Abstract

In this paper, the gelation technique was utilized for the synthesis of a Si/Cu amorphous sample composed of oxygen, sodium, silicon, and copper. The obtained sample was identified utilizing FT-IR, EDS, XRD, and FE-SEM instruments. The non-crystalline nature of the obtained sample was confirmed through the presence of XRD broadband in the range 2θ = 16°–46°. Also, the obtained sample was utilized as an economically inexpensive and efficient adsorbent for the removal of methylene blue dye from aqueous media. Besides, several parameters were examined for evaluating the removal of methylene blue dye, for example, kinetic, equilibrium, thermodynamic, and reusability. Moreover, the Freundlich isotherm and pseudo-first-order kinetic model controlled the adsorption process. The maximum adsorption capacity of the obtained adsorbent was 102.05 mg/g. In addition, the negative ∆G° values affirmed the spontaneous properties of the adsorption. Also, the adsorption was exothermic and physical because ∆H° is negative and less than 40 kJ/mol. Finally, the obtained adsorbent was regenerated then reused several times without changing their removing efficiency.

Similar content being viewed by others

1 Introduction

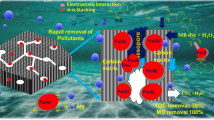

The expanding release of colorants such as dyes in the water is evaluated as one of the top genuine ecological issues. Most colorants are continuing and don't experience natural degradation, therefore causing a deterrent of the entry of light into the water and ruining the ecosystem [1, 2]. Many industries use methylene blue dye such as wood, silk, cotton, etc. It may achieve eye burns, thus causing perpetual eye damage in animals or humans. It can too prompt quick or troublesome breathing upon inhalation, similarly plentiful perspiring, burning sensation, nausea, vomiting, and mental disorders [3, 4]. Hence, the removal of colorants such as methylene blue dye from water is very important owing to their dangerous effects on the environment. Several methods are utilized for the removal of colorants from water for example membrane filtration, adsorption, ion exchange, chemical oxidation, electrochemical degradation, photocatalytic degradation, biological degradation, and ozonation [5,6,7,8,9,10,11,12,13,14,15]. Adsorption is viewed as one of the most dominant treatment techniques, in light of its prevalent effectiveness in the removal of a variety of colorants and besides, it is characterized by simplicity [16,17,18,19,20]. Various adsorbents such as Si/M, iron-based metal–organic framework, functionalized zirconium silicate, hydrogel beads, zeolite/chitosan composite, zeolite/activated carbon composite, zeolites, and magnetic graphene oxide are exceptionally powerful for the removal of colorants from aqueous media [21,22,23,24,25,26,27]. Looking for novel adsorbents that have a high capacity to bind with colorants molecules is a needful and required objective. Non-crystalline adsorbents, for example, Si/M and geopolymers have remarkable significance for water treatment because of their easy production and simple cost [21]. The literature confirmed that Si/M were fabricated using the gelation method via three steps. The first step is the dissolving of metal and silicon precursors. The second step is the production of –Si–O–M–O– units via condensation. The third step is the polycondensation for forming a gel [21]. Therefore, this paper aims to synthesize Si/Cu as a low-cost and efficient adsorbent for the removal of methylene blue dye from aqueous media. Also, the obtained adsorbent was identified utilizing FT-IR, EDS, XRD, and FE-SEM. Besides, several parameters were examined for evaluating the removal of methylene blue dye, for example, kinetic, equilibrium, thermodynamic, and reusability.

2 Experimental

2.1 Chemicals

The utilized chemicals in the current research were sodium metasilicate pentahydrate (Na2SiO3·5H2O), copper(II) chloride dihydrate (CuCl2·2H2O), hydrochloric acid (HCl), and sodium hydroxide (NaOH). These chemicals were bought from Sigma-Aldrich Company.

2.2 Synthesis of Amorphous Si/Cu Sample

0.02828 Mole silicon solution was prepared via dissolving 6.00 g of sodium metasilicate pentahydrate in 50 mL of distilled water. Also, a 0.01068 mole copper solution was prepared via dissolving 1.82 g of copper(II) chloride dihydrate in 50 mL of distilled water. Then, the copper solution was poured over the silicon solution drop by drop with continuous stirring for 1 h. After that, the formed gel was separated using filtration, washed a few times using distilled water, and dried at 105 °C for 20 h.

