Abstract

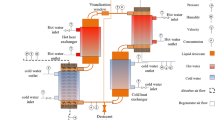

The natural convection energy recovery loop is analyzed experimentally in different airflow rates. The system was introduced previously as a prototype of the standalone air conditioning system and its transient and steady performance was verified. As a new generation of energy recovery tool between the building return and fresh air, the system is rated from the viewpoints of energy and exergy. Different forms of effectiveness and 2nd law efficiency are studied and their values extracted for inlet airflow rates of 2–6 m3/h. The results show that the prominent factor that controls the system behavior is the concentration ratio from which the solution free- motion originated. The maximum sensible, latent, and total effectiveness of the system are 0.23, 062, and 0.54 respectively and are for the airflow rate of 2m3/h. It is confirmed that the number of a transfer unit (NTU) and capacity ratio (Cr*) are not independent and are varied oppositely to each other. By increasing the airflow rate, the mass flow rate and heat capacity rate of desiccant solution increase more than that of air streams. For flow rates less than 3.5m3/h, external heat transfer is just enough to induce natural motion of desiccant and in this way the loop performance is similar to a forced convection energy transfer loop which exchanges heat and moisture only between the air streams.

Similar content being viewed by others

Abbreviations

- A:

-

Contact area (m2)

- Abs:

-

Absorber

- AC:

-

Air conditioning

- AHRI:

-

American society of heating and refrigerating institute

- ASTM:

-

American society of testing and materials

- C:

-

Concentration (kgsalt/kgsol)

- CC:

-

Cooling capacity (W)

- Cr* :

-

Specific heat ratio

- ECOP:

-

Electrical coefficient of performance

- H:

-

Specific enthalpy (kJ/kg)

- H:

-

Enthalpy (kJ)

- H/M:

-

Heat and mass

- HFM:

-

Hollow fiber membrane

- \( \dot{\mathrm{m}} \),m:

-

Mass flow rate (kg/s)

- MRR:

-

Moisture removal rate

- NTU:

-

Number of transfer unit

- PIV:

-

Particle imaging velocimetry

- R:

-

Mass flow rate ratio

- RAMEE:

-

Run around membrane energy exchanger

- Reg:

-

Regenerator

- SHR:

-

Sensible heat ratio

- TCOP:

-

Thermal coefficient of performance

- U:

-

Overall heat transfer coefficient (W/m2.K)

- Um :

-

Overall mass transfer coefficient (kg/m2.s)

- \( \dot{\mathrm{V}} \) :

-

Volume flow rate (m3/h)

- \( \dot{\mathrm{W}} \) :

-

Electrical power (W)

- ∆:

-

Difference

- ε:

-

Effectiveness

- η:

-

Efficiency

- ω:

-

Humidity ratio

- Ψ:

-

Exergy flow (kJ)

- 0:

-

Dead state

- A:

-

Air

- abs:

-

Absorber

- chiller:

-

Water chiller system

- comp:

-

Compressor

- cw:

-

Cold water

- db:

-

Dry bulb

- d, down:

-

Lower horizontal level of loop

- f:

-

Liquid water

- HMX:

-

Heat and mass exchanger

- hw:

-

Hot water

- in:

-

Inlet flow

- l:

-

Latent

- max:

-

Maximum value

- min:

-

Minimum value

- out:

-

Maximum value

- reg:

-

Regenerator

- s:

-

Sensible

- sol:

-

Desiccant solution

- tot:

-

Total

- u, up:

-

Upper horizontal level of loop

- v:

-

Water vapor

- w:

-

Liquid water

- wb:

-

Wet bulb

References

ASHRAE, “ventilation for acceptable indoor air quality,” Book ventilation for acceptable indoor air quality, Series ventilation for acceptable indoor air quality, ed., Editor ed.^eds., American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., 2007, pp.

