Abstract

Background

In this study, the photodegradation of three pharmaceuticals, namely Ibuprofen (IBP), Naproxen (NPX), and Cetirizine (CIZ) in aqueous media was investigated under UV irradiation. The photocatalyst used in this work consists of surface functionalized titanium dioxide (TiO2–NH2) nanoparticles grafted into Polyacrylonitrile (PAN)/multi-walled carbon nanotube composite nanofibers. Surface modification of the fabricated composite nanofibers was illustrated using XRD, FTIR, and SEM analyses.

Results

Sets of experiments were performed to study the effect of pharmaceuticals initial concentration (5–50 mg/L), solution pH (2–9), and irradiation time on the degradation efficiency. The results demonstrated that more than 99% degradation efficiency was obtained for IBP, CIZ, and NPX within 120, 40, and 25 min, respectively.

Conclusions

Comparatively, the photocatalytic degradation of pharmaceuticals using PAN-CNT/TiO2–NH2 composite nanofibers was much more efficient than with PAN/TiO2–NH2 composite nanofibers.

Similar content being viewed by others

Introduction

Nowadays, the world recognizes the importance of the continuous development on the area of synthesis and production of a variety of pharmaceutical drugs for both humans and animals. Large scales of different chemical compounds are used as medicinal products. These compounds classified as emerging pollutants, while their essential passage into the environment is pharmaceutical industries, excretory products of medically treated humans and animals, which followed by their inefficient removal in wastewater treatment plants [1, 2]. Also they enter to the environment after inappropriate disposal of expired pharmaceutical products in the sewage system or in the garbage. The extended usage of dangerous pharmaceuticals is followed by an increased pollution of ground, surface, and drinking water by these compounds [3, 4].

The most considerably detected groups of pharmaceuticals in the environment are Non-steroidal anti-inflammatory drugs (NSAIDs). These are one of the widely available drugs in the world. NSAID group have a main common characteristic, which is the carboxylic aryl acid moiety, which provides their acidic properties. Ibuprofen (IBP) belongs to this family of pharmaceuticals, which is an analgesic drug highly used for the medicament of myoskeletal injuries, rheumatoid arthritis, and fever [5]. A large number of NSAIDs are widely existing in surface water, these contaminations are highly problematic because the surface waters are main resources used for drinking water production. Choina et al. [6], studied the degradation of the IBP and the results indicated that the photocatalytic treatment with titania catalyst leads to rapid mineralization of ibuprofen. NPX also belongs to the non-steroidal anti-inflammatory drug (NSAID) [7]. In addition, NPX is used as an antipyretic and analgesic drug for the treatment of rheumatoid arthritis. In addition, it is also used as veterinary medicine [8]. Ray et al. [9], studied the degradation of the NPX over AgBr-α-NiMoO4 composite photocatalyst and the results show that the composite photocatalyst degraded NPX drug rapidly within 20 min under visible light irradiation. The photocatalytic performances of composite stayed efficient up to fifth cycle, and this indicates to the excellent stability [10, 11]. Moreover, CIZ append to the piperazine class of second generation antihistamines used in the treatment of allergies, hay fever, angioedema, and urticarial and causes various side effects such as dry mouth, sleepiness, sedation, fatigue, fever, stomach upset, and blurred vision when ingested accidentally to the human body [12]. The degradation of CIZ has not reported neither by enzymatic method nor by ultrasound assisted enzymatic method. Rahul et al. [13], studied the degradation of the CIZ using a novel technique of laccase enzyme as a catalyst under the influence of ultrasound irradiation. The results show that the degradation of CIZ achieved was 91% in comparison of ultrasound assisted enzymatic degradation with conventional at a shorter time.