2.3 Utilization of Amorphous Si/Cu Sample for Removing Methylene Blue Dye from Aqueous Media

For getting the best time for removing methylene blue dye, the adsorption tests have been practiced as follows: 100 mg of the obtained Si/Cu sample was poured over 50 mL of 150 mg/L methylene blue dye solution then the blend was stirred at 600 rpm for different times. For getting the best pH for removing methylene blue dye, the adsorption tests have been practiced as follows: 100 mg of the obtained Si/Cu sample was poured over 50 mL of 150 mg/L methylene blue dye solution which was optimized to the desired pH using 0.1 M hydrochloric acid or sodium hydroxide then the blend was stirred for 1 h at 600 rpm. For getting the maximum adsorption capacity of the obtained Si/Cu sample, the adsorption tests have been practiced as follows: 100 mg of the obtained Si/Cu sample was poured over 50 mL of different concentrations of methylene blue dye which was optimized to pH 8. Then, the blend was stirred for 1 h at 600 rpm. For getting the best temperature for removing methylene blue dye, the adsorption tests have been practiced as follows: 100 mg of the obtained Si/Cu sample was poured over 50 mL of 150 mg/L methylene blue dye solution which was optimized to pH 8 then the blend was stirred at different temperatures for 1 h. The obtained Si/Cu sample was regenerated through the calcination of the loaded adsorbent at 300 °C for the elimination of the adsorbed dye. After that, 100 mg of the regenerated amorphous Si/Cu sample was poured over 50 mL of 150 mg/L methylene blue dye solution which was optimized to pH 8 then the blend was stirred for 1 h at 600 rpm. A previously constructed calibration curve utilizing a UV–Vis spectrophotometer was used for the estimation of methylene blue dye concentration. The wave number for the absorption measurement was 663 nm.

2.4 Physicochemical Measurements

The X-ray diffraction pattern of the obtained Si/Cu sample was gotten from 2θ = 2° to 80° utilizing an X-ray diffraction apparatus (Bruker, model D8, 18 kW diffractometer Advance) outfitted with monochromated Cu Kα radiation with wavelength equals 1.5419 Å with a scanning step of 0.02°/min. The FT-IR spectrum of the obtained Si/Cu sample was gotten using an FT-IR spectrophotometer (Perkin Elmer). K550X sputter coater was utilized for coating the obtained Si/Cu sample with gold then the morphology and elemental analysis were examined with FE-SEM microscope (Model Quanta) matched with an energy dispersive X-ray spectrometer EDS.

3 Results and Discussion

3.1 Characterization of Amorphous Si/Cu Sample

Figure 1a showed X-ray diffraction of the obtained Si/Cu sample. The non-crystalline properties of the obtained Si/Cu sample was confirmed through the presence of broadband in the range 2θ = 16°–46° [21].

Figure 2 showed energy dispersive X-ray spectroscopy of the obtained Si/Cu sample. The peaks at 0.93, 8.04, and 8.91 keV confirmed the presence of Cu Lα, Cu Kα, and Cu Kβ, respectively. Also, the peaks at 0.53, 1.04, and 1.74 keV confirmed the presence of O, Na, and Si, respectively. The mass percentages of Cu, Si, Na, and O were 54.22, 23.60, 4.98, and 17.20%, respectively. The presence of sodium in the sample is due to the compensation of negative charges which results due to the substitution of some Si4+ by Cu2+ ions. Hence, the expected formula of the obtained sample is Si4Cu4O5Na.

Figure 3 showed FT-IR of the obtained Si/Cu sample. T–O–T bending vibration (T = Si, Cu) was confirmed through the presence of a peak at 505 cm−1. Besides, the presence of peaks at 675 and 1017 cm−1 confirmed external and internal symmetric stretching vibrations of T–O–T, respectively. Moreover, the peaks at 1470 and 1650 cm−1 confirmed the external asymmetric stretching vibrations of T–O–T and bending vibration of adsorbed water, respectively. In addition, the peaks at 3537 cm−1 confirmed the stretching vibrations of adsorbed water [21, 28].

Figure 4 showed FE-SEM image of the obtained Si/Cu sample. The results confirmed the presence of irregular shapes.

