Abstract

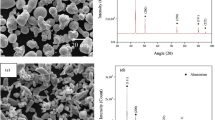

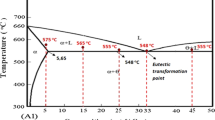

The present work investigates the microstructure development and mechanical properties of mechanically alloyed and hot-pressed copper (Cu)-X wt pct aluminum (Al) (X = 0, 3, 5, 10, 15) alloys. The morphology of the ball-milled Cu-Al powders changed from coarse flaky structure to small hard agglomerates with the addition of Al. It was observed that the density of Cu-Al samples varied between ~ 95 and 98 pct of theoretical density (ρth) after hot pressing (Temperature: 500 °C, Pressure: 500 MPa, Time: 30 min). The crystallite size of Cu-Al samples decreased for both the milled powders and hot-pressed samples. The XRD and SEM-EDS analyses of the hot-pressed samples confirmed the presence of α-Cu solid solution phases for the Cu alloyed with Al up to 5 wt pct. On the other hand, further addition of Al to Cu leads to the formation of both intermetallic compound (Cu9Al4) and solid solution phase. The nano-indentation tests indicated a significant increase in hardness (2.4 to 7.9 GPa) and elastic modulus (121.1 to 177.4 GPa) of Cu-Al alloys. The Cu-Al alloys were measured with very high compressive strength (813.8 to 1120.2 MPa) and the compressive strain varied in the range of 29.81 to 5.81 pct.

Similar content being viewed by others

References

1 H. Jang, K. Ko, S.J. Kim, R.H. Basch, and J.W. Fash: Wear, 2004, vol. 256, pp. 406–14.

2 H.M. Zaw, J.Y.H. Fuh, A.Y.C. Nee, and L. Lu: J. Mater. Process. Technol., 1999, vol. 89, pp. 182–6.

3 D. Prokoshkina, V.A. Esin, and S. V Divinski: Acta Mater., 2017, vol. 133, pp. 240–6.

4 M. Rabiee, H. Mirzadeh, and A. Ataie: J. Ultrafine Grained Nanostructured Mater., 2016, vol. 49, pp. 17–21.

A. Heidarzadeh and T. Saeid: Rare Met., 2016, vol. 35. pp. 1–11.

6 A.E. Nassef, A.I. Alateyah, M.A. El-Hadek, and W.H. El-Garaihy: Adv. Mater. Lett., 2017, vol. 8, pp. 717–22.

7 G.S. Jawaharram, S.J. Dillon, and R.S. Averback: J. Mater. Res., 2017, vol. 32, pp. 3156–64.

8 J. Guo, J. Rosalie, R. Pippan, and Z. Zhang: Scr. Mater., 2017, vol. 133, pp. 41–4.

J.R. Davis and A.S.M.I.H. Committee (2001) Copper and Copper Alloys, ASM International, Cleveland.

10 A. Korneva, B. Straumal, A. Kilmametov, R. Chulist, P. Straumal, and P. Zięba: Mater. Charact., 2016, vol. 114, pp. 151–6.

A.T. Vijayashakthivel, T.N. SrikanthaDath, and R. Krishnamurthy: Proc. Eng., 2014, vol. 97, pp. 56–63.

M.I. Latypov, E.Y. Yoon, D.J. Lee, R. Kulagin, Y. Beygelzimer, M. SeyedSalehi, and H.S. Kim: Metall. Mater. Trans. A 2014, vol. 45, pp. 2232–41.

13 S. Tamimi, M. Ketabchi, N. Parvin, M. Sanjari, and A. Lopes: Int. J. Met., 2014, vol. 2014, pp. 1–9.

14 W. Głuchowski, J. Stobrawa, Z. Rdzawski, and W. Malec: Mater. Sci. Forum, 2011, vol. 674, pp. 177–88.

15 Y.L. Gong, S.Y. Ren, S.D. Zeng, and X.K. Zhu: Mater. Sci. Eng. A, 2016, vol. 659, pp. 165–71.

16 H.S. Park, T. Kimura, T. Murakami, Y. Nagano, K. Nakata, and M. Ushio: Mater. Sci. Eng. A, 2004, vol. 371, pp. 160–9.

17 H. Wen, T.D. Topping, D. Isheim, D.N. Seidman, and E.J. Lavernia: Acta Mater., 2013, vol. 61, pp. 2769–82.

18 H. Wen and E.J. Lavernia: Scr. Mater., 2012, vol. 67, pp. 245–8.

19 J.-P. Kruth, P. Peeters, T. Smolderen, J. Bonse, T. Laoui, and L. Froyen: Rev. Int. CFAO dinformatique Graph., 1998, vol. 13, pp. 95–110.