The most conventional treatment processes applied at domestic wastewater treatment plants fail to remove completely pharmaceutical substances. Therefore, the treatment of the polluted water requires the application of effective techniques such as Advanced Oxidation Processes (AOPs) [14, 15]. Among AOPs, photocatalysis is a very important and attractive process. Heterogeneous photocatalytic water treatment has a highly special interest since it doesn’t require the use of any additional chemicals [16, 17]. The photocatalytic processes mainly use semiconducting material catalysts such as (TiO2, Fe2O3, ZnO) under light exposure (UV-light or sunlight) to degrade the organic and inorganic contaminants. Most of the researches are now focusing on the photocatalytic techniques using composite nanofibers [18, 19]. Many semiconducting catalysts can be used, but Titania (TiO2) is the most common semiconducting catalyst used due to its cheap cost combined with a high photocatalytic activity, nonhazardous compound and eco-friendly [20, 21]. The application of Titania catalyst is most attractive for effective photocatalytic degradation of drugs and other harmful organic pollutants assisted by UV–Vis radiation. In this work, PAN nanofibers were used as substrate for holding the photocatalyst material. On the other hand, MWCNTs was used to improve the tensile strength, young’s modulus, and chemical resistance of the nanofiber due to their high physical, and chemical properties [22,23,24]. In addition, CNT may increases the photocatalytic activity of the process due to its electron donor properties. Moreover, it offers the possibility of complete abatement of drugs and can be recovered and re-used [25, 26]. Therefore, the aim of this work was to investigate the photodegradation of IBP, NPX, and CIZ in aqueous media by means of composite nanofibers (PAN-MWCNT/TiO2–NH2) under UV irradiation. The effect of operating conditions such as initial drug concentration, and solution pH were evaluated.

Experimental

Material

TiO2 Degussa P-25, 3-aminopropyltriethoxysilane (APTES), Glutaraldehyde (GA), polyacrylonitrile, PAN (MW = 150,000); dimethylformamide (DMF), hydrochloric acid (HCI), sodium hydroxide (NaOH), Ibuprofen, Naproxen, and Cetirizine were purchased from sigma Aldrich and used as received. Multi-walled carbon nanotubes, MWCNTs (purity 95 wt%; diameter: 10–40 nm; length: 20 μm; specific surface area 460 m2/g) were synthesized and the procedure is described elsewhere [27, 28]. The chemical structures of the pharmaceuticals are presented in Table 1.

Composite nanofibers preparation

A 10 wt% solution of PAN powder in DMF was prepared by mixing 1 g PAN with 9 mL DMF for 4 h at 50 °C. In parallel, 3 wt% surface activated MWCNTs were dispersed in DMF; the dispersion was stirred for 15 min, and then sonicated for 30 min. PAN solution was then added to the MWCNTs. The mixture was magnetically stirred for 15 min and then sonicated for 3 h. The electrospinning process was conducted at room temperature using a voltage of 25 kV, flow rate of 0.5 ml/h, and distance from needle tip to collector was 15 cm [29]. The electrospun PAN/MWCNT nanofibers were dried in vacuum over night to remove the excess amount of solvent. The electrospun composite nanofibers was cross-linked to TiO2–NH2 NPs. The composite nanofibers was then immersed in the crosslinking medium, which consisting of 100 mL distilled water and 2.5 wt% GA and placed in a mechanical shaker for 24 h at the room temperature. After the crosslinking process the composite nanofibers was washed with deionized water. The surface functionalization TiO2–NH2 NPs was suspended in 5 mL deionized water, afterward sonicated for 2 h and then added to the cross-linked composite nanofibers and mixed using mechanical shaker for 24 h. The PAN-CNT/TiO2–NH2 composite nanofibers was finally washed with deionized water and dried in air at the room temperature.

Photocatalyst characterization

The morphology of the composites nanofibers was examined using Scanning Electron Microscopy (SEM, Gemini Zeiss-Ultra 55). Fourier transform infrared spectroscopy (FTIR, Nicolet iS10) was used to confirm the presence of amino groups on the TiO2 NPs attached to the surface of the composite nanofibers. The crystal phases of the composite nanofibers were evaluated by X-ray diffractometry (XRD, Bruker D8) using Cu Kα radiation (λ = 1.5406 Å). The concentration of IBP, NPX, and CTZ in the solution was measured using UV–Vis/NIR spectrophotometer (model LAMBDA 750, Perkin Elmer) at maximum absorption wavelength (λmax) 222 nm, 229 nm and 232 nm for IBP, CTZ, and NPX, respectively.