3.2 Utilization of Amorphous Si/Cu Sample for Removing Methylene Blue Dye from Aqueous Media

% Removal of methylene blue dye (% R) was estimated utilizing Eq. (1) whereas the amounts of adsorbed methylene blue dye [Q (mg/g)] was estimated utilizing Eq. (2).

where Ce (mg/L) and Ci (mg/L) are the equilibrium and initial concentration of methylene blue dye, respectively. Also, V (L) and m (g) are the volume of methylene blue dye solution and mass of the obtained adsorbent, respectively.

3.2.1 Effect of Contact Time

Figure 5a clarified the relation of contact time against % R of methylene blue dye. % R at 5, 10, 20, 40, and 60 min were 19.90, 33.17, 46.59, 73.09, and 80.96, respectively. % R at longer times remains almost constant due to the saturation of active centers of the adsorbent.

Figure 5b clarified the relation of amount of adsorbed dye against contact time. Q at 5, 10, 20, 40, and 60 min were 14.93, 24.88, 34.95, 54.82, and 60.72 mg/g, respectively. Q at longer times remains almost constant due to the saturation of active centers of the adsorbent.

The time data was examined utilizing pseudo-first-order which was described utilizing Eq. (3) as clarified in Fig. 6a.

Also, the time data was examined utilizing pseudo-second-order which was described using [Eq. (4)] as clarified in Fig. 6b [29,30,31,32].

where K1 (L/min) and K2 (g/mg min) are the rate constant of pseudo-first-order and pseudo-second-order, respectively. Also, Qt (mg/g) and Qe (mg/g) are the amount of adsorbed dye at time t and equilibrium, respectively. The R2, Qe, and K1 constants of pseudo-first-order were 0.962, 67.07 mg/g, and 0.0586 ± 0.00289 L/min, respectively. Also, the R2, Qe, and K2 constants of pseudo-second-order were 0.949, 88.73 mg/g, and 0.0004 ± 0.03444 g/mg min, respectively. So, the adsorption process was controlled by the pseudo-first-order which possesses the highest R2 value.

3.2.2 Effect of pH

Figure 7a clarified the relation of pH against % R of methylene blue dye. % R at pH 2, 4, 6, and 8 were 19.77, 43.23, 81.33, and 83.33, respectively.

Figure 7b clarified the relation of pH against amount of adsorbed methylene blue dye. Q at pH 2, 4, 6, and 8 were 14.83, 32.42, 61.00, and 62.50 mg/g, respectively.

3.2.3 Effect of Concentration

Figure 8a clarified the relation of initial methylene blue concentration against % R of methylene blue dye. % R at initial concentration 90, 120, 150, and 180 mg/L were 93.84, 89.78, 83.33, and 80.37, respectively.

Figure 8b clarified the relation of initial methylene blue concentration against amount of adsorbed methylene blue dye. Q at initial concentration 90, 120, 150, and 180 mg/L were 42.23, 53.87, 62.50, and 72.33 mg/g, respectively.

The equilibrium data was examined utilizing Langmuir isotherm which was described utilizing Eq. (5) as clarified in Fig. 9a.

Also, the equilibrium data was examined utilizing Freundlich isotherm which was described utilizing Eq. (6) as clarified in Fig. 9b [29,30,31,32].

where KL (L/mg) and KF (mg/g) are the constant of Langmuir and Freundlich, respectively. Also, 1/n is the heterogeneity factor. Besides, Qm (mg/g) is the Langmuir maximum adsorption capacity. Moreover, Freundlich maximum adsorption capacity (Omf, mg/g) was calculated using Eq. (7).

The R2, Qm, and KL constants of Langmuir were 0.9840, 82.37 mg/g, and 0.163 L/mg, respectively. Also, the R2, Qmf, and KF constants of Freundlich were 0.9842, 102.05 mg/g, and 26.33 mg/g, respectively. So, the adsorption process was controlled by Freundlich isotherm which possesses the highest R2 value.

3.2.4 Effect of Temperature

Figure 10a clarified the relation of temperature against % R of methylene blue dye. % R at 298, 308, 318, and 328 K were 83.33, 76.67, 68.00, and 56.67, respectively.

Figure 10b clarified the relation of temperature against amount of adsorbed methylene blue dye. Q at 298, 308, 318, and 328 K were 62.50, 57.50, 51.00, and 42.50 mg/g, respectively.

