Abstract

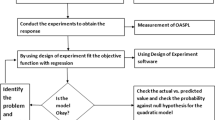

The enhancement of heat transfer from the impinging jets can be reason of tens of parameters. In earlier studies, researchers have done numerous experiments or numerical runs to show the effect of each parameter individually. However, in recent decade some new methodologies, such as Design of Experiment (DoE) and Analysis of Variance (ANOVA) have been used to achieve more comparative parameter analysis and to optimize the number of experiments (or numerical runs). In this study, DoE and ANOVA methods are applied to an experimental impinging jet study. The jet geometry and roughness of impingement plate are the main considered parameters of this study. Beside them, effects of jet-to-surface distance (H) and radial distance (r) on the target surface are analyzed. The data runs are performed for a constant jet Reynolds number 20,000. The Taguchi DoE method is applied to the study in order to design the experiments. Totally 18 experiments are run base on the orthogonal array of L18 (16) (33), and effects of each design parameter on heat transfer is found out by ANOVA. As a result, it is concluded that, the highest effect on Nusselt number is observed to be the radial distance (88%), while surface roughness has the effect in percentage of 8%. The contribution of jet geometry and jet-to-surface distance are much lower, as being 3% and 1%, respectively.

Similar content being viewed by others

Abbreviations

- A :

-

Surface area of the target plate, m2

- D h :

-

Hydraulic diameter, m

- I :

-

Currency, A

- h :

-

Heat transfer coefficient, W/m2 K

- k air :

-

Thermal conductivity of air, W/m K

- M :

-

Number of parameters that affect the result

- N :

-

Noise

- n :

-

repeated number of the experiments

- Nu :

-

Nusselt number

- q :

-

Heat flux, W/m2

- Q :

-

Heat transfer rate, W

- P :

-

Spacing between two dimples, m

- R :

-

Result (is generally calculated in some way from the data, \( \hat{X_i} \))

- Re :

-

Reynolds number

- S :

-

Signal

- T jet :

-

Jet exit temperature, K

- T w :

-

Wall temperature, K

- \( \dot{V} \) :

-

Volumetric flow rate of air, m3/s

- V :

-

Voltage, V

- \( \hat{X_i} \) :

-

Parameters affect the results

- yi :

-

experimental results

- ν :

-

Kinematic viscosity of air, m2/s

- ω:

-

Uncertainty

- η:

-

Mean value of S/N

References

Celik N (2011) Effects of the surface roughness on heat transfer of perpendicularly impinging co-axial jet. Heat Mass Transf 47:1209–1217

Celik N, Turgut E (2012) Design analysis of an experimental jet impingement study by using Taguchi method. Heat Mass Transf 48:1407–1413

Caliskan S, Nasiri Khalaji M, Baskaya S, Kotcioglu I (2016) Design analysis of impinging jet array heat transfer from a surface with v-shaped and convergent–divergent ribs by the Taguchi method. Heat Transfer Engineering 37:1252–1266

Yakut R, Yakut K, Yeşildal F, Karabey A (2016) Experimental and numerical investigations of impingement air jet for a heat sink. Procedia Engineering 157:3–12

Shojaeefard MH, Khaneshan VM, Ehteram MA, Akbari M, Allymehr E (2015) Taguchi optimization of micron sized lubricant oil droplet deposition on a hot plate. J Mech Sci Technol 29:3277–3285

Chandramohan P, Murugesan SN, Arivazhagan S (2017) Heat transfer analysis of flat plate subjected to multi-jet air impingement using principal component analysis and computational technique. Journal of Applied Fluid Mechanics 10:293–306

Negi DS, Pattamatta A (2012) Parametric design and optimization for impingement jet heat transfer over dimpled topologies. ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE) 7:1427–1440

Heo MW, Lee KD, Kim KY (2012) Parametric study and optimization of staggered inclined impinging jets on a concave surface for heat transfer augmentation. Numerical Heat Transfer, Part A 61:442–462

Heo MW, Lee KD, Kim KY (2011) Optimization of an inclined elliptic impinging jet with cross flow for enhancing heat transfer. Heat Mass Transf 47:731–742

Song, X., Zhang, J., Kang, S., (...), Cao, W., and Pickert, V., (2014). Surrogate-based analysis and optimization for the design of heat sinks with jet impingement, IEEE Transactions on Components, Packaging and Manufacturing Technologies 4: 429–437

Li HY, Chiang MH, Chen KY (2007) Performance analysis of pin-fin heat sinks with confined impingement cooling. IEEE Transactions on Components and Packaging Technologies 30:383–389

Juraeva M, Song DJ, Kang DJ (2019) Computational optimization approach to design a water-jet nozzle for a water-jet loom using the design of experiment method. J Mech Sci Technol 33:631–637