Degradation experiments

A stock solution of 100 mg/L of each pharmaceutical was prepared by addition of the appropriate amount of the pharmaceutical to 500 mL deionized water. Different drugs concentration (5, 10, 20, 30, and 50 mg/L) at different pH starting from 2 to 9 were prepared using the stock solution. For detection and quantification purposes, the range of concentrations in this study is higher than those typically detected in the environment. Using a UV-A lamp (315–400 nm) of 40 Watts for the UV-light irradiation which, suitable for the photocatalytic process especially whose work with polymer based composite nanofibers. The photocatalytic activity of PAN nanofibers, and composite nanofibers of PAN/TiO2–NH2 and PAN-MWCNT/TiO2–NH2 was studied by recording the degradation of IBP, NPX, and CIZ using UV–Vis spectrophotometer. The photocatalysis experiments were performed by placing the composite nanofibers mat in a column (2 cm × 30 cm) and the drug solution of 100 mL was circulated at a flow rate of 7 mL/min under UV-light irradiation. 5 mL of the drug solution were taken at fixed intervals of time. The solution pH was adjusted between 2 and 9 by the addition of HCl or NaOH. The pH was measured using a pH meter (WTW pH-330, Germany). After each experiment, the composite nanofibers were washed many times using deionized water to be able to reuse. All experiments were duplicated to assure the consistency and reproducibility of the results. The photodegradation efficiency was calculated according to the following equation:

where, Ci (mg/L) is the initial drug concentration and Ct (mg/L) is the drug concentration at time (t).

Results and discussion

Photodegradation performance

Effect of catalyst amount

In order to determine the effect of the photocatalyst amount, a set of experiments were performed by varying the amount of the catalyst from 5 to 30 mg in a total volume of 100 mL and drug concentration of 5 mg/L at pH = 2. Figure 1 illustrates the effect of the photocatalyst amount on the photodegradation efficiency of pharmaceuticals. The results obtained demonstrated that photocatalytic degradation performance was substantially improved with increasing the amount of the photocatalyst and reached a plateau at a dosage of 15 mg (PAN-MWCNT/TiO2–NH2). This may be due to the increased number of active sites on PAN-MWCNT/TiO2–NH2 surface. Consequently, the increased generation of electron–hole pairs on the surface of the catalyst subsequently leading to higher amounts of reactive hydroxyl radicals that can be attributed to the better degradation observed. The increase in MWCNT/TiO2–NH2 loading provides more binding sites for substrate molecules to adsorb on the catalyst surface. In this study the fabricated composite nanofibers with 75% TiO2–NH2 NPs and 25% of MWCNT was used in all experiments.

Effect of exposure time

The photocatalytic degradation was carried under controlled condition using PAN nanofiber, PAN/TiO2–NH2, and PAN-MWCNT/TiO2–NH2 composite nanofibers to illustrate the effect of the catalyst (TiO2–NH2 and MWCNT) on the composite nanofiber. Figure 2 shows the influence of exposure time on the photodegradation efficiency of IBP, NPX, and CIZ under UV-light. As can be observed from the results, the PAN-MWCNT/TiO2–NH2 composite nanofibers showed the highest degradation efficiency for all tested contaminates, which is attributed to the high surface to mass ratio for the composite nanofibers. Additionally, CNTs can effectively generate a number of free electrons and holes, which leads to acceleration of the photocatalytic reaction to enhance the photocatalytic activity. The complete degradation was observed at 120 min for IBP, 40 min for NPX, and 25 min for CIZ.

