Abstract

Anaerobic digestion of sludge is considered to be one of the most appropriate technologies for energy production via conversion of organic matter into methane containing biogas. Biogas produced by anaerobic digestion of municipal wastewater sludge can be utilized as fuel to offset heat and electricity consumption of wastewater treatment facilities. Modeling can be used effectively to evaluate the impact of different process and operation variables on the performance of the treatment processes including complex ones such as anaerobic digestion. Therefore, the Anaerobic Digestion Model No. 1 (ADM1) was applied in order to evaluate the performance of a full-scale anaerobic sludge digester in this study. With the calibration of the most sensitive parameters used in the ADM1, model outputs corresponded well with the measured data obtained from the operation of the full-scale digester. The model was validated with the data acquired from the same anaerobic digester at a different operation period (360 days) and simulation results successfully predicted the digester performance. The overall results of this study demonstrated that the ADM1 can be used as a very useful tool to simulate the digestion of mixed sludge generated from full-scale wastewater treatment plants under mesophilic conditions.

Similar content being viewed by others

Introduction

Due to rapid industrialization, increase in population, and growing concerns over climate change and energy security, renewable energy has attracted strong interest recently (Xin et al. 2018). Energy supply from renewable energy sources has improved remarkably; however, its contribution to global energy mix is still quite limited (Ersahin et al. 2011). Therefore, development of sustainable energy supplies is necessary (Guldhe et al. 2017). In this context, municipal wastewater and sludge, as energy intensive materials, are being recognized as promising feedstocks for energy production (Shizas and Bagley 2004; Gyobu et al. 2015; Korth et al. 2017). Annual sludge production is expected to increase rapidly in the future due to increasing urbanization that requires a higher level of sanitation through stringent environmental regulations to protect the quality of receiving water bodies (Leblanc et al. 2008; Pilli et al. 2015). Municipal wastewater treatment plants employ several types of processes for sludge management such as aerobic and anaerobic stabilization, and incineration (Jimenez et al. 2015). Amongst various alternatives, anaerobic digestion of sludge is considered as one of the most suitable technologies for renewable energy production via the conversion of organic matter into methane containing biogas.

Methane-rich biogas produced by anaerobic digestion of municipal wastewater sludge can be utilized as a fuel to offset heat and electricity consumption of the wastewater treatment facilities. Wan et al. (2016) reported that around 78% of the total energy in wastewater treatment plants could be potentially recovered by anaerobic digestion of primary sludge. It is possible to obtain 12.5 m3 biogas/population equivalent (PE) annually by anaerobic digestion of sludge in a full-scale wastewater treatment plant. By this way, around 23.5 kWh/PE year of energy could be produced (Jenicek et al. 2013). By utilizing all biogas produced by anaerobic sludge digestion via combined heat-power (CHP) units having 34% electric efficiency, 20.6 kWh/PE year of electrical energy was produced in a full-scale wastewater treatment plant (Nowak et al. 2011). Maximization of sludge production in the primary treatment stage of a municipal wastewater treatment plant would serve as a key to achieve the concept of energy-neutral or energy-positive wastewater treatment that has been gaining interest recently (Meerburg et al. 2016; Guven et al. 2017). Together with the optimization of the activated sludge processes via efficient aeration technologies and strategies, anaerobic digestion of biosolids is one of the most important processes to achieve energy autonomy in wastewater treatment plants. For instance; application of a high rate activated sludge process to shunt as much organic matter as possible to sludge stream without oxidation, electricity production of higher than 100% of the demand of a wastewater treatment plant could be produced via biogas from anaerobic digestion of the sludge (Nowak et al. 2011). It was reported that electric energy of 28 kWh/PE year was produced by anaerobic digestion of sludge produced from a high rate activated sludge process (Meerburg et al. 2016). Beside CHP units, other methods such as use of biomethane as biofuel for vehicles after appropriate pre-treatment can be applied to utilize the energy content of biogas (Tilche and Galatola 2008; Ersahin et al. 2011).

