Abstract

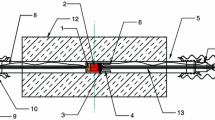

The effect of nickel on surface energy of the solid/gas interface of silver was studied. The measurements were taken using foils according to the previously developed in situ method in an atmosphere of Ar + 10% H2 at high temperatures. This method simultaneously allows one to determine the surface energy and diffusion creep rate. The solubility of nickel in silver is very low, so the measurements were taken for the alloys in the two-phase region with 0.45 at.% Ni and 1.5 at.% Ni, as well as for pure nickel. Nickel is shown to significantly increase the surface energy of silver and slow down the diffusion creep rate.

Similar content being viewed by others

References

C. Srivastava, S. Chithra, K.D. Malviya, S.K. Sinha, and K. Chattopadhyay, Size Dependent Microstructure for Ag-Ni Nanoparticles. Acta Mat. 59(16), 6501–6509 (2011)

R. Meyer, S. Prakash, and P. Entel, Capillary Pressure and Phonons in Ag, Au, Cu and Ni Nanoparticles. Phase Trans. 75(1–2), 51–58 (2002)

J. Zhong, L.H. Zhang, Z.H. Jin, M.L. Sui, and K. Lu, Superheating of Ag Nanoparticles Embedded in Ni Matrix. Acta Mat. 49, 2897–2904 (2001)

Z. Zhao, A. Fisher, and D. Cheng, Phase Diagram and Segregation of Ag-Co Nanoalloys: Insights from Theory and Simulation. Nanotechnology 27, 115702-1–115702-11 (2016)

G. Kaptay, Nano-Calphad: Extension of the Calphad Method to Systems with Nano-phases and Complexions. J. Mater. Sci. 47(24), 8320–8335 (2012)

J. Bian, G. Wang, and X. Feng, Atomistic Calculations of Surface Energy of Spherical Copper Surfaces. Acta Mech. Solids Sin. 25, 557–561 (2012)

D. Gozzi, M. Tomellini, L. Lazzarini, and A. Latini, High-Temperature Determination of Surface Free Energy of Copper Nanoparticles. J. Phys. Chem. C. 114, 12117–12124 (2010)

L. Schimka, J. Harl, A. Stroppa, A. Grüneis, M. Marsman, F. Mittendorfer et al., Accurate Surface and Adsorption Energies from Many-Body Perturbation Theory. Nat. Mater. 9, 741–744 (2010)

S. Zhevnenko and D. Vaganov, Isotherms of Grain Boundary Tension and Grain Boundary Adsorption In Cu-Sn System. Defect Diffus. Forum 258–260, 427–432 (2006)

D. Vaganov and S. Zhevnenko, Determination of Copper Self-diffusion Coefficients on the Base of High-Temperature Creep Data. Defect Diffus. Forum 249, 115–118 (2006)

S.N. Zhevnenko and E.I. Gershman, Method of In Situ Measuring Surface Tension of a Solid–Gas Interface. Phys. Met. Metallogr. 110, 102–107 (2010)

S.N. Zhevnenko, Isotherms of Surface Tension in Copper-Based Systems. Phys. Met. Metallogr. 106, 276–283 (2008)

S. Zhevnenko and A.K. Khayrullin, Interfacial Free Energy and Viscosity of Cu(Ag) Solid Solutions. J. Phys. Chem. C 120, 14082–14087 (2016)

S. Zhevnenko, Surface Free Energy of Copper-Based Solid Solutions. J. Phys. Chem. C 119, 2566–2571 (2015)

X.J. Liu, F. Gao, C.P. Wang, and K. Ishida, Thermodynamic Assessments of the Ag-Ni Binary and Ag-Cu-Ni Ternary Systems. J. Electron. Mater. 37(2), 210–217 (2008)

C. Herring, Diffusional Viscosity of a Polycrystalline Solid. J. Appl. Phys. 21, 437–445 (1950)

R.L. Coble, A Model for Boundary Diffusion Controlled Creep in Polycrystalline Materials. J. Appl. Phys. 34, 1679–1682 (1963)