20 J.-P. Kruth, P. Mercelis, J. Van Vaerenbergh, L. Froyen, and M. Rombouts: Rapid Prototyp. J., 2005, vol. 11, pp. 26–36.

21 F.A. Calvo, A. Ureng, J.M. Gomez De Salazar, and F. Molleda: J. Mater. Sci., 1988, vol. 23, pp. 2273–80.

Copper Development Association: Equilibrium Diagrams the Major Types of Phase Transformation, 1992.

23 C.Y. Chen and W.S. Hwang: Mater. Trans., 2007, vol. 48, pp. 1938–47.

24 L. Wu, L. Liu, J. Liu, and R. Zhang: Mater. Trans., 2012, vol. 53, pp. 504–7.

25 H.Y. Wang, Y. Chen, Y.W. Liu, F. Li, J.H. Liu, G.-R. Peng, and W.K. Wang: Chin. Phys. Lett., 2009, vol. 26, art. no. 106201.

26 D.S. Zhou, D.L. Zhang, C. Kong, and P. Munroe: Mater. Sci. Eng. A, 2013, vol. 584, pp. 67–72.

27 M.F. Giordana, N. Munoz-vasquez, M. Garro-gonzalez, and M.R. Esquivel: Procedia Mater. Sci., 2015, vol. 9, pp. 262–70.

28 R.H. Palma, A.H. Sepúlveda, R.A. Espinoza, and R.C. Montiglio: J. Mater. Process. Technol., 2005, vol. 169, pp. 62–6.

29 F. Wang, Y. Li, K. Yamanaka, K. Wakon, K. Harata, and A. Chiba: Mater. Des., 2014, vol. 64, pp. 441–9.

30 Y. Guo, G. Liu, H. Jin, Z. Shi, and G. Qiao: J. Mater. Sci., 2011, vol. 46, pp. 2467–73.

H. Baker, A.S.M. Handbook: Vol 3: Alloy Phase Diagrams, 1992. ASM International, Materials Park

32 Massalski T: Binary Alloy Phase Diagrams, AIP, Materials Park, Ohio, 1990.

V. Raghavan (2015) Physical Metallurgy: Principles and Practice. Third Edition. Prentice Hall India Pvt Limited, New Delhi

34 I. Cenoz: Metalurgija, 2010, vol. 16, pp. 115–22.

35 H.M. Otte: J. Appl. Phys., 1962, vol. 33, pp. 2892–3.

J.S. LlewelynLeach: J. Inst. Met., 1964, vol. 92, pp. 93–94.

L. Arnberg and S. Westman: Acta Crystallogr. Sect. A 1978, vol. 34, pp. 399–404.

38 V. Rajkovic, D. Bozic, and M.T. Jovanovic: Metalurgija, 2007, vol. 13, pp. 309–16.

39 W. He, E. Wang, L. Hu, Y. Yu, and H. Sun: J. Mater. Process. Technol., 2008, vol. 208, pp. 205–10.

40 A.S. Sharma, K. Biswas, B. Basu, and D. Chakravarty: Metall. Mater. Trans. A, 2011, vol. 42, pp. 2072–84.

41 A. Nassef and M. El-Hadek: Adv. Mater. Sci. Eng., 2016, vol. 53, pp. 38–42.

42 C. Martinez, F. Briones, P. Rojas, S. Ordonez, C. Aguilar, and D. Guzman: MRS Adv., 2017, vol. 2, pp. 2831–6.

A. KhorsandZak, W.H.A. Majid, M.E. Abrishami, and R. Yousefi: Solid State Sci., 2011, vol. 13, pp. 251–56.

V.D. Mote, Y. Purushotham, and B.N. Dole: J. Theor. Appl. Phys., 2012, vol. 6, art. no. 6.