Effect of drug initial concentration

The photocatalytic degradation efficiency of a certain drug depends on its concentration, nature and on the presence of other existing compounds in the water matrix. Figure 3 shows the effect of IBP, NPX, and CIZ initial concentration on their photodegradation efficiency. The degradation efficiency was studied at initial concentrations of 5, 10, 20, 30, and 50 mg/L. The results obtained indicated that the photodegradation efficiency of IBP, NPX, and CIZ decreased from 100 to 70% as their initial concentration increased from 5 to 50 mg/L. This may be attributed to the decrease of hydroxyl radicals on the catalyst surface as the initial drug concentration is increased. As more drug molecules are adsorbed on the surface of the photocatalyst (MWCNT/TiO2–NH2), less active sites for the adsorption of hydroxyl radicals will be available. Hence, large amounts of adsorbed pharmaceuticals would have an inhibitory influence on the reaction between pharmaceuticals molecules and hydroxyl radicals due to the lack of any direct contact between them. On the other hand, most of the UV-light is absorbed by as the drug molecules as their concentration is increased, and the photons do not reach the surface of photocatalyst to generate hydroxyl radicals [30]. In addition, the photocatalytic degradation reaction will be deactivated due to the saturated surface of the photocatalyst, which caused by the high concentration of the drug.

The Effect of the pH of the solution

The photocatalytic abatement of IBP, NPX, and CIZ over TiO2–NH2 is significantly improved with decreasing pH value. The effect of pH on the degradation efficiency of pharmaceuticals drugs was studied by varying the solution pH from 2 to 9 at fixed catalyst amount of 15 mg and UV-light irradiation time of 120, 40, and 25 min for IBP, NPX, and CIZ, respectively. Figure 4 shows that the acidic conditions showed higher degradation efficiency and the maximum was obtained at pH 2. In a weak acidic medium, the pharmaceutical drugs are electrically neutral and exist in molecular form, while TiO2–NH2 is protonated and electropositive [31, 32]. The efficiency of the process increases by the formation of hydroxyl radicals that formed when the hydroxide ions interact with the positive holes at low pH [33], which attributed due to the electrostatic interactions between the positive catalyst surface and the pharmaceuticals drug anions, leading to strong adsorption of the pharmaceuticals drug anions on the metal oxide support. However, in strong acidic media, TiO2–NH2 is electropositive and the concentration of H+ is excessive, which might lead to the reductions of OH·. As a result, the degradation efficiency of the pharmaceutical drugs was decreased. In neutral and alkaline media, the pharmaceutical drugs are electronegative due to ionization. Therefore, it can repel electronegative TiO2–NH2 and OH− [34].

Nanocomposite stability

The catalyst re-usability examined by cycling experiments under controlled reaction conditions. The reuse of the composite nanofibers is important and has an economic necessity. The PAN-MWCNT/TiO2–NH2 composite nanofibers were used in sequential photocatalytic process to investigate the durability of the catalytic composite nanofibers. The composite nanofibers washed several times with deionized water and then dried in air after each process, in order to reuse it in other experiments. The Photodegradation efficiency of PAN-MWCNT/TiO2–NH2 composite nanofibers remained stable during the first four sequential cycles, then decreased by about 7% in the last cycle as shown in Fig. 5.

Characterization of the composite nanofibers

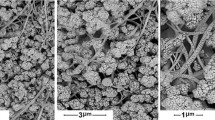

Scanning electron microscope (SEM) analysis was performed to investigate the morphological of the electrospun PAN nanofibers and PAN-MWCNT/TiO2–NH2 composite nanofibers as shown in Fig. 6. It can be seen that the surface morphology of the fabricated composite nanofibers was smooth and continuous with fiber diameters of 251.2 ± 4.6 nm. Figure 6b clearly confirm that the amino functionalized TiO2 NPs are attached to the surface of the PAN/MWCNT nanofibers due to the crosslinking process.

The FTIR spectra of PAN, PAN-CNT, PAN/MWCNT-TiO2 and PAN-MWCNT/TiO2–NH2 composite nanofibers are shown in Fig. 7. The spectrum for as prepared PAN nanofibers exhibited characteristic peaks of nitrile at 2242 cm−1, carbonyl at 1650 cm−1 and C–H stretching at 2940 cm−1 [35]. The spectrum for PAN-CNT composite nanofibers exhibit four peaks at 2342, 1700, 3159, and 1290 cm−1, which are attributed to nitrile, carbonyl, C–H stretching, and C–O–C stretching vibrations of the MWCNT, indicating the existence of PAN-CNT nanofibers [36]. In addition, the vibrational band at 2000–2500 cm−1, is assigned to C ≡ N in the PAN/MWCNT-TiO2 composite nanofibers. The bands observed at 3159, 1520, and 1152 cm−1 are assigned to the aliphatic C–H bending vibration of the CH2 of polymeric chain [37]. The aliphatic C–C band vibrations are observed at 1074 cm−1. After the crosslinking of PAN-MWCNT to TiO2–NH2 NPs, new peaks were observed in the range 3100–3700 cm−1 are assigned to N–H and O–H, and the bending vibrations of the amine group NH or NH2 observed at 1680 cm−1. The band observed at 912 cm−1 is assigned to N–O [38].

