Abstract

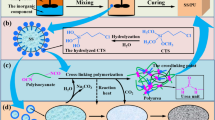

In the current work, organosepiolite (O-Sep) was prepared via modification of sepiolite (Sep) with silane coupler γ-methacryloxypropyltrimethoxysilane (CG-570) and polypropylene (PP)/ polyamide 6 (PA6) blends were introduced to investigate the effect on thermomechanical properties of polymer-based nanocomposites. Scanning electron microscopy (SEM), transmission electron microscopy (TEM), thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), and rotational rheometer were employed to characterize the morphology and thermomechanical properties of materials. The results show that O-Sep improved the dispersion of PA6 in the PP matrix and enhanced both the mechanical behavior and thermal properties of the PP/PA6/O-Sep nanocomposites.

Similar content being viewed by others

References

Wang L, Okada K, Sodenaga M, Hikima Y, Ohshima M, Sekiguchi T, Yano H (2018) Effect of surface modification on the dispersion, rheological behavior, crystallization kinetics, and foaming ability of polypropylene/cellulose nanofiber nanocomposites. Compos Sci Technol 168:412–419

Hammani S, Moulai-Mostefa N, Benyahia L, Tassin J-F (2012) Effects of composition and extrusion parameters on the morphological development and rheological properties of PP/PC blends. Co-continuity investigation. J Polym Res 19(8):9940

Pustak A, Denac M, Škapin AS, Švab I, Musil V, Šmit I (2016) Mechanical and rheological properties of silica-reinforced polypropylene/m-EPR blends. J Polym Res 23(8):163

Ji H, Zhou X, Chen X, Zhao H, Wang Y, Zhu H, Shan X, Sha J, Ma Y, Xie L (2019) Effects of solid-state stretching on microstructure evolution and physical properties of isotactic polypropylene sheets. Polymers 11(4):618

Tian M, Han J, Zou H, Tian H, Wu H, She Q, Chen W, Zhang L (2012) Dramatic influence of compatibility on crystallization behavior and morphology of polypropylene in NBR/PP thermoplastic vulcanizates. J Polym Res 19(1):9745

Lee HG, Sung Y-T, Lee YK, Kim WN (2009) Effects of PP-g-MAH on the mechanical, morphological and rheological properties of polypropylene and poly(acrylonitrile-butadiene-styrene) blends. Macromol Res 17(6):417–423

Bonda S, Mohanty S, Nayak SK (2014) Influence of compatibilizer on mechanical, morphological and rheological properties of PP/ABS blends. Iran Polym J 23(6):415–425

Sun H, Zhao Z, Yang Q, Yang L, Wu P (2017) The morphological evolution and β-crystal distribution of isotactic polypropylene with the assistance of a long chain branched structure at micro-injection molding condition. J Polym Res 24(5):75

Laguna-Gutierrez E, Lopez-Gil A, Lopez-Gil C, Hooghten RV, Moldenaers P, Rodriguez-Perez MA (2016) Extensional rheology, cellular structure, mechanical behavior relationships in HMS PP/montmorillonite foams with similar densities. J Polym Res 23(12):251

Bilotti E, Fischer HR, Peijs T (2008) Polymer nanocomposites based on needle-like sepiolite clays: effect of functionalized polymers on the dispersion of nanofiller, crystallinity, and mechanical properties. J Appl Polym Sci 107(2):1116–1123

Bigdeli A, Nazockdast H, Rashidi A, Yazdanshenas ME (2012) Role of nanoclay in determining microfibrillar morphology development in PP/PBT blend nanocomposite fibers. J Polym Res 19(11):9990

Hapuarachchi TD, Peijs T, Bilotti E (2013) Thermal degradation and flammability behavior of polypropylene/clay/carbon nanotube composite systems. Polym Adv Technol 24(3):331–338

He M, Cao WC, Wang LJ, Wilkie CA (2013) Synergistic effects of organo-sepiolite and zinc borate on the fire retardancy of polypropylene. Polym Adv Technol 24(12):1081–1088

Kodgire P, Kalgaonkar R, Hambir S, Bulakh N (2001) PP/clay nanocomposites: effect of clay treatment on morphology and dynamic mechanical properties. J Appl Polym Sci 81:1786–1792