Especially to evaluate the impact of different process and operation variables on the performance of the treatment methods, including complex reactions such as anaerobic digestion, modeling can be used as a very effective tool (Shang et al. 2005; Vavilin et al. 2006; Ersahin et al. 2007; Ekama 2009). Modeling has been widely used for understanding, design and control of the waste(water) treatment processes. Over the years, various models, from simple ones that considered anaerobic digestion as only a single step process to advanced and extended complex models, have been developed (Donoso-Bravo et al. 2011; Lauwers et al. 2013). Anaerobic Digestion Model No. 1 (ADM1), has been released by the International Water Association (IWA) task group to aggregate the scientific knowledge on anaerobic bioprocesses and harmonize the modeling studies. Therefore, ADM1 has established a basic platform for modeling of anaerobic digestion and is now considered as the most accepted and widely used model (Batstone et al. 2002a). Various steps are included in the ADM1 covering disintegration, hydrolysis, acidogenesis, acetogenesis and methanogenesis as biochemical, and ion association/dissociation and gas–liquid transfer as physicochemical steps. Ever since its development, ADM1 has been used for simulating anaerobic digestion of different waste(water)s, such as industrial wastewaters (Ersahin et al. 2007; Dereli et al. 2010; Barrera et al. 2015), domestic wastewaters (Feng et al. 2006), agricultural wastes (Gali et al. 2009; Nordlander et al. 2017), and municipal wastewater sludge (Blumensaat and Keller 2005; Yasui et al. 2008; Astals et al. 2013; Lauwers et al. 2013; Mendes et al. 2015; Otuzalti and Altınay Perendeci 2018).

This study attempts to model the dynamic performance of a full-scale anaerobic digester treating mixed sludge (primary and secondary) in a wastewater treatment plant by using ADM1. The model was calibrated and validated, based on effluent chemical oxygen demand (COD), methane production, alkalinity and pH parameters, with the long-term operational data of the full-scale digester. The applications of ADM1 to full-scale sludge digesters are quite limited in literature due to several reasons such as data availability and accessibility. Therefore, the study presents a real-world example of implementation of ADM1 to simulate the long-term dynamic performance of a full-scale sludge digester.

Materials and methods

Full-scale digester

The operational data used in the modeling study were obtained from a full-scale anaerobic sludge digester located in a municipal wastewater treatment plant with a design capacity of 400,000 m3/day corresponding to 1,600,000 PE. The wastewater treatment plant is configured as a 5-stage Bardenpho Process for biological nitrogen and phosphorus removal and operated as an extended aeration process with a high solids retention time (SRT) of around 20 days. The primary sludge and waste activated sludge (the excess activated sludge produced by the biological conversion, which should be removed from the system in order to maintain the required SRT) are anaerobically digested in six flow-through digesters operated in parallel under mesophilic conditions (35–37 °C). Each digester has an effective volume of 10,000 m3 and is mixed with a gas and digestate recirculation systems. The digesters were fed with mixed primary and secondary sludge with an average volumetric loading rate of 1.45 kg COD/m3 day. The hydraulic retention time for the digesters were 32 days and average COD removal efficiency was 33%.

Due to biological growth (and solids present in the raw wastewater which are only partly degraded), excess sludge eventually accumulates beyond the desired MLSS concentration in the aeration tank. This amount of solid (called waste activated sludge, WAS) is removed from the treatment process to keep the ratio of biomass to food supplied (sewage or wastewater) in balance and the F:M ratio in a defined range. WAS is stored away from the main treatment process in storage tanks and is further treated by digestion, either under anaerobic or aerobic conditions prior to disposal.

The operational parameters monitored during the study period were determined according to the Standard Methods (APHA 2005).