The distribution coefficient (Kd, L/g) was determined utilizing Eq. (8) [29,30,31,32].

Also, the thermodynamic parameters were examined using Eqs. (9) and (10).

where R (kJ/mol K) and T (K) are gas constant and temperature, respectively. Also, ΔS° (kJ/mol K) and ΔH° (kJ/mol) are change in the entropy and enthalpy, respectively. Besides, ΔG° (kJ/mol) is change in free energy.

Figure 11 clarified the relation of ln Kd against 1/T. Hence, Table 1 contains the calculated ∆H°, ∆G°, and ∆S° thermodynamic parameters. The negative ∆G° values affirmed the spontaneous properties of the adsorption. Also, the adsorption was exothermic and physical because ∆H° is negative and less than 40 kJ/mol.

3.2.5 Regeneration of Amorphous Si/Cu Sample and Comparison with Other Adsorbents in the Literature

The loaded amorphous Si/Cu sample was regenerated and reused up to four cycles as described in the experimental part without changing their removing efficiency. The adsorption capacity of amorphous Si/Cu sample was compared with other adsorbents such as zeolite, raw kaolin, kaolin modified with graphene oxide, magnetic multi-wall carbon nanotube, silicon dioxide, coir pith carbon, carbon nanotubes, and amorphous metal silicates as shown in Table 2 [21, 33,34,35,36,37,38]. The results proved the effectiveness of the obtained adsorbent in the removal of methylene blue dye where the adsorption capacity of it was 102.05 mg/g.

4 Conclusions

Amorphous Si/Cu sample was obtained utilizing the gelation technique for the efficient removal of methylene blue dye. The maximum adsorption capacity of the obtained adsorbent was 102.05 mg/g. Also, the Freundlich isotherm and pseudo-first-order kinetic model controlled the adsorption process. Besides, the negative ∆G° values affirmed the spontaneous properties of the adsorption. Moreover, the adsorption was exothermic and physical. The non-crystalline properties of the obtained Si/Cu sample was confirmed through the presence of XRD broadband in the range 2θ = 16°–46°. The peaks at 0.93, 8.04, and 8.91 keV confirmed the presence of Cu Lα, Cu Kα, and Cu Kβ, respectively. Also, the peaks at 0.53, 1.04, and 1.74 keV confirmed the presence of O, Na, and Si, respectively. The % Cu, % Si, % Na, and % O were 54.22, 23.60, 4.98, and 17.20%, respectively.

References

M.E. Mahmoud, G.M. Nabil, M.A. Khalifa, N.M. El-mallah, H.M. Hassouba, Effective removal of crystal violet and methylene blue dyes from water by surface functionalized zirconium silicate nanocomposite. J. Environ. Chem. Eng. 7, 103009 (2019)

S. Khe, M. Ching, N. Ling, Effect of ultrasound pre-treatment on adsorbent in dye adsorption compared with ultrasound simultaneous adsorption. Ultrason. Sonochem. 48, 64–70 (2018)

M. Rafatullah, O. Sulaiman, R. Hashim, A. Ahmad, Adsorption of methylene blue on low-cost adsorbents: a review. J. Hazard. Mater. 177, 70–80 (2010)

S. Bentahar, A. Dbik, M. El Khomri, N. El Messaoudi, Adsorption of methylene blue, crystal violet and congo red from binary and ternary systems with natural clay: kinetic, isotherm, and thermodynamic. J. Environ. Chem. Eng. 5, 5921–5932 (2017)

S. Chatterjee, S. Lim, S.H. Woo, Removal of Reactive Black 5 by zero-valent iron modified with various surfactants. Chem. Eng. J. 160, 27–32 (2010)

Y. Miyah, A. Lahrichi, M. Idrissi, A. Khalil, F. Zerrouq, Adsorption of methylene blue dye from aqueous solutions onto walnut shells powder: equilibrium and kinetic studies. Surf. Interfaces 11, 74–81 (2018)

N. Nikooe, E. Saljoughi, Preparation and characterization of novel PVDF nanofiltration membranes with hydrophilic property for filtration of dye aqueous solution. Appl. Surf. Sci. 413, 41–49 (2017)

M.E. Osugi, K. Rajeshwar, E.R.A. Ferraz, D.P. De Oliveira, Â.R. Araújo, M. Valnice, B. Zanoni, Comparison of oxidation efficiency of disperse dyes by chemical and photoelectrocatalytic chlorination and removal of mutagenic activity. Electrochim. Acta 54, 2086–2093 (2009)