45 S.F. Varol, G. Babur, G. Cankaya, and U. Kolemen: RSC Adv., 2014, vol. 4, pp. 56645–53.

46 T.D. Shen, R.B. Schwarz, and J.D. Thompson: Phys. Rev. B, 2005, vol. 72, art no. 14431.

47 A. Rohatgi, K.S. Vecchio, and I.G.T. Gray: Acta Mater., 2001, vol. 49, pp. 427–38.

48 Y.H. Zhao, Y.T. Zhu, X.Z. Liao, Z. Horita, and T.G. Langdon: Appl. Phys. Lett., 2006, vol. 89, art no. 121906.

49 Y.H. Zhao, J.F. Bingert, Y.T. Zhu, X.Z. Liao, R.Z. Valiev, Z. Horita, T.G. Langdon, Y.Z. Zhou, and E.J. Lavernia: Appl. Phys. Lett., 2008, vol. 92, art no. 81903.

50 G. Liu, J. Gu, S. Ni, Y. Liu, and M. Song: Mater. Charact., 2015, vol. 103, pp. 107–19.

51 F. Glas: Tribol. und Schmierungstechnik, 2005, vol. 52, pp. 55–63.

52 K. Biswas, A.S. Sharma, and B. Basu: Scr. Mater., 2013, vol. 69, pp. 122–6.

53 B.K. Prasad: Metall. Mater. Trans. A, 1997, vol. 28, pp. 809–15.

54 W.C. Oliver and G.M. Pharr: J. Mater. Res., 1992, vol. 7, pp. 1564–83.

55 R. Saha and W.D. Nix: Acta Mater., 2002, vol. 50, pp. 23–38.

56 D.M. Ebenstein and L.A. Pruitt: Nano Today, 2006, vol. 1, pp. 26–33.

L.L. Wu, L. Liu, M.S. Qi, J.H. Liu, R.J. Zhang (2012) Advanced Materials Research, vol. 562–564, Trans Tech Publications, Zurich, pp. 196–99.

P. Kucita, S.C. Wang, W.S. Li, R.B. Cook, M.J. Starink: J. Phys. Conf. Ser. vol. 644, 2015, art no. 12010.

59 K.S. Lee and K. Yong-Nam: Trans. Nonferrous Met. Soc. China, 2013, vol. 23, pp. 341–6.

60 J. Chen, Y.N. Shi, and K. Lu: J. Mater. Res., 2005, vol. 20, pp. 2955–9.

61 R.R. Chromik, R.P. Vinci, S.L. Allen, and M.R. Notis: J. Mater. Res., 2003, vol. 18, pp. 2251–61.

62 J.Y. Zhang, J.T. Zhao, X.G. Li, Y.Q. Wang, K. Wu, G. Liu, and J. Sun: Acta Mater., 2018, vol. 143, pp. 55–66.

63 F. Misjak, P.B. Barna, A.L. Toth, T. Ujvari, I. Bertoti, and G. Radnoczi: Thin Solid Films, 2008, vol. 516, pp. 3931–4.

64 B.J. Briscoe, L. Fiori, and E. Pelillo: J. Phys. D. Appl. Phys., 1998, vol. 31, p. 2395.

65 M.M. Shokrieh, M.R. Hosseinkhani, M.R. Naimi-Jamal, and H. Tourani: Polym. Test., 2013, vol. 32, pp. 45–51.

66 D. Beegan, S. Chowdhury, and M.T. Laugier: Surf. Coatings Technol., 2005, vol. 192, pp. 57–63.

67 S.-R. Jian, C.-H. Tasi, S.-Y. Huang, and C.-W. Luo: J. Alloys Compd., 2015, vol. 622, pp. 601–5.

68 B. Lauterbach and D. Gross: Mech. Mater., 1998, vol. 29, pp. 81–92.

69 E. van der Heide, E.D. Stam, H. Giraud, G. Lovato, N. Akdut, F. Clarysse, P. Caenen, and I. Heikillä: Wear, 2006, vol. 261, pp. 68–73.

Funding

Ministry of Human Resource and Development, Government of India is gratefully acknowledged for the financial support to procure hot press equipment under plan grants (Departmental Plan-Grant Funds Code No: P828) that is used in the present work.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 24, 2019.

Rights and permissions

About this article

Cite this article

Shaik, M.A., Golla, B.R. & Pitchuka, S.B. Processing and Characterization of Extremely Hard and Strong Cu-(0-15 wt pct)Al Alloys. Metall Mater Trans A 51, 708–724 (2020). https://doi.org/10.1007/s11661-019-05545-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05545-x