Abstract

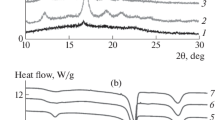

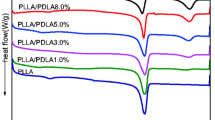

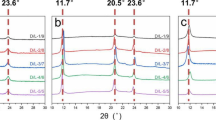

Blending of poly(l-lactide) and poly(d-lactide) (PLLA, PDLA) results in the formation of poly(lactide) stereocomplex crystallites (SC). For the preparation method, numerous reports employed solution mixing and stirring to receive a product with uniform performance. However, the effect of stirring time during solution mixing on the subsequent crystallization behavior did not clear yet, and which is important for solution crystallization, casting and spinning. In this paper, linear PLLA and PDLA with various molecular weights were synthesized. The PLLA and PDLA solutions were mixed together and stirred for different times before casting. Results revealed that the structures of PLA SC and homochiral crystallites (HC) did not vary with change in the stirring time. More amount of content of SC with uniform structure and less amount of content of HC were produced in the specimens stirred for longer time. When the specimens crystallized either from the melt or from the melt-quenching, less amount of content of crystallites (total crystallinity of SC and HC) was produced and the melting temperature of SC and HC depressed in the specimens that were stirred for longer time. With the increase in molecular weights, the effect of stirring time on the crystallization behaviors declined. This investigation provides a route to tailor the crystallization behavior of PLLA/PDLA specimens.

Similar content being viewed by others

References

Jem K J, van der Pol J, de Vos S (2010) Microbial lactic acid, its polymer poly(lactic acid), and their industrial applications. In: Chen GG-Q (ed) Plastics from bacteria, vol 14, 1st edn. Springer, Berlin, pp 323–346. https://doi.org/10.1007/978-3-642-03287-5_13

Saeidlou S, Huneault MA, Li H, Park CB (2012) Poly(lactic acid) crystallization. Prog Polym Sci 37:1657–1677

Jun S, Yan-Long L, Sheng X, Xin-Chao B, Jing-Ru S, Gao L, Chen XS, Hou HQ (2015) The stereocomplex formation and phase separation of PLLA/PDLA blends with different optical purities and molecular weights. Chin J Polym Sci 33:1–8. https://doi.org/10.1007/s10118-015-1715-y

Ikada Y, Jamshidi K, Tsuji H, Hyon SH (1987) Stereocomplex formation between enantiomeric poly(lactides). Macromolecules 20:904–906

Tsuji H, Ikada Y (1996) Crystallization from the melt of poly(lactide)s with different optical purities and their blends. Macromol Chem Phys 197:3483–3499

Tsuji H, Ikada Y (1993) Stereocomplex formation between enantiomeric poly(lactic acid)s 9. Stereocomplexation from the melt. Macromolecules 26:6918–6926

Wang L, Feng C, Zhou D, Shao J, Hou H, Li G (2018) The crystallization and phase transition behaviors of asymmetric PLLA/PDLA blends: from the amorphous state. Polym Cryst 1:e10006

Shao J, Xiang S, Bian X, Sun J, Li G, Chen X (2015) Remarkable melting behavior of PLA stereocomplex in linear PLLA/PDLA blends. Ind Eng Chem Res 54:2246–2253

Hu X, Shao J, Zhou D, Li G, Ding J, Chen X (2017) Microstructure and melting behavior of a solution-cast polylactide stereocomplex: effect of annealing. J Appl Polym Sci. https://doi.org/10.1002/app.44626

Okihara T, Tsuji M, Kawaguchi A, Katayama KL, Tsuji H, Hyon SH, Ikada Y (1991) Crystal structure of stereocomplex of poly(L-lactide) and poly(D-lactide). J Macromol Sci Part B Phys 30:119–140. https://doi.org/10.1080/00222349108245788

Tsuji H, Ikada Y (1999) Stereocomplex formation between enantiomeric poly(lactic acid)s. XI. Mechanical properties and morphology of solution-cast films. Polymer 40:6699–6708

Hirata M, Kimura Y (2008) Thermo mechanical properties of stereoblock poly(lactic acid)s with different PLLA/PDLA block compositions. Polymer 49:2656–2661

Karst D, Yang Y (2008) Effect of arrangement of L-lactide and D-lactide in poly[(L-lactide)-co-(D-lactide)] on its resistance to hydrolysis studied by molecular modeling. Macromol Chem Phys 209:168–174

Shao J, Sun J, Bian X, Cui Y, Li G, Chen X (2012) Investigation of poly(lactide) stereocomplexes: 3-armed poly(L-lactide) blended with linear and 3-armed enantiomers. J Phys Chem B 116:9983–9991

Biela T, Duda A, Penczek S (2006) Enhanced melt stability of star-shaped stereocomplexes as compared with linear stereocomplexes. Macromolecules 39:3710–3713

Liu Y, Sun J, Bian X, Feng L, Xiang S, Sun B, Chen Z, Li G, Chen X (2013) Melt stereocomplexation from poly(l-lactic acid) and poly(d-lactic acid) with different optical purity. Polym Degrad Stab 98:844–852

