Abstract

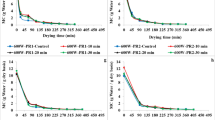

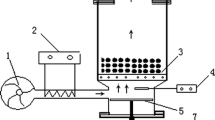

The experiments of contact ultrasound-assisted far-infrared radiation (FIR) drying on potato slices were conducted to investigate the effects of ultrasonic power on drying characteristics and quality properties. The results showed that contact ultrasound was helpful for accelerating mass transfer of the samples, and the improvement of ultrasonic power could significantly shorten drying time. The ultrasonic reinforcement effect on drying rate declined along with the decrease in moisture content. Deff values were within 1.15 × 10−10 and 1.96 × 10−10 m2/s, and improved with an increase in ultrasound power. Compared with FIR dried ones, more and larger pore size of microcapillaries in the samples’ tissue structure could be observed with contact ultrasound application, and higher ultrasonic power produced more microtunnels. Contact ultrasound in FIR drying could reduce the color difference of dried potato slices, and decrease the hardness and brittleness values. Higher TPC and TFC could be achieved as ultrasonic power increased.

Similar content being viewed by others

References

Bouayed J, Hoffmann L, Bohn T. Total phenolics, flavonoids, anthocyanins and antioxidant activity following simulated gastro-intestinal digestion and dialysis of apple varieties: Bioaccessibility and potential uptake. Food Chem. 128: 14-21 (2011)

Cárcel JA, García-Pérez JV, Riera E, Mulet A. Influence of high-intensity ultrasound on drying kinetics of persimmon. Dry. Technol. 25: 185-193 (2007)

Carlos ARJ, Byron DYV. Ultrasound as pretreatment to convective drying of Andean blackberry (Rubus glaucus Benth). Ultrason. Sonochem. 22: 205-210 (2015)

Chemat F, Huma Z, Khan MK. Applications of ultrasound in food technology: Processing, preservation and extraction. Ultrason. Sonochem. 18: 813-835 (2011)

Deng Y, Zhao Y. Effect of pulsed vacuum and ultrasound osmopretreatments on glass transition temperature, texture, microstructure and calcium penetration of dried apples (Fuji). LWT Food Sci. Technol. 41: 1575-1585 (2008)

Dujmić F, Brnčić M, Karlović S, Bosiljkov T, Ježek D, Tripalo B, Mofardin I. Ultrasound-assisted infrared drying of pear slices: Textural issues. J. Food Process Eng. 36: 397-406 (2013)

Fernandes FAN, Rodrigues S, García-Pérez JV, Cárcel JA. Effects of ultrasound-assisted air drying on vitamins and carotenoids of cherry tomatoes. Dry. Technol. 34: 986-996 (2015)

Gamboa-Santos J, Montilla A, Cárcel JA, Villamiel M, Garcia-Perez JV. Air-borne ultrasound application in the convective drying of strawberry. J. Food Eng. 128: 132-139 (2014)

Garcia-Perez JV, Puig A, Carcel JA, Perez-Munuera I. Enhancement of water transport and microstructural changes induced by high-intensity ultrasound application on orange peel drying. Food Bioprocess Tech. 5: 2256-2265 (2012)

Garcia-Perez JV, Puig A, Perez-Munuera I, Carcel JA, Riera E. Kinetic and microstructural changes induced by power ultrasound application on convective drying of eggplant. In: Proceedings of the 20th International Congress on Acoustics (ICA 2010). August, Sydney, Australia. pp. 23-27 (2010)

Kantrong H, Tansakul A, Mittal GS. Drying characteristics and quality of shiitake mushroom undergoing microwave-vacuum drying and microwave-vacuum combined with infrared drying. J. Food Sci. Technol. 51: 3594-3608 (2014)

Kek SP, Chin NL, Yusof YA. Direct and indirect power ultrasound assisted pre-osmotic treatments in convective drying of guava slices. Food Bioprod. Process. 91: 495-506 (2013)

Kim DO, Jeong SW, Lee CY. Antioxidant capacity of phenolic phytochemicals from various cultivars of plums. Food Chem. 81: 321-326 (2003)

Kim W-W, Ghimeray AK, Wu JC, Eom SH, Lee B-G, Kang W-S, Cho D-H. Effect of far infrared drying on antioxidant property, anti-inflammatory activity, and inhibitory activity in A549 cells of Gamguk (Chrysanthemum indicum L.) flower. Food Sci. Biotechnol. 21: 261-265 (2012)

Liu Y, Sun Y, Miao S, Li F, Luo D. Drying characteristics of ultrasound assisted hot air drying of Flos Lonicerae. J. Food Sci. Tech. 52: 4955-4964 (2015)