ASHRAE, “thermal environmental conditions for human occupancy,” Book thermal environmental conditions for human occupancy, Series thermal environmental conditions for human occupancy, ed., Editor ed.^eds., American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc, 2004, pp.

Abdel-Salam AH, Ge G, Simonson CJ (2013) Performance analysis of a membrane liquid desiccant air-conditioning system. Energy and Buildings 62:559–569

Elsarrag E (2006) Dehumidification of air by chemical liquid desiccant in a packed column and its heat and mass transfer effectiveness. HVAC&R Research 12:3–16

Katejanekarn T, Kumar S (2008) Performance of a solar-regenerated liquid desiccant ventilation pre-conditioning system. Energy and Buildings 40:1252–1267

Ertas, A., Anderson, E.E., and Kiris, I., “Properties of a new liquid desiccant solution - Lithium chloride and calcium chloride mixture”, Solar Energy (Journal of Solar Energy Science and Engineering); (United States), Vol., pp. Medium: X; Size: Pages: 205–212, 1992

Enteria N, Yoshino H, Mochida A (2013) Review of the advances in open-cycle absorption air-conditioning systems. Renew Sust Energ Rev 28:265–289

Fan H, Besant RW, Simonson CJ, Shang W (2005) “Run-around heat recovery system using cross-flow flat-plate heat exchangers with aqueous ethylene glycol as the coupling fluid”, ASHRAE Transactions. Vol. 111

Afshin, M., “Selection of the liquid desiccant in a run-around membrane energy exchanger ” M.Sc. thesis, University of Saskatchewan, Saskatoon, 2010

Abdel-Salam AH, Ge G, Simonson CJ (2014) Thermo-economic performance of a solar membrane liquid desiccant air conditioning system. Sol Energy 102:56–73

Ramm VM (1968) Absorption of gases. Israel Program for Scientific Translation, Jerusalem

Liu XH, Jiang Y, Yi XQ (2009) Effect of regeneration mode on the performance of liquid desiccant packed bed regenerator. Renew Energy 34:209–216

Kessling W, Laevemann E, Kapfhammer C (1998) Energy storage for desiccant cooling systems component development. Sol Energy 64:209–221

Fumo N, Goswami DY (2002) Study of an aqueous lithium chloride desiccant system: air dehumidification and desiccant regeneration. Sol Energy 72:351–361

Ge G, Ghadiri Moghaddam D, Namvar R, Simonson CJ, Besant RW (2013) Analytical model based performance evaluation, sizing and coupling flow optimization of liquid desiccant run-around membrane energy exchanger systems. Energy and Buildings 62:248–257

Afshari A, Akbari M, Toghraie D, Yazdi ME (2018) Experimental investigation of rheological behavior of the hybrid nanofluid of MWCNT–alumina/water (80%)–ethylene-glycol (20%). J Therm Anal Calorim 132(2):1001–1015

Ahmadi G, Toghraie D, Akbari OA (2017) Solar parallel feed water heating repowering of a steam power plant: a case study in Iran. Renew Sust Energ Rev 77:474–485

M., S.-A., “Modeling the transient behavior of a run-around heat and moisture exchanger system,”.(M.Sc.thesis). Department of Mechanical Engineering, College of Engineering, University of Saskatchewan, Saskatoon, Saskatchewan, Canada: , 2008

Saman WY, Alizadeh S (2001) Modelling and performance analysis of a cross-flow type plate heat exchanger for dehumidification/cooling. Sol Energy 70:361–372

Namvar R, Ge G, Simonson CJ, Besant RW (2013) Transient heat and moisture transfer characteristics of a liquid-to-air membrane energy exchanger (LAMEE) model verification and extrapolation. Int J Heat Mass Transf 66:757–771

Moghaddam DG, G.G., Abdel-Salam AH, Besant RW, Simonson CJ. , “Effects of solution inlet temperature on the effectiveness and moisture removal rate of a liquid-to-airmembrane energy exchanger (LAMEE) during regenerator operating conditions,” Proc. In: Proceedings of the 24th CANCAM,, 2013

