfluid Nanofluid 20:50

Yen DP, Ando Y, Shen KJT (2016) A cost-effective micromilling platform for rapid prototyping of microdevices. Technology 4:234–239

Yoshida E, Yoshimura Y, Uo M, Yoshinari M, Hayakawa T (2012) Influence of nanometer smoothness and fibronectin immobilization of titanium surface on MC3T3-E1 cell behavior. J Biomed Mater Res A 100:1556–1564

Acknowledgements

We would like to thank Mr. Xiong Zeng for his help in correcting the language of this article. This work was supported by grants from the National Natural Science Foundation of China (Nos. 61974012, 61771078 and 21827812), the Chongqing Research Program of Basic Research and Frontier Technology (No. cstc2017jcyjBX0036), the Chongqing Technical Innovation and Application Demonstration Program (No. cstc2018jscx-mszdX0073), and the National Postdoctoral Program for Innovative Talents (No. BX20190049).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, X., Dong, Z., Zhao, Q. et al. Optimization of micromilled channels for microfluidic applications using gas-blowing-assisted PDMS coating. Microfluid Nanofluid 24, 11 (2020). https://doi.org/10.1007/s10404-019-2315-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-019-2315-x