Mathematical model

ADM1 is a mathematical model developed by the International Water Association (IWA) task group for mainly describing the biochemical processes involved in anaerobic digestion (Batstone et al. 2002b, 2006). The ADM1 was implemented in Aquasim 2.1g software (Reichert et al. 1998) in this study. The digester was modelled as a continuous system including a mixed liquid reactor with a gas diffusion link to a mixed gas headspace. Initial stoichiometric and kinetic coefficients were taken from the original ADM1 model (Batstone et al. 2002b). Initial concentrations of the state variables were obtained by running the model with constant flow and pollutant load until reaching a steady state. Following that, the model was calibrated with dynamic loading in order to get a similar trend between operational data (200 days) and model prediction. In the complex mathematical models for biological processes, such as ADM1; several parameters with uncertain values, and relatively few measured outputs are involved in simulating the anaerobic digestion process, which in return makes them quite difficult to calibrate. Calibration was performed by using an iterative approach as suggested by Dereli et al. (2010). The calibration procedure was started with the initial parameter values (generally default parameter set) of the model. Simulations were performed by changing the value (depending on the sensitivity and variability) of only one parameter at each trial. The calculated results were compared with the measured data and the difference between the model outputs and data were iteratively minimized based on some statistical indicators. In this approach, kinetic parameters were calibrated by minimizing the root mean square error between measurements and calculated model results. Attempts to quantify all the parameters and coefficients and fit all the parameters simultaneously are not practical and usually result in a very low confidence in the estimated parameters. ADM1 is a highly parameterized model that contains several state variables, biochemical processes, stoichiometric and kinetic parameters (Batstone et al. 2002b). When ADM1 was implemented for sludge digestion, it was reported that disintegration rate of particulates, growth kinetics of acetogenotrophic and hydrogenotrophic methanogens and propionate utilizers were the most sensitive parameters on model outputs (Mendes et al. 2015; Montecchio et al. 2017). Therefore, only a limited number of parameters that have high impact on the results should be calibrated (Dochain and Vanrolleghem 2001; Poggio et al. 2016). In order to testify the accuracy and the predictive ability of the model, a validation study was performed by comparing the data obtained from a different operation period (360 days) to the calibrated model predictions.

Results and discussion

Model calibration

The calibration study was performed with the data obtained from the full-scale digester for a period of 200 days. A brief statistical evaluation of the data is presented in Table 1. During the period of the calibration, the digester was operated with a hydraulic retention time (HRT) of 40 days. The average volumetric loading rate (VLR) and COD removal efficiency of the digester were 1.32 kg COD/m3 day and 34%, respectively. The low COD removal efficiency of the digester was attributed to pre-stabilization of the secondary sludge in the main stream wastewater treatment plant operated as an extended aeration process with a high SRT. This situation was taken into account for ADM1 based COD fractionation of the composite matter (Table 2). Thus, the particulate inert fraction of substrate was increased to 49% indicating a low biodegradability. Astals et al. (2013) reported that particulate inert fraction of municipal wastewater sludge varied between 38 and 46% depending on the type of sludge and operating conditions of the treatment plant. Besides, high values for particulate inert fraction of waste activated sludge, over 40%, were reported in the study of Lubken et al. (2015). In order to ensure carbon and nitrogen balances in ADM1, the carbon and nitrogen content of the particulate organic matter was adjusted based on the influent characteristics according to Eqs. 1 and 2 (Ersahin et al. 2007; Gernaey et al. 2014). Balance of nitrogen and carbon contents is quite significant for a successful simulation of anaerobic digestion process (Ronner-Holm et al. 2012).

where CXC: carbon content of the composites, Cinert: carbon content of the inerts, Caa: carbon in amino acids and proteins, Csu: carbon in sugars, Cli: carbon in lipids, NXC: nitrogen content of the composites, Ninert: nitrogen content of the inerts, Naa: nitrogen in amino acids and proteins.

Anaerobic digestion is a very complex process comprising of several stages such as disintegration and hydrolysis of particulate organics, acidogenesis, acetogenesis and methanogenesis. In order to mathematically describe the anaerobic decomposition processes, ADM1 uses several kinetic and stoichiometric parameters (Batstone et al. 2002b). The calibration of the ADM1 model parameters requires a deep understanding of the interaction between each process, functional microorganism and environmental conditions. Thus, only the most important parameters should be calibrated to improve the compatibility between measured data and model outputs. A minimum set of parameters, that were reported as the most sensitive parameters on simulation results (Souza et al. 2013; Chen et al. 2015; Barrera et al. 2015), were manually calibrated. The calibrated parameters and their initial values are given in Table 3. Disintegration rate of particulates, fractionation of particulate organics and kinetics of acetate, propionate and hydrogen utilizers were changed to fit the model outputs to the experimental results data. The disintegration rate is of particular importance when modeling the anaerobic digestion of waste activated sludge since disruption of bacteria cells and release of biodegradable organic matter is the rate limiting step in the process (Ramirez et al. 2009). The rest of the parameters were used as original ADM1 defaults (Batstone et al. 2002b).