Bao RY, Yang W, Jiang WR, Liu ZY, Xie BH, Yang MB, Fu Q (2012) Stereocomplex formation of high-molecular-weight polylactide: a low temperature approach. Polymer 53:5449–5454

Liu Z, Fu M, Ling F, Sui G, Bai H, Zhang Q, Fu Q (2019) Stereocomplex-type polylactide with bimodal melting temperature distribution: toward desirable melt-processability and thermomechanical performance. Polymer 169:21–28

Purnama P, Kim SH (2009) Stereocomplex formation of high molecular weight polylactide using supercritical fluid. Macromolecules 43:1137–1142

Bai D, Liu H, Bai H, Zhang Q, Fu Q (2017) Low-temperature sintering of stereocomplex-type polylactide nascent powder: effect of crystallinity. Macromolecules 50:7611–7619

Bai D, Liu H, Bai H, Zhang Q, Fu Q (2016) Powder metallurgy inspired low-temperature fabrication of high-performance stereocomplexed polylactide products with good optical transparency. Sci Rep 6:20260

Fu M, Liu Z, Bai D, Ling F, Bai H, Zhang Q, Fu Q (2018) Low-temperature sintering of stereocomplex-type polylactide nascent powder: from compression molding to injection molding. Macromol Mater Eng 303:1800178

Deng S, Bai H, Liu Z, Zhang Q, Fu Q (2019) Toward supertough and heat-resistant stereocomplex-type polylactide/elastomer blends with impressive melt stability via in situ formation of graft copolymer during one-pot reactive melt blending. Macromolecules 52:1718–1730

Song Y, Zhang X, Yin Y, Zhang C, de Vos S, Wang R, Joziasse CAP, Liu G, Wang D (2016) Crystallization of equimolar poly(l-lactide)/poly(d-lactide) blend below the melting point of α crystals under shear. Eur Polym J 75:93–103

Song Y, Zhang XQ, Yin YA, de Vos S, Wang RY, Joziasse CAP, Liu GM, Wang DJ (2015) Enhancement of stereocomplex formation in poly(L-lactide)/poly(D-lactide) mixture by shear. Polymer 72:185–192

Bao RY, Yang W, Wei XF, Xie BH, Yang MB (2014) Enhanced formation of stereocomplex crystallites of high molecular weight poly(l-lactide)/poly(d-lactide) blends from melt by using poly(ethylene glycol). ACS Sustain Chem Eng 2:2301–2309

Bao RY, Yang W, Liu ZY, Xie BH, Yang MB (2015) Polymorphism of a high-molecular-weight racemic poly(l-lactide)/poly(d-lactide) blend: effect of melt blending with poly(methyl methacrylate). RSC Adv 5:19058–19066

Samuel C, Cayuela J, Barakat I, Muller AJ, Raquez JM, Dubois P (2013) Stereocomplexation of polylactide enhanced by poly(methyl methacrylate): improved processability and thermomechanical properties of stereocomplexable polylactide-based materials. ACS Appl Mater Interfaces 5:11797–11807

Fukushima K, Furuhashi Y, Sogo K, Miura S, Kimura Y (2005) Stereoblock poly(lactic acid): synthesis via solid-state polycondensation of a stereocomplexed mixture of poly(L-lactic acid) and poly(D-lactic acid). Macromol Biosci 5:21–29

Cao ZQ, Sun XR, Bao RY, Yang W, Xie BH, Yang MB (2016) Role of carbon nanotube grafted poly(l-lactide)-block-poly(d-lactide) in the crystallization of poly(l-lactic acid)/poly(d-lactic acid) blends: suppressed homocrystallization and enhanced stereocomplex crystallization. Eur Polym J 83:42–52

Xiong ZJ, Zhang XQ, Wang R, de Vos S, Wang RY, Joziasse CAP, Wang DJ (2015) Favorable formation of stereocomplex crystals in poly(l-lactide)/poly(d-lactide) blends by selective nucleation. Polymer 76:98–104

Han L, Pan P, Shan G, Bao Y (2015) Stereocomplex crystallization of high-molecular-weight poly(l-lactic acid)/poly(d-lactic acid) racemic blends promoted by a selective nucleator. Polymer 63:144–153

He S, Bai H, Bai D, Ju Y, Zhang Q, Fu Q (2019) A promising strategy for fabricating high-performance stereocomplex-type polylactide products via carbon nanotubes-assisted low-temperature sintering. Polymer 162:50–57

Chen Y, Hua WQ, Zhang ZC, Xu JZ, Bian FG, Zhong GJ, Xu L, Li ZM (2019) An efficient, food contact accelerator for stereocomplexation of high-molecular-weight poly(l-lactide)/poly(d-lactide) blend under nonisothermal crystallization. Polymer 170:54–64

Shao J, Guo Y, Xiang S, Zhou D, Bian X, Sun J, Li G, Hou H (2016) The morphology and spherulite growth of PLA stereocomplex in linear and branched PLLA/PDLA blends: effects of molecular weight and structure. CrystEngComm 18:274–282