Shi J, Wang Z, Zhou L, Zhang X (2019) Numerical investigation on a new concept of shock vector control nozzle. J Eng Gas Turbines Power 141:091004

Du, J., Li, Y. Li, Z. Li, J. Wang, Z. Zhang, H. (2019). Performance enhancement of industrial high loaded gas compressor using Coanda jet flap. Energy. 618–629

Li L, Lv X, Zhang L, Li D (2018). Application of Optimization Method in the Design of Shock Vector Control Nozzle. Journal of Physics: Conference Series. 1087: code 052014

Heydrich M, Hammami A, Choudhary S, Mockel M, Ratulowski J (2019). Impact of a novel coating on inorganic scale deposit growth and adhesion. Proceedings of the Annual Offshore Technology Conference, Houston; USA; Code 148087

Saiful CG, Cheng K, Sun X, Bateman R (2012) Optimizing heat transfer rate in an internally cooled cutting tool: FE-based design analysis and experimental study. Key Eng Mater 496:188–193

Lee CY, Fang CJ, Peng CH, Lin TW, Hung YH (2007) Heat transfer characteristics for a confined rotating MCM disk with round jet array impingement. Proceedings of the ASME InterPack Conference 2:909–916

Chauhan R, Singh T, Kumar N, Patnaik A, Thakur NS (2017) Experimental investigation and optimization of impinging jet solar thermal collector by Taguchi method. Appl Therm Eng 116:100–109

Kumar S, Linehan B, Tseng YC (2014) A new combination approach of CI jet and QESD to formulate pH-susceptible amorphous solid dispersions. Int J Pharm 466:368–374

Hannat R, Morency F, Decoster L (2013) Numerical study of a hot-air-based aircraft wing anti-icing system using the box-behnken DoE approach. Trans Can Soc Mech Eng 37:111–128

Larraona GS, Rivas A, Antón R, Ramos JC, Pastor I, Moshfegh B (2013) Computational parametric study of an impinging jet in a cross-flow configuration for electronics cooling applications. Appl Therm Eng 52:428–438

Cirillo F, Isopi GM (2009) Glass tempering heat transfer coefficient evaluation and air jets parameter optimization. Appl Therm Eng 29:1173–1179

Anderson AM, Chapin DM (2002) The effects of dimpled surface geometry on heat transfer in an impinging jet flow. ASME International Mechanical Engineering Congress and Exposition 2:73–79

Bayazit Y, Sparrow EM (2010) Energy efficiency comparison of forced-air versus resistance heating devices for perioperative hypothermia management. Energy. 35:1211–1215

Kline J, McClintock FA (1953) Describing uncertainties in single-sample experiments. Mech Eng 75:3–8

Fisher RA (1925). Statistical Methods for Research Workers. Oliver and Boyd (Edinburgh). ISBN 0–05–002170-2

Taguchi G, Konishi S (1987). Taguchi Methods, orthogonal arrays and linear graphs, tools for quality American supplier institute, American Supplier Institute. 8–35

Roy RK (2001). Design of Experiments Using The Taguchi Approach, Wiley, ISBN: 978–0–471-36101-5

Foster WT (2000). Basic Taguchi design of experiments, National Association of Industrial Technology Conference, Pittsburgh, PA

Montgomery DC (1997) Design and analysis of experiments, 5th edn. John Wiley & Sons, New York

Ross PJ (1996) Taguchi techniques for quality engineering, 5th edn. McGraw-Hill, New York

Katti V, Prabhu SV (2008) Experimental study and theoretical analysis of local heat transfer distribution between smooth flat surface and impinging air jet from a circular straight pipe nozzle. Int J Therm Sci 51:4480–4495

Lytle D, Webb BW (1994) Air jet impingement heat transfer at low nozzle spacing. International Journal of Heat Mass Transfer 37:1687–1697

Gao N, Sun H, Ewing D (2003) Heat transfer to impinging round jets with triangular tabs. International Journal of Heat Mass Transfer. 46:2557–2569

Vinze R, Chandel S, Limaye MD, Prabhu SV (2016) Influence of jet temperature and nozzle shape on the heat transfer distribution between a smooth plate and impinging air jets sciences. International Journal of Thermal Science 99:136–151

Beitelmal AH, Saad MA, Patel CD (2000) Effects of surface roughness on the average heat transfer of an impinging air jet. International Communications in Heat and Mass Transfer 27:1–12

Kim WH, Park TS (2013) Effects of noncircular inlet on the flow structures in turbulent jets. J Applied Mathematics Physics 6:37–42

Acknowledgements

I would like to thank Professor Ephraim M. Sparrow from University of Minnesota for contributing the temperature measurements with his respectful ideas.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Celik, N. Effects of dimples’ arrangement style of rough surface and jet geometry on impinging jet heat transfer. Heat Mass Transfer 56, 339–354 (2020). https://doi.org/10.1007/s00231-019-02714-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02714-x