In addition, XRD patterns were used to identify the crystal phases of the PAN-CNT/TiO2–NH2 composite nanofibers before and after photocatalysis as shown in Fig. 8. No other impurity diffraction peaks were detected, and the crystal structure is stable after the photocatalytic process. Noticeably, the intensities of the peaks are broad and weak, which indicate that the crystallinity is poor and the crystallite size is small.

Conclusions

TiO2–NH2 NPs were successfully cross-linked to the PAN/MWCNT composite nanofibers. This study demonstrated that the fabricated composite nanofibers PAN-MWCNT/TiO2–NH2 is an effective photocatalyst for the degradation of IBP, NPX, and CIZ in aqueous solutions under UV-light. Operational parameters, such as initial drug concentration, catalyst amount, irradiation time, and solution pH were investigated. It was shown that the complete degradation can be achieved at low drug concentration (5 mg/L), acidic pH = 2, and at a low power intensity of the UV lamp (40 Watt). The complete photodegradation of IBP, NPX, and CIZ required 120, 40, and 25 min, respectively. The stability studies showed that the photodegradation efficiency of PAN-MWCNT/TiO2–NH2 composite nanofibers remained stable under the experimental conditions studied.

Abbreviations

- IBP:

-

Ibuprofen

- NPX:

-

Naproxen

- CIZ:

-

Cetirizine

- PAN:

-

Polyacrylonitrile

- TiO2 :

-

titanium dioxide

- MWCNT:

-

multi-walled carbon nanotube

- UV:

-

ultraviolet

- APTES:

-

3-aminopropyltriethoxysilane

- GA:

-

Glutaraldehyde

- DMF:

-

dimethylformamide

- HCI:

-

hydrochloric acid

- NaOH:

-

sodium hydroxide

- SEM:

-

Scanning Electron Microscopy

- FTIR:

-

Fourier transform infrared spectroscopy

- XRD:

-

X-ray diffractometry

References

Georgaki I, Vasilaki E, Katsarakis N (2014) A study on the degradation of carbamazepine and ibuprofen by TiO2 & ZnO photocatalysis upon UV/visible-light irradiation. Am J Anal Chem 5(8):17

Wohde Manuel, Berkner Silvia, Junker Thomas, Konradi Sabine, Schwarz Lisa, Düring Rolf-Alexander (2016) Occurrence and transformation of veterinary pharmaceuticals and biocides in manure: a literature review. Environ Sci Europe 28(1):23

Czech Bożena, Buda Waldemar (2015) Photocatalytic treatment of pharmaceutical wastewater using new multiwall-carbon nanotubes/TiO2/SiO2 nanocomposites. Environ Res 137:176–184

Henneberg Anja, Triebskorn Rita (2015) Efficiency of advanced wastewater treatment technologies for the reduction of hormonal activity in effluents and connected surface water bodies by means of vitellogenin analyses in rainbow trout (Oncorhynchus mykiss) and brown trout (Salmo trutta f. fario). Environ Sci Europe 27(1):22

Achilleos A, Hapeshi E, Xekoukoulotakis NP, Mantzavinos D, Fatta-Kassinos D (2010) UV-A and solar photodegradation of ibuprofen and carbamazepine catalyzed by TiO2. Sep Sci Technol 45(11):1564–1570

Choina J, Kosslick H, Fischer C, Flechsig GU, Frunza L, Schulz A (2013) Photocatalytic decomposition of pharmaceutical ibuprofen pollutions in water over titania catalyst. Appl Cataly B 129:589–598

