Abstract

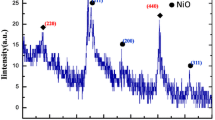

Fe-doped ZnO (Fe–ZnO) mesoporous nanoparticles have been synthesized via a facile hydrothermal method, which utilizes pluronic triblock copolymer polyethylene glycol–polypropylene glycol–polyethylene glycol (PEO-PPO-PEO) as the pore-forming agent. Fe–ZnO composites have an unique porous structure. Their pore sizes increase with Fe-doping concentration and reach a maximum as Fe concentration is 15 at.%; the specific surface area of synthesized mesoporous Fe–ZnO nanoparticles reaches a maximum as the Fe concentration is about 11 at.%. Electron microscopy, vapor pressure isotherm measurements and photoluminescence (PL) were used to characterize synthesized Fe–ZnO composites. Fe–ZnO-based gas sensors exhibit excellent response in detecting ethanol; the sensing response of Fe(11 at.%)–ZnO reaches 319.8, which is significantly higher than most of the ZnO-based gaseous sensors. The improved sensitivity is ascribed to the increase of oxygen-related defects and specific surface area of Fe–ZnO composites.

Similar content being viewed by others

References

X. Liu, G. Wang, A. Ng et al., Appl. Surf. Sci. 357, 2169–2175 (2015)

C.Y. Liu, H.Y. Xu, Y. Sun et al., OPT Express 22, 16731–16737 (2014)

S. Luo, Y. Shen, Z. Wu et al., Mater. Sci. Semicond. Process. 41, 535–543 (2016)

S. Park, S. Kim, H. Ko, C. Lee, J. Electro. Ceram. 33(1–2), 75–81 (2014)

Z.Q. Zheng, J.D. Yao, B. Wang, G.W. Yang, Sci. Rep. 5, 11070 (2015)

L. Zhu, Y. Li, W. Zeng, Appl. Surf. Sci. 427, 281–287 (2018)

F. Cao, C. Li, M. Li et al., Appl. Surf. Sci. 447, 173–181 (2018)

L. Wang, Y. Kang, X. Liu et al., Sens. Actuators B 162, 237–243 (2011)

C.T. Quy, C.M. Hung, N. Duy et al., J. Electron. Mater. 46, 3406–3411 (2017)

N. Saito, K. Watanabe, H. Haneda et al., J. Phys. Chem. C 122, 7353–7360 (2018)

K.C. Barick, S. Singh, M. Aslam, D. Bahadur, Microporous Mesoporous Mater. 134(1–3), 195–202 (2010)

N. Han, L. Chai, Q. Wang et al., Sens. Actuators B 147, 525–530 (2010)

G. He, M. Jiang, B. Li et al., J. Mater. Chem. C 5, 10938–10946 (2017)

A.B. Khatibani, M. Abbasi, J. Sol-Gel Sci. Technol. 86(2), 255–265 (2018)

Ganesh RS, Patil VL, Durgadevi E, et al. (2019) Chem. Phys. Lett. 136725***.

M. Boshta, E. Chikoidze, M. Sayed et al., J. Mater. Sci. Lett. 49, 7943–7948 (2014)

S. Chattopadhyay, T.K. Nath, A.J. Behan et al., J. Magn. Magn. Mater. 323, 1033–1039 (2011)

M.L. Dinesha, H.S. Jayanna, S. Ashoka, G.T. Chandrappa, J. Alloy Compd. 485(1–2), 538–541 (2009)

L. Zhang, B. Dong, L. Xu et al., Sens. Actuators B 252, 367–374 (2017)

V. Postica, I. Hölken, V. Schneider et al., Mater. Sci. Semicond. Process. 49, 20–33 (2016)

A. Khayatian, S. Safa, R. Azimirad et al., Physica E 84, 71–78 (2016)

Y. Shen, S. Luo, Z. Wu et al., J. Mater. Sci. 27, 12660–12668 (2016)

J. Tan, J. Chen, K. Liu, X. Huang, Sens. Actuators B 230, 46–53 (2016)

M.A.R. Miranda, J.M. Sasaki, Acta Crystallogr. A 74(1), 54–65 (2018)

S. Bai, T. Guo, Y. Zhao et al., Sens. Actuators B 195, 657–666 (2014)

S.T. Mun et al., J. Ceram. Soc. 119(1390), 517–521 (2011)

L. Luo, W. Tao, X. Hu et al., J. Power Sources 196, 10518–10525 (2011)

J. Liu, Y. Lu, X. Cui et al., Sens. Actuators B 248, 862–867 (2017)

X. Wang, Y. Zhang, C. Hao et al., Ind. Eng. Chem. Res. 53, 6585–6592 (2014)

Groen JC, Peffer LA, Pérez-Ramı́rez J (2003) Microporous Mesoporous Mater. 60(1–3), 1–17.

L. Zhang, J. Zhao, H. Lu et al., Sens. Actuators B 171, 1101–1109 (2012)

Z. Wen, L. Zhu, Z. Zhang, Z. Ye, Sens. Actuators 208, 112–121 (2015)

X. Li, J. Wei, J. Xu et al., J. Nanopart. Res. 19, 1–11 (2017)

F.J. Ren, X.B. Yu, Y.H. Ling, J.Y. Feng, Int. J. Min. Met. Mater. 19, 461–466 (2012)

J. Xu, S. Li, L. Li, L. Chen, Y. Zhu, Ceram. Int. 44(14), 16773–16780 (2018)

R. Vyas, P. Kumar, J. Dwivedi et al., RSC Adv. 4, 54953–54959 (2014)

S. Huang, T. Wang, Q. Xiao, J. Phys. Chem. Solids 76, 51–58 (2015)

A. Rambu, C. Doroftei, L. Ursu, F. Iacomi, J. Mater. Sci. Lett. 48, 4305–4312 (2013)

Y. Cai, H. Fan, M. Xu et al., Cryst. Eng. Commun. 15, 7339–7345 (2013)

S.Y. Seo, C.H. Kwak, S.H. Kim et al., J. Cryst. Growth 312, 2093–2097 (2010)

C. Zhao, C. Shao, X. Li et al., J. Alloy Compd. 747, 916–925 (2018)

N. Han, P. Hu, A. Zuo et al., Sens. Actuators B 145, 114–119 (2010)

O.M. Lemine, M. Bououdina, M. Sajieddine et al., Phys B 406, 1989–1994 (2011)

A. Silambarasu, A. Manikandan, K. Balakrishnan, J. Supercond. Nov. Magn. 30(9), 2631–2640 (2017)

A. Yu, J. Qian, H. Pan et al., Sens. Actuators B 158, 9–16 (2011)

A. Sahai, Y. Kumar, V. Agarwal et al., J. Appl. Phys. 116, 164315 (2014)

Funding

This funding was supported by National Natural Science Foundation of China (Grant No. 11775139, No.11375112), Shanghai City Committee of Science and Technology (Grant No. 15520500200), Water Resources Department of Guangdong Province (CN) (Grant No. XJ2016126) and UMKC’s Funding for Excellency grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shen, Y., Li, Q., Li, T. et al. Improved ethanol gas-sensing properties of optimum Fe–ZnO mesoporous nanoparticles. J Mater Sci: Mater Electron 31, 3074–3083 (2020). https://doi.org/10.1007/s10854-019-02852-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02852-2