Abstract

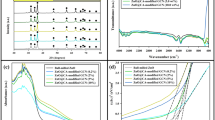

In this work, mesoporous CdS (130.7 m2/g) was prepared; then, ZnS was deposited by chemical bath deposition (CBD) and successive ionic layer adsorption and reaction (SILAR) method, to get CdS–ZnS(C) and CdS–ZnS(S), respectively. Subsequently, the highest efficient binary hybrid was sensitized with polyaniline to produce CdS–ZnS–PANI for the first time. XRD and EDX analyses confirmed the coating of CdS with ZnS using CBD and SILAR method. The careful examination for the surface morphology of the binary hybrids illustrated that CdS–ZnS(S) has uniform morphology and the CdS nanoparticles are homogeneously overcoated with ZnS. In contrast, CdS–ZnS(C) exhibits inhomogeneous surface, where there are ZnS particles that aggregate together and there is another region which contains ZnS deposited onto CdS. The estimated band gap of CdS, CdS–ZnS(S), and CdS–ZnS–PANI was 2.36 eV, 2.44 eV, and 1.9 eV, respectively. The removal efficiency for cationic and anionic dyes single and/or in combination using CdS, ZnS, CdS–ZnS(C), CdS–ZnS(S), PANI, and CdS–ZnS–PANI was studied. The effect of the amount of ZnS loaded by SILAR process on the activity of the CdS–ZnS(S) was presented. The results proposed that CdS–ZnS(S) exhibits selective adsorption and high removal efficiency for cationic dye compared to CdS–ZnS(C) due to higher negative zeta potential and large surface area. The CdS–ZnS–PANI ternary nanocomposite showed uptake efficiency of 96.7% for cationic dye (MB) and 94.3% for anionic dye (MO) in a mixed dye solution after 10 min. Finally, the possible adsorption mechanism was proposed.

Graphic abstract

Similar content being viewed by others

References

T. Hu, Z. Li, L. Lu, K. Dai, J. Zhang, R. Li, C. Liang, J. Colloid Interface Sci. 555, 166 (2019)

T. Hu, K. Dai, J. Zhang, G. Zhu, C. Liang, Appl. Surf. Sci. 481, 1385 (2019)

X. Ke, K. Dai, G. Zhu, J. Zhang, C. Liang, Appl. Surf. Sci. 481, 669 (2019)

K. Dai, J. Lv, J. Zhang, G. Zhu, L. Geng, C. Liang, ACS Sustain. Chem. Eng. 6, 12817 (2018)

Y. Huo, J. Zhang, K. Dai, Q. Li, J. Lv, G. Zhu, C. Liang, Appl. Catal. B Environ. 241, 528 (2019)

F. Mei, K. Dai, J. Zhang, W. Li, C. Liang, Appl. Surf. Sci. 488, 151 (2019)

Z. Li, X. Wang, J. Zhang, C. Liang, L. Lu, K. Dai, Chin. J. Catal. 40, 326 (2019)

Y. Huo, Z. Wang, J. Zhang, C. Liang, K. Dai, Appl. Surf. Sci. 459, 271 (2018)

Y. Huo, Y. Yang, K. Dai, J. Zhang, Appl. Surf. Sci. 481, 1260 (2019)

Y. Cheng, L. An, F. Gao, G. Wang, X. Li, X. Chen, Res. Chem. Intermed. 39, 3969 (2013)

A. Ahmad, S.H. Mohd-Setapar, S.C. Chuo, A. Khatoon, W.A. Wani, R. Kumar, M. Rafatullah, RSC Adv. 5, 30801 (2015)

M. Liu, X. Li, Y. Du, R. Han, Bioresour. Technol. Rep. 5, 238 (2019)

X. Chen, F. Zhang, Q. Wang, X. Han, X. Li, J. Liu, H. Lin, F. Qu, Dalton Trans. 44, 3034 (2015)

J.Y. Luo, Y.R. Lin, B.W. Liang, Y.D. Li, X.W. Mo, Q.G. Zeng, RSC Adv. 5, 100898 (2015)

H. Han, H. Lu, X. Jiang, F. Zhong, X. Ai, H. Yang, Y. Cao, Electrochim. Acta 301, 352 (2019)

S. Manjunatha, T. Machappa, Y.T. Ravikiran, B. Chethan, A. Sunilkumar, Phys. B Condens. Matter. 561, 170 (2019)

K. Pandiselvi, S. Thambidurai, Colloids Surf. B Biointerfaces 108, 229 (2013)

A. Olad, R. Nabavi, J. Hazard. Mater. 147, 845 (2007)

L. Kumar, I. Rawal, A. Kaur, S. Annapoorn, Sens. Actuators, B 240, 408 (2017)

B.H. Patil, K. Jang, S. Lee, J.H. Kim, C.S. Yoon, J. Kim, D.H. Kim, H. Ahn, J. Alloys Compd. 694, 111 (2017)

C. Zhou, M. Hong, Y. Yang, N. Hu, Z. Zhou, L. Zhang, Y. Zhang, Appl. Surf. Sci. 484, 663 (2019)

D. Mahanta, G. Madras, S. Radhakrishnan, S. Patil, J. Phys. Chem. B 113, 2293 (2009)

R. Kumar, M.O. Ansari, A.M. Barakat, Ind. Eng. Chem. Res. 53, 7167 (2014)

W. Yao, C. Shen, Y. Lu, Compos. Sci. Technol. 87, 8 (2013)

P. Xiong, Q. Chen, M. He, X. Sun, X. Wang, J. Mater. Chem. 22, 17485 (2012)

C.V. Reddy, J. Shim, M. Cho, J. Phys. Chem. Solids 103, 209 (2017)

O. Amiri, S.M.H. Mashkani, M.M. Rad, F. Abdvali, Superlattices Microstruct. 66, 67 (2014)

M. Koneswaran, R. Narayanaswamy, Sens. Actuators, B 210, 811 (2015)

J. Su, T. Zhang, L. Wang, J. Shi, Y. Chen, Chin. J. Catal. 38, 489 (2017)

Y. Lu, Y. Song, F. Wang, Mater. Chem. Phys. 138, 238 (2013)

M.J. Chatterjee, A. Ghosh, A. Mondal, D. Banerjee, RSC Adv. 7, 36403 (2017)

H. Zeghioud, S. Lamouri, Z. Safidine, M. Belbachir, J. Serb. Chem. Soc. 80, 917 (2015)

H. Ali, N. Ismail, M.S. Amin, M. Mekewi, Front. Energy 12, 249 (2018)

A.T. Kuvarega, R.W.M. Krause, B.B. Mamba, J. Nanoparticle Res. 14, 776 (2012)

H. Cui, B. Li, Z. Li, X. Li, S. Xu, Appl. Surf. Sci. 455, 831 (2018)

A.H. Qusti, A.Y.S. Malkhasian, M. Abdel Salam, J. Mol. Liq. 255, 364 (2018)

Y. Chen, B. Zhai, Y. Liang, Y. Li, J. Li, J. Solid State Chem. 274, 32 (2019)

B.N. Patra, D. Majhi, J. Phys. Chem. B 119, 8154 (2015)

Acknowledgement

This work was supported by the National Research Centre (No. AR110908). The author thanks Prof. Zahra Saleh, Central Laboratories Network and The Centers of Excellence, NRC, for providing instrumental facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ali, H. Ternary system from mesoporous CdS–ZnS modified with polyaniline for removal of cationic and anionic dyes. Res Chem Intermed 46, 571–592 (2020). https://doi.org/10.1007/s11164-019-03968-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-019-03968-0