T. Kim, C. Park, J. Yang, S. Kim, Comparison of disperse and reactive dye removals by chemical coagulation and Fenton oxidation. J. Hazard. Mater. 112, 95–103 (2004)

X. Li, S. Tang, D. Yuan, J. Tang, C. Zhang, N. Li, Y. Rao, Improved degradation of anthraquinone dye by electrochemical activation of PDS. Ecotoxicol. Environ. Saf. 177, 77–85 (2019)

L. Gui, J. Peng, P. Li, R. Peng, P. Yu, Y. Luo, Electrochemical degradation of dye on TiO2 nanotube array constructed anode. Chemosphere 235, 1189–1196 (2019)

S. Sharma, N. Khare, Hierarchical Bi2S3 nanoflowers: a novel photocatalyst for enhanced photocatalytic degradation of binary mixture of Rhodamine B and Methylene blue dyes and degradation of mixture of p-nitrophenol and p-chlorophenol. Adv. Powder Technol. 29, 3336–3347 (2018)

X. Xie, N. Liu, F. Yang, Q. Zhang, X. Zheng, Y. Wang, Comparative study of antiestrogenic activity of two dyes after Fenton oxidation and biological degradation. Ecotoxicol. Environ. Saf. 164, 416–424 (2018)

J. Wu, L. Ma, Y. Chen, Y. Cheng, Y. Liu, X. Zha, Catalytic ozonation of organic pollutants from bio-treated dyeing and finishing wastewater using recycled waste iron shavings as a catalyst: removal and pathways. Water Res. 92, 140–148 (2016)

S. Maria, D.A. Guelli, U. De Souza, K. Angela, S. Bonilla, A. Augusto, U. De Souza, Removal of COD and color from hydrolyzed textile azo dye by combined ozonation and biological treatment. J. Hazard. Mater. 179, 35–42 (2010)

V. Katheresan, J. Kansedo, S.Y. Lau, Efficiency of various recent wastewater dye removal methods: a review. J. Environ. Chem. Eng. 6, 4676–4697 (2018)

H. Mittal, S.M. Alhassan, S. Sinha, Efficient organic dye removal from wastewater by magnetic carbonaceous adsorbent prepared from corn starch. J. Environ. Chem. Eng. 6, 7119–7131 (2018)

G. Patra, R. Barnwal, S.K. Behera, B.C. Meikap, Removal of dyes from aqueous solution by sorption with fly ash using a hydrocyclone. J. Environ. Chem. Eng. 6, 5204–5211 (2018)

E.A. Moawed, A.E. Wahba, R.A. Gabr, Synthesis and application of LGB/St/Al2O3 biocomposite for sensitive detection and efficient removal of brilliant green dye from wastewater. J. Environ. Chem. Eng. 6, 7225–7232 (2018)

L. Aljerf, High-efficiency extraction of bromocresol purple dye and heavy metals as chromium from industrial effluent by adsorption onto a modified surface of zeolite: kinetics and equilibrium study. J. Environ. Manag. 225, 120–132 (2018)

E.A. Abdelrahman, R.M. Hegazey, R.E. El-azabawy, Efficient removal of methylene blue dye from aqueous media using Fe/Si, Cr/Si, Ni/Si, and Zn/Si amorphous novel adsorbents, J. Mater. Res. Technol. https://doi.org/10.1016/j.jmrt.2019.08.051

C. Arora, S. Soni, S. Sahu, J. Mittal, P. Kumar, P.K. Bajpai, Iron based metal organic framework for efficient removal of methylene blue dye from industrial waste. J. Mol. Liq. 284, 343–352 (2019)

S. Lapwanit, T. Sooksimuang, T. Trakulsujaritchok, Adsorptive removal of cationic methylene blue dye by kappa-carrageenan/poly(glycidyl methacrylate) hydrogel beads: preparation and characterization. J. Environ. Chem. Eng. 6, 6221–6230 (2018)

W.A. Khanday, M. Asif, B.H. Hameed, Cross-linked beads of activated oil palm ash zeolite/chitosan composite as a bio-adsorbent for the removal of methylene blue and acid blue 29 dyes. Int. J. Biol. Macromol. 95, 895–902 (2017)