Shao J, Sun J, Bian X, Cui Y, Zhou Y, Li G, Chen X (2013) Modified PLA homochiral crystallites facilitated by the confinement of PLA stereocomplexes. Macromolecules 46:6963–6971

Shao J, Sun J, Bian X, Zhou Y, Li G, Chen X (2013) The formation and transition behaviors of the mesophase in poly(D-lactide)/poly(L-lactide) blends with low molecular weights. CrystEngComm 15:6469–6476

Tsuji H, Ikada Y, Hyon SH, Kimura Y, Kitao T (1994) Stereocomplex formation between enantiomeric poly(lactic acid). VIII. Complex fibers spun from mixed solution of poly(D-lactic acid) and poly(L-lactic acid). J Appl Polym Sci 51:337–344

Tsuji H (2005) Poly(lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol Biosci 5:569–597

Tsuji H, Nakano M, Hashimoto M, Takashima K, Katsura S, Mizuno A (2006) Electrospinning of poly(lactic acid) stereocomplex nanofibers. Biomacromol 7:3316–3320

Lv R, Tian R, Na B, Zhang P, Liu Q (2015) Strong confinement effects on homocrystallization by stereocomplex crystals in electrospun polylactide fibers. J Phys Chem B 119:15530–15535

Kyotani M (1982) Stirring-induced crystallization of nylon 6. J Macromol Sci B 21:275–285

Pennings AJ, Kiel AM (1965) Fractionation of polymers by crystallization from solution, III. On the morphology of fibrillar polyethylene crystals grown in solution. Kolloid Z Z Polym 205:160–162

Pennings AJ (1967) Fractionation of polymers by crystallization from solutions. II. J Polym Sci Polym Symp 16:1799–1812

Keller A, Willmouth FM (1972) Lattice orientation within stirring-induced crystals of polyethylene. J Macromol Sci B 6:539–544

Tsuji H, Hyon SH, Ikada Y (1991) Stereocomplex formation between enantiomeric poly(lactic acid)s. 4. Differential scanning calorimetric studies on precipitates from mixed solutions of poly(D-lactic acid) and poly(L-lactic acid). Macromolecules 24:5657–5662

Zhang JM, Tashiro K, Tsuji H, Domb AJ (2007) Investigation of phase transitional behavior of poly(L-lactide)/poly(D-lactide) blend used to prepare the highly-oriented stereocomplex. Macromolecules 40:1049–1054

Brzeziński M, Bogusławska M, Ilčíková M, Mosnáček J, Biela T (2012) Unusual thermal properties of polylactides and polylactide stereocomplexes containing polylactide-functionalized multi-walled carbon nanotubes. Macromolecules 45:8714–8721

Sun JR, Yu HY, Zhuang XL, Chen XS, Jing XB (2011) Crystallization behavior of asymmetric PLLA/PDLA blends. J Phys Chem B 115:2864–2869

Bouapao L, Tsuji H (2009) Stereocomplex crystallization and spherulite growth of low molecular weight poly(L-lactide) and poly(D-lactide) from the melt. Macromol Chem Phys 210:993–1002

Tsuji H, Bouapao L (2012) Stereocomplex formation between poly(L-lactic acid) and poly(D-lactic acid) with disproportionately low and high molecular weights from the melt. Polym Int 61:442–450

Tsuji H, Horii F, Hyon SH, Ikada Y (1991) Stereocomplex formation between enantiomeric poly(lactic acid)s. 2. Stereocomplex formation in concentrated solutions. Macromolecules 24:2719–2724

Tsuji H, Hyon SH, Ikada Y (1991) Stereocomplex formation between enantiomeric poly(lactic acid)s. 3. Calorimetric studies on blend films cast from dilute solution. Macromolecules 24:5651–5656

Saeidlou S, Huneault MA, Li HB, Sammut P, Park CB (2012) Evidence of a dual network/spherulitic crystalline morphology in PLA stereocomplexes. Polymer 53:5816–5824

Wei XF, Bao RY, Cao ZQ, Yang W, Xie BH, Yang MB (2014) Stereocomplex crystallite network in asymmetric PLLA/PDLA blends: formation, structure, and confining effect on the crystallization rate of homocrystallites. Macromolecules 47:1439–1448

He Y, Xu Y, Wei J, Fan ZY, Li SM (2008) Unique crystallization behavior of poly(L-lactide)/poly(D-lactide) stereocomplex depending on initial melt states. Polymer 49:5670–5675

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grants Nos. 51403089 and 21574060), the Major Special Projects of Jiangxi Provincial Department of Science and Technology (Grant No. 20114ABF05100), the Project of Jiangxi Provincial Department of Education (GJJ170229), the Technology Plan Landing Project of Jiangxi Provincial Department of Education (GCJ2011-243), the Outstanding Youth Foundation of Jiangxi Normal University, the China Postdoctoral Science Foundation (2019M652282), and Postdoctoral Science Foundation of Jiangxi Province (2018KY37).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shao, J., Xu, L., Pu, S. et al. The crystallization behavior of poly(l-lactide)/poly(d-lactide) blends: effect of stirring time during solution mixing. Polym. Bull. 78, 147–163 (2021). https://doi.org/10.1007/s00289-020-03103-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03103-9