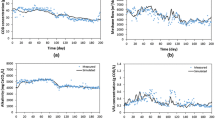

The simulation results obtained in the calibration study are depicted in Fig. 1. Figure 1 showed simulated and measured results of effluent COD, methane production, alkalinity and pH after calibration of the model. The dynamic performance of the digester in terms of the investigated parameters was simulated in good agreement with the measured data. Fluctuations in the alkalinity, and the variations in methane production in the first 100 days were predicted with the model quite reasonably. Methane production was slightly over predicted, especially between 100 and 200th days. This may be related with the changing sludge characteristics since the primary and waste activated sludge composition varied significantly due to several reasons such as changes in wastewater characteristics and mainstream treatment plant operation. This is reported as one of the most important difficulties in calibrating ADM1 since it requires an extensive substrate characterization that is not commonly practiced in full-scale reactors (Ozkan-Yucel and Gokçay 2010). Arnell et al. (2016) reported that biodegradable fraction of COD, and protein and lipid fractions of particulate biodegradable COD had significant effect on methane production and digester stability. Interactions between water and sludge streams and the dynamics in a wastewater treatment plant could be better simulated by plant-wide modeling as suggested by Mbamba et al. (2016).

Model validation

Evaluation of the agreement of the model responses with a different data set was performed in the validation study. The calibrated model was validated with a data set belonging to a different operation time (360 days), which was not used for the calibration study. During this period, the average HRT and VLR of the digester were 28 days and 1.63 kg COD/m3 day, respectively. Statistical evaluation of the data used for model validation is given in Table 4.

The validation outputs and the measured data for effluent COD, methane production, alkalinity and pH parameters are presented in Fig. 2. In general, the calibrated model reasonably predicted the dynamic behavior of the full-scale anaerobic sludge digester in the validation period. The model could match the pH value in good agreement with the measured data. The mean absolute relative error for pH prediction was calculated as 1.9%, which can be regarded as high accuracy (Batstone and Keller 2003). However, the alkalinity in the digester was slightly overpredicted possibly due to overestimated cation concentrations in the influent. Better prediction of pH in comparison to alkalinity parameter was also reported by Derbal et al. (2009). Since alkalinity was more sensitive than pH, it was suggested to use alkalinity as a control parameter for operation of anaerobic digesters. Although the model could predict the dynamic profile of methane generation, there were some deviations from the measured data. These discrepancies might be due to the changes in the sludge composition fed to the digester. The mean absolute relative errors for COD, methane flow, and alkalinity predictions were calculated as 12.6%, 23.9, and 13.8, respectively; which can be regarded as medium accuracies (Batstone and Keller 2003). The biodegradability of the sludge, in particular inert fraction (fxI,xc), is strongly dependent on the operational SRT of the activated sludge systems (Jones et al. 2009). Mottet et al. (2010) reported that the waste activated sludge from extended aeration systems contained more lignin-, cellulose- and hemicellulose-“like” fractions than the sludge from treatment systems operated at short SRTs. Thus, the over- and underpredicted results might be related with the differences in the stabilization degree of the waste activated sludge in the mainstream wastewater treatment plant during calibration and validation periods.

Anaerobic digestion of municipal sludge and biogas derived electricity production are crucial for improving the degree of energy self-sufficiency in municipal wastewater treatment plants. It is reported that the average biogas production of anaerobic digesters and self-supply of electricity of wastewater treatment plants in Germany are 26 L/PE day and 40%, respectively (DWA-A 216E 2015). The specific biogas production in the investigated full-scale digesters was calculated as 12 ± 4 L/PE day, which was remarkably low. Therefore, there seems to be an important potential for optimization of both main stream wastewater treatment process and anaerobic sludge digestion. Thus, modeling can serve as a valuable tool to improve the process performance and degree of energy self-sufficiency of the plant. For instance; positive impact of co-digestion approach on methane production and total operational cost of an anaerobic digester was presented by the plant-wide simulation study of Arnell et al. (2016).