M. Wang, R. Xie, Y. Chen, X. Pu, W. Jiang, L. Yao, A novel mesoporous zeolite-activated carbon composite as an effective adsorbent for removal of ammonia-nitrogen and methylene blue from aqueous solution. Bioresour. Technol. 268, 726–732 (2018)

D.M. El-mekkawi, F.A. Ibrahim, M.M. Selim, Removal of methylene blue from water using zeolites prepared from Egyptian kaolins collected from different sources. Biochem. Pharmacol. 4, 1417–1422 (2016)

N.H. Othman, N.H. Alias, M.Z. Shahruddin, N. Fitrah, A. Bakar, N. Raikhan, N. Him, W. Jye, Adsorption kinetics of methylene blue dyes onto magnetic graphene oxide. J. Environ. Chem. Eng. 6, 2803–2811 (2018)

H.M. Aly, M.E. Moustafa, E.A. Abdelrahman, Influence of aluminum source on the synthesis of nanosized ZSM-5 zeolite. Der Chem. Sin. 4, 68–72 (2013)

E.A. Abdelrahman, R.M. Hegazey, Exploitation of Egyptian insecticide cans in the fabrication of Si/Fe nanostructures and their chitosan polymer composites for the removal of Ni(II), Cu(II), and Zn(II) ions from aqueous solutions. Composites B 166, 382–400 (2019)

E.A. Abdelrahman, R.M. Hegazey, Utilization of waste aluminum cans in the fabrication of hydroxysodalite nanoparticles and their chitosan biopolymer composites for the removal of Ni(II) and Pb(II) ions from aqueous solutions: kinetic, equilibrium, and reusability studies. Microchem. J. 145, 18–25 (2019)

E.A. Abdelrahman, Synthesis of zeolite nanostructures from waste aluminum cans for efficient removal of malachite green dye from aqueous media. J. Mol. Liq. 253, 72–82 (2018)

E.A. Abdelrahman, E.T. Abdel-salam, S.M. El Rayes, N.S. Mohamed, Facile synthesis of graft copolymers of maltodextrin and chitosan with 2-acrylamido-2-methyl-1-propanesulfonic acid for efficient removal of Ni(II), Fe(III), and Cd(II) ions from aqueous media, J. Polym. Res. (2019) https://doi.org/10.1007/s10965-019-1920-4

K. Rida, S. Bouraoui, S. Hadnine, Adsorption of methylene blue from aqueous solution by kaolin and zeolite. Appl. Clay Sci. 83–84, 99–105 (2013)

D. Ghosh, K.G. Bhattacharyya, Adsorption of methylene blue on kaolinite. Appl. Clay Sci. 20, 295–300 (2002)

K. He, G. Chen, G. Zeng, A. Chen, Z. Huang, J. Shi, M. Peng, T. Huang, L. Hu, Journal of the Taiwan Institute of Chemical Engineers enhanced removal performance for methylene blue by kaolin with graphene oxide modification. J. Taiwan Inst. Chem. Eng. 89, 77–85 (2018)

J. Gong, B. Wang, G. Zeng, C. Yang, C. Niu, Q. Niu, Removal of cationic dyes from aqueous solution using magnetic multi-wall carbon nanotube nanocomposite as adsorbent. J. Hazard. Mater. 164, 1517–1522 (2009)

E. Nazarzadeh, A. Motahari, M. Sillanpää, Nanoadsorbents based on conducting polymer nanocomposites with main focus on polyaniline and its derivatives for removal of heavy metal ions/dyes: a review. Environ. Res. 162, 173–195 (2018)

D. Kavitha, C. Namasivayam, Experimental and kinetic studies on methylene blue adsorption by coir pith carbon. Bioresour. Technol. 98, 14–21 (2007)

Acknowledgements

The author would like to thank the Deanship of Scientific Research at Umm Al-Qura University for the continuous support. This work was supported financially by the Deanship of Scientific Research at Umm Al-Qura University (Grant Code 18-SCI-1-02-0005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hameed, A.M. Synthesis of Si/Cu Amorphous Adsorbent for Efficient Removal of Methylene Blue Dye from Aqueous Media. J Inorg Organomet Polym 30, 2881–2889 (2020). https://doi.org/10.1007/s10904-019-01436-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-019-01436-1