Moghaddam DG, LePoudre P, Ge G, Besant RW, Simonson CJ (2013) Small-scale single-panel liquid-to-air membrane energy exchanger (LAMEE) test facility development, commissioning and evaluating the steady-state performance. Energy and Buildings 66:424–436

Moghaddam DG, M.G., Ge G, Bolster J, BesantRW, SimonsonCJ., “Steady-state performance of a prototype (200CFM) liquid-to-air membrane energy exchanger (LAMEE) under summer and winter test conditions,” Proc. In: Proceedings of the ASME 2013 Summer Heat Transfer Conference, 2013

AHRI, A.A.S., “Standard for Rating Air-to-Air Exchangers for Energy Recovery Ventilation Equipment, Air-Conditioning & Refrigeration Institute,” Book Standard for Rating Air-to-Air Exchangers for Energy Recovery Ventilation Equipment, Air-Conditioning & Refrigeration Institute, Series Standard for Rating Air-to-Air Exchangers for Energy Recovery Ventilation Equipment, Air-Conditioning & Refrigeration Institute, ed., Editor ed.^eds., Arlington, VA, 2005, pp.

Abdel-Salam MRH, Besant RW, Simonson CJ (2016) Design and testing of a novel 3-fluid liquid-to-air membrane energy exchanger (3-fluid LAMEE). Int J Heat Mass Transf 92:312–329

Erb B (2009) M.S.a., C.J. Simonson, R.W. Besant, “experimental measurements of a run-around membrane energy exchanger (RAMEE) with comparison to numerical modeling”. ASHRAE Trans 111:901–910

Fan H, Simonson CJ, Besant RW, Shang W (2006) Performance of a run-around system for HVAC heat and moisture transfer applications using cross-flow plate exchangers coupled with aqueous Lithium bromide. HVAC&R Research 12:313–336

Hemingson HB, Simonson CJ, Besant RW (2011) Steady-state performance of a run-around membrane energy exchanger (RAMEE) for a range of outdoor air conditions. Int J Heat Mass Transf 54:1814–1824

Fazilati MA, Sedaghat A, Alemrajabi AA (2016) Natural induced flow due to concentration gradient in a liquid desiccant air dehumidifier. Appl Therm Eng 105:105–117

Fazilati MA, Sedaghat A, Alemrajabi A-A (2017) Transient performance and temperature field of a natural convection air dehumidifier loop. Heat Mass Transf 53:2287–2296

Fazilati MA, Alemrajabi AA, Sedaghat A (2017) Liquid desiccant air conditioning system with natural convection. Appl Therm Eng 115:305–314

Fazilati MA, Alemrajabi AA, Sedaghat A (2018) Natural convection liquid desiccant loop as an auxiliary air conditioning system: investigating the operational parameters. Heat Mass Transf 54:903–913

Chaudhari SK, Patil KR (2002) Thermodynamic properties of aqueous solutions of Lithium chloride. Phys Chem Liq 40:317–325

Moffat RJ (1988) Describing the uncertainties in experimental results. Exp Thermal Fluid Sci 1:3–17

Mohammad Ali Fazilati, A.A.A., “Natural convection liquid desiccant air conditioning system Performance Part I: system studies in different air flow rates”, submitted to be published

A., B., Advanced engineering thermodynamics, John Wiley & Sons, 2016

Acknowledgements

This research is partially supported by the National Key Research and Development Program of China (2016YFB0100903) and JITRI Suzhou Automotive Research Institute Project (CEC20190404).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, Y., Fazilati, M.A., Sedaghat, A. et al. Natural convection energy recovery loop analysis, part I: energy and exergy studies by varying inlet air flow rate. Heat Mass Transfer 56, 1685–1695 (2020). https://doi.org/10.1007/s00231-019-02766-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02766-z