Liu J, Zhu X (2019) Isotactic polypropylene toughened with poly(acrylonitrile-butadiene-styrene): Compatibilizing role of nano-ZnO. Polym-Plast Technol mater https://doi.org/10.1080/e25740881.2019.1599943

Mousavian S, Ebadi-Dehaghani H, Ashouri D, Sadeghipour H, Jabbari F (2012) Effect of polymer matrix on the magnetic properties of polymer bonded magnets filled Fe3O4 nanoparticles. J Polym Res 19(11):9991

Mao H, He B, Guo W, Hua L, Yang Q (2018) Effects of nano-CaCO3 content on the crystallization, mechanical properties, and cell structure of PP nanocomposites in microcellular injection molding. Polymers 10(10):1160

As’habi L, Jafari SH, Khonakdar HA, Baghaei B (2011) Morphological, rheological and thermal studies in melt processed compatibilized PA6/ABS/clay nanocomposites. J Polym Res 18(2):197–205

Ou B, Chen M, Zhou H (2016) Non-isothermal crystallization and melting behaviors of PP/PA6/TiO2 nanocomposites. Polym-Plast Technol 56(5):506–525

EGRD A, Backes EH, Marini J, Pessan LA, Montagna LS, Passador FR (2019) Effect of LLDPE-g-MA on the rheological, thermal, mechanical properties and morphological characteristic of PA6/LLDPE blends. J Polym Res 26(6):134

Babaei A, Arefazar A (2015) Structural, rheological, and mechanical properties of PA6/SAN/SEBS ternary blend/organoclay nanocomposites. J Appl Polym Sci 132(20):41969

Beuguel Q, Ville J, Crepin-Leblond J, Mederic P, Aubry T (2017) Influence of clay mineral structure and polyamide polarity on the structural and morphological properties of clay polypropylene/polyamide nanocomposites. Appl Clay Sci 135:253–259

Caro AS, Parpaite T, Otazaghine B, Taguet A, Lopez-Cuesta JM (2017) Viscoelastic properties of polystyrene/polyamide-6 blend compatibilized with silica/polystyrene Janus hybrid nanoparticles. J Rheol 61(2):305–310

Cheng Z-L, Ma L, Liu Z (2018) A study on synergistic reinforcing effect of halloysite nanotubes/diatomite mixture-filled polymer (PP and PA6) composites. Plast Rubber Compos 47(6):249–257

Shao H, Wu B, Yang J, Zhang K, Qin S (2015) Effect of LiCl on the miscibility and crystallization behavior of a hydrophilic PP/PP-g-MAH/PA6 blend. J Polym Res 22(5):70

Fu D, Chen F, Peng X, Kuang T (2018) Polyamide 6 modified polypropylene with remarkably enhanced mechanical performance, thermal properties, and foaming ability via pressure-induced-flow processing approach. Adv Polym Technol 37(8):2721–2729

Gooneie A, Nazockdast H, Shahsavan F (2015) Effect of selective localization of carbon nanotubes in PA6 dispersed phase of PP/PA6 blends on the morphology evolution with time, part 1: droplet deformation under simple shear flows. Polym Eng Sci 55(7):1504–1519

Hajiraissi R, Jahani Y, Hallmann T (2018) Investigation of rheology and morphology to follow physical fibrillar network evolution through fiber spinning of PP/PA6 blend fiber. Polym Eng Sci 58(8):1251–1260

Li H, Sui X, Xie X-M (2017) High-strength and super-tough PA6/PS/PP/SEBS quaternary blends compatibilized by using a highly effective multi-phase compatibilizer: toward efficient recycling of waste plastics. Polymer 123:240–246

Zhang N, Liu J, Chen SN, Huang LH, Feng QL, Zheng SC (2016) Expression profiles of glutathione S-transferase superfamily in Spodopteralituratolerated to sublethal doses of chlorpyrifos. Insect Sci 23(5):675–687

Wang J, Ponting M, Zhang C, Olah A, Baer E (2017) Fuel filtration properties and mechanism of a novel fibrous filter produced by a melt-process. J Membrane Sci 526:229–241

