Abstract

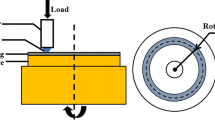

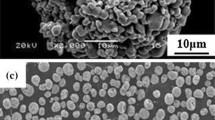

In this work, the wear performance of nano- and ordinary MoSi2 plasma-sprayed coating on Ni substrate are compared. MoSi2 nanopowder is prepared by ball milling followed by heat treatment processes. Atmospheric plasma spraying with argon atmosphere protection has been used to deposit the powders onto the nickel substrate. Ni substrate, MoSi2 coating, and nano-MoSi2 coating were subjected to reciprocating wear test. Wear tests were done on a pin on plate machine by sliding MoSi2 coating and substrates without coating against 52100 steel as the pin, at a temperature of 27 °C in dry condition. A friction coefficient of 0.18 ± 0.1 is obtained for nanostructured MoSi2 coating, whereas a friction coefficient of 0.2 ± 0.1 is obtained for conventional MoSi2 coating under normal load of 20 N. Wear performance of nanostructured MoSi2 coating was better as compared to the conventional MoSi2 coating. The three observed dominant types of wear mechanisms were adhesive, oxidation and abrasive. Morphologies and phases of coating, wear tracks, wear debris and counterpart steel pins were evaluated by SEM with EDS and X-ray diffraction. The microhardness and adhesion strength of nanostructured MoSi2 coating are determined by 1000 HV and 27 MPa, respectively.

Graphic Abstract

Similar content being viewed by others

References

A. Vasudevan, J. Petrovic, A comparative overview of molybdenum disilicide composites. Mater. Sci. Eng. A 155(1–2), 1–17 (1992)

J.-H. Yan, X. Jian-jian, U.D. Rafi, Y. Wang, L.-F. Liu, Preparation of agglomerated powders for air plasma spraying MoSi2 coating. Ceram. Int. 41((9, Part A)), 10547–10556 (2015)

M. Salek, S.R. Bakhshi, M. Erfanmanesh, Atmospheric plasma spraying of nanocrystalline SiC particle reinforced MoSi2 prepared by mechanically activated annealing process. J. Aust. Ceram. Soc. (2019)

R. Mitra, Mechanical behaviour and oxidation resistance of structural silicides. Int. Mater. Rev. 51(1), 13–64 (2006)

G.-D. Sun, G.-H. Zhang, Study on the preparation of molybdenum silicides by the silicothermic reduction of MoS2. J. Alloy. Compd. 728, 295–306 (2017)

Y. Niu, C. Zhai, G. Wang, L. Huang, X. Zheng, C. Ding, Microstructure evolution of plasma-sprayed MoSi2 coating at RT-1200 °C in air. J. Therm. Spray Technol. 27(6), 938–948 (2018)

Y. Zhang, S. Hussain, K. Cui, T. Fu, J. Wang, M.S. Javed et al., Microstructure and mechanical properties of MoSi2 coating deposited on Mo substrate by hot dipping processes. J. Nanoelectron. Optoelectron. 14(12), 1680–1685 (2019)

X. Fei, Y. Niu, H. Ji, L. Huang, X. Zheng, A comparative study of MoSi2 coatings manufactured by atmospheric and vacuum plasma spray processes. Ceram. Int. 37(3), 813–817 (2011)

G. Reisel, B. Wielage, S. Steinhäuser, I. Morgenthal, R. Scholl, High temperature oxidation behavior of HVOF-sprayed unreinforced and reinforced molybdenum disilicide powders. Surf. Coat. Technol. 146, 19–26 (2001)

J.-K. Yoon, J.-M. Doh, J.-Y. Byun, G.-H. Kim, J.-K. Lee, K.-T. Hong, Formation of MoSi2–SiC composite coatings by chemical vapor deposition of Si on the surface of Mo2C layer formed by carburizing of Mo substrate. Surf. Coat. Technol. 173(1), 39–46 (2003)

S.V. Joshi, M.P. Srivastava, M. Chatterjee, J. Ray, A. Chatterjee, D. Ganguli, Plasma spraying of an indigenous yttria stabilized zirconia powder prepared by the sol–gel technique. Bull. Mater. Sci. 16(1), 19–28 (1993)

K.A. Durga Prasad, K.C. Lahiry, D.M. Reddy, S.C. Mohan, S.R. Kumar, N. Ramadass et al., Effect of oxide additions on the properties of plasma-sprayed Y–Ba–Cu–O coatings. Bull. Mater. Sci. 14(2), 457–459 (1991)

D.S. Patil, K.P. Sreekumar, N. Venkataramani, R.K. Iyer, R. Prasad, R.S. Koppikar et al., Plasma sprayed hydroxy apatite coatings. Bull. Mater. Sci. 19(1), 115 (1996)

M. Erfanmanesh, S.R. Bakhshi, Oxidation behavior of nanostructured and conventional MoSi2 plasma-sprayed coatings. Ceram. Int. 44(13), 15839–15844 (2018)

G. Singh, H. Singh, B.S. Sidhu, In vitro corrosion investigations of plasma-sprayed hydroxyapatite and hydroxyapatite-calcium phosphate coatings on 316L SS. Bull. Mater. Sci. 37(6), 1519–1528 (2014)

X.-P. Hu, W.-C. Tan, S.-W. Tang, H.-A. Zhang, Z.-C. Huang, High-temperature wear behaviors of MoSi2 under different loads. Trans. Nonferrous Metals Soc. China 17(s1A), s60–s63 (2007)

H. Zhang, S. Tang, J. Yan, C. Zhang, Fabrication and wear characteristics of MoSi2 matrix composites reinforced by La2O3 and Mo5Si3. Int. J. Refract Metal Hard Mater. 26(2), 115–119 (2008)

H. Zhang, G. Siyong, X. Nengping, Effect of La2O3 on the wear behavior of MoSi2 at high temperature. J. Rare Earths 29(4), 370–373 (2011)

M. Erfanmanesh, S.R. Bakhshi, Synthesis and characterization of nanocrystalline MoSi2 by mechanical alloying and heat treating. J. Cluster Sci. 24(1), 133–143 (2013)

S.R. Bakhshi, M. Erfanmanesh, P.R. Taleghani, Synthesize and preparation of MoSi2 powder using in plasma spraying process. Adv Process. Mater. 5(4), 6 (2012)

B. Wielage, G. Reisel, A. Wank, G. Fritsche, in Oxidation behaviour of molybdenum disilicide coating at 1500 °C Proceeding of Thermal Spray 2004. Japan (Osaka): Advances in Technology and Application (ASM International, 2004), pp. 478–481

F. Xiaoai, N. Yaran, J. Hengi, H. Liping, Z. Xuebin, A comparative study of MoSi2 coatings manufactured by atmospheric and vacuum plasma spray processes. Ceram. Int. 3874, 1–5 (2010)

I.M. Hutchings, P. Shipway, in Tribology: Friction and Wear of Engineering Materials (1992)

M. Salehi, F.A. Zadeh, in Surface Metallurgical and Tribological, 1st edn. (Iranaian society of surface science and technology, 1995)

B. Wielage, S. Steinhäuser, T. Schnick, D. Nickelmann, Characterization of the wear behavior of thermal sprayed coatings. J. Therm. Spray Technol. 8(4), 553–558 (1999)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Erfanmanesh, M., Bakhshi, S.R., Pakmanesh, M.R. et al. Preparation and Improved Friction and Wear Performance of the Nano-MoSi2 Coating on Ni Substrate by Plasma Spraying. Met. Mater. Int. 27, 1531–1539 (2021). https://doi.org/10.1007/s12540-019-00580-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00580-0