Liu Y, Sun Y, Yu H, Yin Y, Li X, Duan X. Hot air drying of purple-fleshed sweet potato with contact ultrasound assistance. Dry. Technol. 35: 564-576 (2016)

Liu Y, Wu J, Miao S, Chong C, Sun Y. Effect of a modified atmosphere on drying and quality characteristics of carrots. Food Bioprocess Tech. 7: 2549-2559 (2014)

Liu Y, Zeng Y, Wang Q, Sun C, Xi H. Drying characteristics, microstructure, glass transition temperature, and quality of ultrasound-strengthened hot air drying on pear slices. J Food Process. Preserv. 43: e13899 (2019)

Midilli A. Determination of pistachio drying behaviour and conditions in solar drying system. Int. J. Energ. Res. 25: 715-725 (2001)

Nowacka M, Wiktor A, Śledź M, Jurek N, Witrowa-Rajchert D. Drying of ultrasound pretreated apple and its selected physical properties. J. Food Eng. 113: 427-433 (2012)

Ortuño C, Pérez-Munuera I, Puig A, Riera E, Garcia-Perez JV. Influence of power ultrasound application on mass transport and microstructure of orange peel during hot air drying. Phys. Procedia. 3: 153-159 (2010)

Pawar SB, Pratape VM. Fundamentals of infrared heating and its application in drying of food materials: A review. J. Food Process Eng. 40: e12308 (2017)

Pei F, Shi Y, Mariga AM, Yang WJ, Tang XZ, Zhao LY, An XX, Hu QH. Comparison of freeze-drying and freeze-drying combined with microwave vacuum drying methods on drying kinetics and rehydration characteristics of button mushroom (Agaricus bisporus) slices. Food Bioprocess Tech. 7: 1629-1639 (2014)

Riadh MH, Ahmad SAB, Marhaban MH, Soh AC. Infrared Heating in food drying: An overview. Dry. Technol. 33: 322-335 (2015)

Riera E. Application of high-power ultrasound for dehydration of vegetables: Processes and devices. Dry. Technol. 25: 1893-1901 (2007)

Rodríguez Ó, Santacatalina JV, Simal S, Garcia-Perez JV, Femenia A, Rosselló C. Influence of power ultrasound application on drying kinetics of apple and its antioxidant and microstructural properties. J. Food Eng. 129: 21-29 (2014)

Ruiz Celma A, López-Rodríguez F, Cuadros Blázquez F. Experimental modelling of infrared drying of industrial grape by-products. Food Bioprod. Process. 87: 247-253 (2009)

Sabarez HT, Gallego-Juarez JA, Riera E. Ultrasonic-assisted convective drying of apple slices. Dry. Technol. 30: 989-997 (2012)

Salehi F, Kashaninejad M, Jafarianlari A. Drying kinetics and characteristics of combined infrared-vacuum drying of button mushroom slices. Heat Mass Transf. 53: 1751-1759 (2016)

Schössler K, Jäger H, Knorr D. Effect of continuous and intermittent ultrasound on drying time and effective diffusivity during convective drying of apple and red bell pepper. J. Food Eng. 108: 103-110 (2012)

Sun J, Zhao J, Fu D, Gu S, Wang D. Extraction, Optimization and antimicrobial activity of IWSP from oleaginous microalgae chlamydomonas sp YB-204. Food Sci. Technol. Res. 23: 819-826 (2017)

Tekin Z H, Baslar M. The effect of ultrasound-assisted vacuum drying on the drying rate and quality of red peppers. J. Therm. Anal. Calorim. 132: 1131-1143 (2018)

Vega-Gálveza A, Ah-Hen K, Chacana M, Vergara J, Martínez-Monzó J, García-Segovia P, Lemus-Mondaca R. Empirical modeling of drying process for apple (cv. Granny Smith) slices at different air temperatures. J. Food Process. Preserv. 32: 972-986 (2010)

Vega-Gálveza A, Ah-Hen K, Chacana M, Vergara J, Martínez-Monzó J, García-Segovia P, Lemus-Mondacaad R. Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chem. 132: 51-59 (2012)

Wiktor A, Sledz M, Nowacka M, Rybak K, Witrowa-Rajchert D. The influence of immersion and contact ultrasound treatment on selected properties of the apple tissue. Appl. Acoust. 103: 136-142 (2016)

Acknowledgements

The authors thank for the financial support from the College Innovation Talents Program of Henan (19HASTIT013), the Chinese College Students’ Innovative Training Program (201810464010) and Henan College Students’ Research Training Program (2018151).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xi, H., Liu, Y., Guo, L. et al. Effect of ultrasonic power on drying process and quality properties of far-infrared radiation drying on potato slices. Food Sci Biotechnol 29, 93–101 (2020). https://doi.org/10.1007/s10068-019-00645-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-019-00645-1