Conclusions

ADM1 model was employed to describe the anaerobic digestion of mixed (primary and secondary) sludge from a municipal wastewater treatment plant under mesophilic conditions in a full-scale anaerobic digester. According to the statistical evaluation of the data obtained from the digester, the average COD removal efficiency was only 33%, which was quite low considering the high HRT (32 days) of the digester. This was related with the pre-stabilization of the secondary sludge in the main stream wastewater treatment plant operated as an extended aeration process. With the calibration of the most sensitive parameters, the model simulation outputs corresponded well with the measured data. The model was validated with the data acquired from a different operation period and it predicted the process performance reasonably well, especially in terms of effluent COD and pH. Some deviations observed in methane generation were attributed to the changes in the sludge composition depending on the stabilization degree of the waste activated sludge in the mainstream wastewater treatment plant. The overall results of this study demonstrated that the ADM1 model can be used as a useful tool to simulate the dynamic performance of the full-scale sludge digesters. Thus, it can be used as a tool to optimize sludge digesters in order to achieve more energy autonomous and sustainable municipal wastewater treatment plants.

References

APHA (2005) Standard methods for examination of water and wastewater. American Public Health Association, Washington

Arnell M, Astals S, Amand L, Batstone DJ, Jensen PD, Jeppsson U (2016) Modelling anaerobic co-digestion in Benchmark Simulation Model No. 2: parameter estimation, substrate characterisation and plant-wide integration. Water Res 98:138–146

Astals S, Esteban-Gutierrez M, Fernandez-Arevalo T, Aymerich E, Garcia-Heras JL, Mata-Alvarez J (2013) Anaerobic digestion of seven different sewage sludges: a biodegradability and modelling study. Water Res 47:6033–6043

Barrera EL, Spanjers H, Solon K, Amerlinck Y, Nopens I, Dewulf J (2015) Modeling the anaerobic digestion of canemolasses vinasse: extension of the Anaerobic Digestion Model No. 1 (ADM1) with sulfate reduction for a very high strength and sulfate rich wastewater. Water Res 71:42–54

Batstone DJ, Keller J (2003) Industrial applications of the IWA anaerobic digestion model No. 1 (ADM1). Water Sci Technol 47(12):199–206

Batstone DJ, Keller J, Angelidaki I, Kalyuzhnyi SV, Pavlostathis SG, Rozzi A, Sanders WTM, Siegrist H, Vavilin VA (2002a) The IWA Anaerobic Digestion Model No. 1 (ADM1). Water Sci Technol 45(10):65–73

Batstone DJ, Keller J, Angelidaki I, Kalyuzhnyi SV, Pavlostathis SG, Rozzi A, Sanders WTM, Siegrist H, Vavilin VA (2002b) Anaerobic digestion model No. 1, scientific and technical report No. 13. IWA Publishing, London

Batstone DJ, Keller J, Steyer JP (2006) A review of ADM1 extensions, applications, and analysis: 2002–2005. Water Sci Technol 54(4):1–10

Blumensaat F, Keller J (2005) Modeling of a two-stage anaerobic digestion using the IWA Anaerobic Digestion Model No. 1 (ADM1). Water Res 39(1):171–183

Chen Y, He J, Mu Y, Huo Y-C, Zhang Z, Kotsopoulos TA, Zeng RJ (2015) Mathematical modeling of upflow anaerobic sludge blanket (UASB) reactors: simultaneous accounting for hydrodynamics and bio-dynamics. Chem Eng Sci 137:677–684

Derbal K, Bencheikh-lehocine M, Cecchi F, Meniai A-H, Pavan P (2009) Application of the IWA ADM1 model to simulate anaerobic co-digestion of organic waste with waste activated sludge in mesophilic condition. Bioresour Technol 100:1539–1543

Dereli RK, Ersahin ME, Ozgun H, Ozturk I, Aydin AF (2010) Applicability of Anaerobic Digestion Model No 1 (ADM1) for a specific industrial wastewater: opium alkaloid effluents. Chem Eng J 165(1):89–94

Dochain D, Vanrolleghem P (2001) Dynamical modelling and estimation in wastewater treatment processes. IWA Publishing, London

Donoso-Bravo A, Mailier J, Martin C, Rodriguez J, Aceves-Lara C, Wouwer AV (2011) Model selection, identification and validation in anaerobic digestion: a review. Water Res 45(17):5347–5364

DWA-A 216E (2015) Energy check and energy analysis instruments to optimise the energy usage of wastewater systems. German Association for Water, Wastewater and Waste (DWA), Hennef