Begum Shamima, Ahmaruzzaman Md (2018) Biogenic synthesis of SnO2/activated carbon nanocomposite and its application as photocatalyst in the degradation of naproxen. Appl Surf Sci 449:780–789

Luo S, Gao L, Wei Z, Spinney R, Dionysiou DD, Wei-Ping H, Chai L, Xiao R (2018) Kinetic and mechanistic aspects of hydroxyl radical-mediated degradation of naproxen and reaction intermediates. Water Res 137:233–241

Ray SK, Dhakal D, Lee SW (2018) Rapid degradation of naproxen by AgBr-α-NiMoO4 composite photocatalyst in visible light: mechanism and pathways. Chem Eng J 347:836–848

Mohamed A, Yousef S, Abdelnaby MA, Osman TA, Hamawandi B, Toprak MS, Muhammed M, Uheida A (2017) Photocatalytic degradation of organic dyes and enhanced mechanical properties of PAN/CNTs composite nanofibers. Sep Purif Technol 182:219–223

Aboamera NM, Mohamed A, Salama A, Osman TA, Khattab A (2017) Characterization and mechanical properties of electrospun cellulose acetate/graphene oxide composite nanofibers. Mech Adv Mater Struc 4:1–5

Sharifi-Bonab M, Rad FA, Mehrabad JT (2016) Preparation of laccase-graphene oxide nanosheet/alginate composite: application for the removal of cetirizine from aqueous solution. J Environ Chem Eng 4(3):3013–3020

Sutar Rahul S, Rathod Virendra K (2015) Ultrasound assisted enzyme catalyzed degradation of Cetirizine dihydrochloride. Ultrason Sonochem 24:80–86

Mohamed A, El-Sayed R, Osman TA, Toprak MS, Muhammed M, Uheida A (2016) Composite nanofibers for highly efficient photocatalytic degradation of organic dyes from contaminated water. Environ Res 145:18–25

Mohamed A, Mohamed A, Karim SA, Khattab A, Osman T (2018) Preparation, characterization, and mechanical properties of polyacrylonitrile (PAN)/graphene oxide (GO) nanofibers. Mech Adv Mater Struc. https://doi.org/10.1080/15376494.2018.1473535

Mohamed A, Osman TA, Toprak MS, Muhammed M, Yilmaz E, Uheida A (2016) Visible light photocatalytic reduction of Cr (VI) by surface modified CNT/titanium dioxide composites nanofibers. J Mol Catal A 424:45–53

Mohamed A, Nasser WS, Osman TA, Toprak MS, Muhammed M, Uheida A (2017) Removal of chromium (VI) from aqueous solutions using surface modified composite nanofibers. J Coll Interface Sci 505:682–691

Salama A, Mohamed A, Aboamera NM, Osman T, Khattab A (2018) Characterization and mechanical properties of cellulose acetate/carbon nanotube composite nanofibers. Adv Polym Technol 37(7):2446–2451. https://doi.org/10.1002/adv.21919

Yazdi MG, Ivanic M, Mohamed A, Uheida A (2018) Surface modified composite nanofibers for the removal of indigo carmine dye from polluted water. RSC Adv 8(43):24588–24598

Aboamera NM, Mohamed A, Salama A, Osman TA, Khattab A (2018) An effective removal of organic dyes using surface functionalized cellulose acetate/graphene oxide composite nanofibers. Cellulose 25(7):4155–4166

Bundschuh Mirco, Filser Juliane, Lüderwald Simon, McKee Moira S, Metreveli George, Schaumann Gabriele E, Schulz Ralf, Wagner Stephan (2018) Nanoparticles in the environment: where do we come from, where do we go to? Environ Sci Europe 30(1):6

Khalil W, Mohamed A, Bayoumi M, Osman TA (2016) Tribological properties of dispersed carbon nanotubes in lubricant. Fuller Nanotubes Carbon Nanostruct 24(7):479–485

Kamel BM, Mohamed A, El Sherbiny M, Abed KA (2016) Tribological behaviour of calcium grease containing carbon nanotubes additives. Ind Lubr Tribol 68(6):723–728