E. Arzt, M.F. Ashby, and R.A. Verrall, Interface Controlled Diffusional Creep. Acta Mat. 31(13), 1977–1989 (1983)

S. Zhevnenko, Interfacial Free Energy of Cu-Co Solid Solutions. Metall. Mater. Trans. A 44(6), 2533–2538 (2013)

H. Udin, Surface Tension of Solid Copper. Doctor thesis (Massachusetts Institute of Technology, 1940).

S.N. Zhevnenko, Direct Measurements of Surface Free Energy of Solid Solutions: Phase Transitions and Complexions. Top Catal. 61(15–17), 1707–1715 (2018)

A.V. Ruban, H.L. Skriver, and J.K. Norskov, Surface Segregation Energies in Transition-Metal Alloys. Phys. Rev. B 59(24), 15990–16000 (1999)

B. Burton, Interface Reaction Controlled Diffusional Creep: A Consideration of Grain Boundary Dislocation Climb Sources. Mater. Sci. Eng. 10, 9–14 (1972)

B. Burton, Diffusional Creep of Polycrystalline Materials (Trans. Tech. Publications, Zurich, 1977)

M. Magri, G. Lemoine, L. Adam, and J. Segurado, A Coupled Model of Diffusional Creep of Polycrystalline Solids Based on Climb of Dislocations at Grain Boundaries. J. Mech. Phys. Solids, 135, 103786–20 (2020)

B.Q. Han, and D.C. Dunand, Creep of Magnesium Strengthened with High Volume Fractions of Yttria Dispersoids. Mater. Sci. Eng. A 300, 235–244 (2001)

B. Burton, On the Mechanism of the Inhibition of Diffusional Creep by Second Phase Particles. Mater. Sci. Eng. 11, 337–343 (1973)

E.A. Clark, R. Yeske, and H.K. Birnbaum, The Effect of Hydrogen on the Surface Energy of Nickel. Metall. Mater. Trans. A 11A, 1903–1908 (1980)

T.A. Roth, The Surface and Grain Boundary Energies of Iron, Cobalt and Nickel. Mater. Sci. Eng. 18, 183–192 (1975)

R.M. Digilov, S.N. Zadumkin, V.K. Kumykov, and KhB Khokonov, Measurement of Surface Tension of Refractory Metals in Solid State. Phys. Met. Metallogr. 41(5), 979–982 (1976)

L.E. Murr, O.T. Inal, and G.I. Wong, Electron Microscopy and the Structure of Metals, G. Thomas, ed. (University of California Press, Berkeley, 1972), p. 471.

T.M. Williams, and P. Barrand, The Measurement of the Ratio of Grain-Boundary Energy to Surface Energy as a Function of Composition, for the Copper–Nickel System. J. Inst. Met. 93, 447–452 (1965)

E.R. Hayward and A.P. Greenough, The Surface Energy of Solid Nickel. J. Inst. Met. 88, 217–221 (1959)

P.S. Maiya and J.M. Blakely, Surface Self-diffusion and Surface Energy of Nickel. J. Appl. Phys. 38, 698–704 (1967)

F.H. Buttner, E.R. Funk, and H. Udin, Adsorption of Oxygen on Silver. J. Phys. Chem. 56, 657–660 (1952)

Acknowledgments

The reported study was supported by the Russian Foundation for Basic Research in the study of measuring surface energy (Project No. 18-02-00752) and the Russian Science Foundation in the study of diffusion creep and surface morphology (Project No. 19-72-10160).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhevnenko, S.N., Dmitrieva, I.O. & Antonova, V.E. Effect of Ni on Surface Energy and Diffusion Creep of Solid Ag. J. of Materi Eng and Perform 29, 4833–4839 (2020). https://doi.org/10.1007/s11665-019-04529-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04529-7