Ekama GA (2009) Using bioprocess stoichiometry to build a plant-wide mass balance based steady-state WWTP model. Water Res 43:2101–2120

Ersahin ME, Insel G, Dereli RK, Ozturk I, Kinaci C (2007) Model based evaluation for the anaerobic treatment of corn processing wastewaters. Clean-Soil Air Water 35(6):576–581

Ersahin ME, Gomec CY, Dereli RK, Arikan O, Ozturk I (2011) Biomethane production as an alternative bioenergy source from codigesters treating municipal sludge and organic fraction of municipal solid wastes. J Biomed Biotechnol. https://doi.org/10.1155/2011/953065

Feng Y, Behrendt J, Wendland C, Otterpohl R (2006) Implementation of the IWA anaerobic digestion model No. 1 (ADM1) for simulating digestion of blackwater from vacuum toilets. Water Sci Technol 53(9):253–263

Gali A, Benabdallah T, Astals S, Mata-Alvarez J (2009) Modified version of ADM1 model for agro-waste application. Bioresource Technol 100:2783–2790

Gernaey KV, Jeppson U, Vanrolleghem PA, Copp JB (2014) Benchmarking of control strategies for wastewater treatment plants, scientific and technical report series No. 23. IWA Publishing, London

Guldhe A, Kumari S, Ramanna L, Ramsundar P, Singh P, Rawat I, Bux F (2017) Prospects, recent advancements and challenges of different wastewater streams for microalgal cultivation. J Environ Manag 203:299–315

Guven H, Ersahin ME, Dereli RK, Ozgun H, Sancar D, Ozturk I (2017) Effect of hydraulic retention time on the performance of high rate activated sludge system: a pilot-scale study. Water Air Soil Pollut 228(417):1–10

Gyobu T, Inoue M, Soda S, Ike M (2015) Energy content of organics in municipal wastewater treatment streams at Tsumori Wastewater Treatment Plant. J Water Environ Technol 13(1):89–97

Jenicek P, Kutil J, Benes O, Todt V, Zabranska J, Dohanyos M (2013) Energy self-sufficient sewage wastewater treatment plants: is optimized anaerobic sludge digestion the key? Water Sci Technol 68(8):1739–1744

Jimenez J, Miller M, Bott C, Murthy S, Clippeleir HD, Wett B (2015) High-rate activated sludge system for carbon management—evaluation of crucial process mechanisms and design parameters. Water Res 87:476–482

Jones R, Parker W, Zhu H, Houweling D, Murthy S (2009) Predicting the degradability of waste activated sludge. Water Environ Res 81(8):765–771

Korth B, Maskow T, Günther S, Harnisch F (2017) Estimating the energy content of wastewater using combustion calorimetry and different drying processes. Front Energ Res. https://doi.org/10.3389/fenrg.2017.00023

Lauwers J, Appels L, Thompson IP, Degreve J, Van Impe JF, Dewil R (2013) Mathematical modelling of anaerobic digestion of biomass and waste: power and limitations. Prog Energ Combust 39:383–402

LeBlanc RJ, Matthews P, Richard RP (2008) Global atlas of excreta, wastewater sludge, and biosolids management: moving forward the sustainable and welcome uses of a global resource. United Nations Human Settlements Programme (UN-HABITAT), Nairobi, Kenya

Lubken M, Kosse P, Koch K, Gehring T, Wichern M (2015) Influent fractionation for modeling continuous anaerobic digestion processes. In: Scheper T (ed) Biogas science and technology. Springer International Publishing, Switzerland, pp 137–169

Mbamba CK, Flores-Alsina X, Batstone DJ, Tait S (2016) Validation of a plant-wide phosphorus modelling approach with minerals precipitation in a full-scale WWTP. Water Res 100:169–183

Meerburg FA, Boon N, Winckel TV, Pauwels KTG, Vlaeminck SE (2016) Live fast, die young: optimizing retention times in high-rate contact stabilization for maximal recovery of organics from wastewater. Environ Sci Technol 50(17):9781–9790

Mendes C, Esquerre K, Queiroz LM (2015) Application of Anaerobic Digestion Model No. 1 for simulating anaerobic mesophilic sludge digestion. Waste Manag 35:89–95

Montecchio D, Braguglia CM, Gallipoli A, Gianico A (2017) A model-based tool for reactor configuration of thermophilic biogas plants fed with waste activated sludge. Renew Energ 113:411–419