Shao H, Wu B, Yang J, Zhang K, Qin S (2015) Effect of LiCl on the miscibility and crystallization behavior of a hydrophilic PP/PP-g-MAH/PA6 blend. J Polym Res 22(5):70

Palacios JK, Sangroniz A, Eguiazabal JI, Etxeberria A, Müller AJ (2016) Tailoring the properties of PP/PA6 nanostructured blends by the addition of nanosilica and compatibilizer agents. Eur Polym J 85:532–552

Manchanda B, Vimal KK, Kapur GS, Kant S, Choudhary V (2016) Effect of sepiolite on nonisothermal crystallization kinetics of polypropylene. J Mater Sci 51(21):9535–9550

Manchanda B, Kakkarakkal Kottiyath V, Kapur GS, Kant S, Choudhary V (2017) Morphological studies and thermo-mechanical behavior of polypropylene/sepiolite nanocomposites. Polym Compos 38:E285–E294

Mohd Zaini NA, Ismail H, Rusli A (2017) Short review on sepiolite-filled polymer nanocomposites. Polym-Plast Technol Eng 56(15):1665–1679

Laoutid F, Persenaire O, Bonnaud L, Dubois P (2013) Flame retardant polypropylene through the joint action of sepiolite and polyamide 6. Polym Degrad Stabil 98(10):1972–1980

Singh VP, Kapur GS, Shashikant S, Choudhary V (2016) High-density polyethylene/needle-like sepiolite clay nanocomposites: effect of functionalized polymers on the dispersion of nanofiller, melt extensional and mechanical properties. RSC Adv 6:59762–59774

Singh VP, Vimal KK, Shashikant S, Kapur GS, Choudhary V (2017) Polyethylene/sepiolite clay nanocomposites: effect of clay content, compatibilizer polarity, and molar mass on viscoelastic and dynamic mechanical properties. J Appl Polym Sci 134(33):45197

Mejía A, García N, Guzmán J, Tiemblo P (2014) Surface modification of sepiolite nanofibers with PEG based compounds to prepare polymer electrolytes. Appl Clay Sci 95:265–274

García N, Guzmán J, Benito E, Esteban-Cubillo A, Aguilar E, Santaren J, Tiemblo P (2011) Surface modification of sepiolite in aqueous gels by using methoxysilanes and its impact on the nanofiber dispersion ability. Langmuir 27:3952–3959

Chang Y, Liu Z, Fu Z, Wang C, Dai Y, Peng R, Hu X (2013) Preparation and characterization of one-dimensional core-shell sepiolite/polypyrrole nanocomposites and effect of organic modification on the electrochemical properties. Ind Eng Chem Res 53(1):38–47

García-López D, Fernández JF, Merino JC, Santarén J, Pastor JM (2010) Effect of organic modification of sepiolite for PA 6 polymer/organoclay nanocomposites. Compos Sci Technol 70(10):1429–1436

Mohd Zaini NA, Ismail H, Rusli A (2018) Sepiolite hybridized commercial fillers, and their effects on curing process, mechanical properties, thermal stability, and flammability of ethylene propylene diene monomer rubber composites. Iran Polym J 27(9):663–675

Liao J, Brosse N, Pizzi A, Hoppe S, Xi X, Zhou X (2019) Polypropylene blend with polyphenols through dynamic vulcanization: mechanical, rheological, crystalline, thermal, and UV protective property. Polymers 11(7):1108

Acknowledgments

This work was financially supported by Guizhou Provincial Department of Education Natural Foundation (2015400), talent introduction project of Guiyang University by Guiyang City Financial Support Guiyang University (2019039510822), special funding of Guiyang Science and Technology Bureau and Guiyang University (GYU-KYZ < 2019-2020 > PT23-07), and Guizhou Youth Science and Technology Talents Project (KY2019085).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, K., Xie, J., Li, T. et al. Surface modification of sepiolite: effects on thermomechanical properties of PP/PA6 blends. J Polym Res 27, 25 (2020). https://doi.org/10.1007/s10965-019-2000-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-2000-5