Mottet A, François E, Latrille E, Steyer JP, Déléris S, Vedrenne F, Carrère H (2010) Estimating anaerobic biodegradability indicators for waste activated sludge. Chem Eng J 160(2):488–496

Nordlander E, Thorin E, Yan J (2017) Investigating the possibility of applying an ADM1 based model to a full-scale co-digestion plant. Biochem Eng J 120:73–83

Nowak O, Keil S, Fimml C (2011) Examples of energy self-sufficient municipal nutrient removal plants. Water Sci Technol 64(1):1–6

Otuzalti MM, Altınay Perendeci N (2018) Modeling of real scale waste activated sludge anaerobic digestion process by Anaerobic Digestion Model 1 (ADM1). Int J Green Energy 15(7):454–464

Ozkan-Yucel UG, Gokçay CF (2010) Application of ADM1 model to a full-scale anaerobic digester under dynamic organic loading conditions. Environ Technol 31(6):633–640

Pilli S, More T, Yan S, Tyagi RD, Surampalli RY (2015) Anaerobic digestion of thermal pre-treated sludge at different solids concentrations—computation of mass-energy balance and greenhouse gas emissions. J Environ Manag 157:250–261

Poggio D, Walker M, Nimmo W, Ma L, Pourkashanian M (2016) Modelling the anaerobic digestion of solid organic waste—substrate characterisation method for ADM1 using a combined biochemical and kinetic parameter estimation approach. Waste Manag 53:40–54

Ramirez I, Mottet A, Carrère H, Déléris S, Vedrenne F, Steyer J-P (2009) Modified ADM1 disintegration/hydrolysis structures for modeling batch thermophilic anaerobic digestion of thermally pretreated waste activated sludge. Water Res 43(14):3479–3492

Reichert P, Ruchti J, Simon W (1998) Aquasim 2.0. Swiss Federal Institute for Environmental Science and Technology (EAWAG), Duebendorf

Ronner-Holm SGE, Zak A, Holm NC (2012) Comparison of different conditions, substrates and operation modes by dynamic simulation of a full-scale anaerobic SBR plant. Water Sci Technol 65(3):558–566

Shang Y, Johnson BR, Sieger R (2005) Application of the IWA Anaerobic Digestion Model (ADM1) for simulating full-scale anaerobic sewage sludge digestion. Water Sci Technol 52(1–2):487–492

Shizas I, Bagley DM (2004) Experimental determination of energy content of unknown organics in municipal wastewater streams. J Energ Eng 130(2):45–53

Souza TSO, Carvajal A, Donoso-Bravo A, Pena M, Fdz-Polanco F (2013) ADM1 calibration using BMP tests for modeling the effect of autohydrolysis pretreatment on the performance of continuous sludge digesters. Water Res 47:3244–3254

Tilche A, Galatola M (2008) The potential of bio-methane as bio-fuel/bio-energy for reducing greenhouse gas emissions: a qualitative assessment for Europe in a life cycle perspective. Water Sci Technol 57(11):1683–1692

Vavilin VA, Jonsson S, Ejlertsson J, Svensson BH (2006) Modelling MSW decomposition under landfill conditions considering hydrolytic and methanogenic inhibition. Biodegradation 17:389–402

Wan J, Gu J, Zhao Q, Liu Y (2016) COD capture: a feasible option towards energy self-sufficient domestic wastewater treatment. Sci Rep 6:25–26. https://doi.org/10.1038/srep25054

Xin C, Addy MM, Zhao J, Cheng Y, Ma Y, Liu S, Mu D, Liu Y, Chen P, Ruan R (2018) Waste-to-biofuel integrated system and its comprehensive techno-economic assessment in wastewater treatment plants. Bioresour Technol 250:523–531

Yasui H, Goel R, Li YY, Noike T (2008) Modified ADM1 structure for modelling municipal primary sludge hydrolysis. Water Res 42:249–259

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ozgun, H. Anaerobic Digestion Model No. 1 (ADM1) for mathematical modeling of full-scale sludge digester performance in a municipal wastewater treatment plant. Biodegradation 30, 27–36 (2019). https://doi.org/10.1007/s10532-018-9859-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-018-9859-4