Karim SA, Mohamed A, Abdel-Mottaleb MM, Osman TA, Khattab A (2018) Mechanical properties and the characterization of polyacrylonitrile/carbon nanotube composite nanofiber. Arab J Sci Eng 43(9):4697–4702

Mohamed A, Osman TA, Toprak MS, Muhammed M, Uheida A (2017) Surface functionalized composite nanofibers for efficient removal of arsenic from aqueous solutions. Chemosphere 180:108–116

Mohamed A, Ghobara MM, Abdelmaksoud MK, Mohamed GG (2019) A novel and highly efficient photocatalytic degradation of malachite green dye via surface modified polyacrylonitrile nanofibers/biogenic silica composite nanofibers. Sep Purif Technol 210:935–942

Mohamed A, Osman TA, Khattab A, Zaki M (2015) Tribological behavior of carbon nanotubes as an additive on lithium grease. J Tribol 137(1):011801

Mohamed A, Osman TA, Khattab A, Zaki M (2013) Rheological behavior of carbon nanotubes as an additive on lithium grease. J Nanotechnol 2013:4

Karim SA, Mohamed A, Abdel-Mottaleb MM, Osman TA, Khattab A (2019) Visible light photocatalytic activity of PAN-CNTs/ZnO-NH2 electrospun nanofibers. J Alloys Compd 772:650–655

Li, Yuanyuan, Qimei Yang, Zhongming Wang, Guoyu Wang, Bin Zhang, Qian Zhang, and Dingfeng Yang, Rapid fabrication of SnO2 nanoparticle photocatalyst: computational understanding and photocatalytic degradation of organic dye. Inorganic Chemistry Frontiers, 2018

Li Y, Yang Q, Wang Z, Wang G, Zhang B, Zhang Q, Yang D (2016) Rapid fabrication of SnO2 nanoparticle photocatalyst: computational understanding and photocatalytic degradation of organic dye. Inorganic Chem Front 150:139–144

Madhavan Jagannathan, Grieser Franz, Ashokkumar Muthupandian (2010) Combined advanced oxidation processes for the synergistic degradation of ibuprofen in aqueous environments. J Hazard Mater 178(1):202–208

Méndez-Arriaga F, Torres-Palma RA, Pétrier C, Esplugas S, Gimenez J, Pulgarin C (2008) Ultrasonic treatment of water contaminated with ibuprofen. Water Res 42(16):4243–4248

Zhang Xu, Feng Wu, XuWei Wu, Chen Pengyu, Deng Nansheng (2008) Photodegradation of acetaminophen in TiO2 suspended solution. J Hazard Mater 157(2):300–307

Sielser HW (1977) Polymer-solvent interaction: the IR-dichroic behaviour of DMF residues in drawn films of polyacrylonitrile. Colloid Polym Sci 255(4):321–326

Yousef Samy, Mohamed Alaa (2016) Mass production of CNTs using CVD multi-quartz tubes. J Mech Sci Technol 30(11):5135–5141

Avila M, Burks T, Akhtar F, Göthelid M, Lansåker PC, Toprak MS, Muhammed M, Uheida A (2014) Surface functionalized nanofibers for the removal of chromium(VI) from aqueous solutions. Chem Eng J 245:201–209

Salama A, Mohamed A, Aboamera NM, Osman TA, Khattab A (2018) Photocatalytic degradation of organic dyes using composite nanofibers under UV irradiation. Appl Nanosci 8(1–2):155–161

Authors’ contributions

AM, AS, and WN conceived, designed, and performed the experiments; AM and AS analyzed the data and wrote the paper; AU reviewed, edited, and approved the manuscript. All authors read and approved the final manuscript.

Acknowledgements

Not applicable

Competing interests

The authors declare that they have no competing interests

Availability of data and materials

Not applicable.

Consent for publication

All authors are aware of the submission and agree to its publication.

Ethics approval and consent to participate

Not applicable.

Funding

Not applicable.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mohamed, A., Salama, A., Nasser, W.S. et al. Photodegradation of Ibuprofen, Cetirizine, and Naproxen by PAN-MWCNT/TiO2–NH2 nanofiber membrane under UV light irradiation. Environ Sci Eur 30, 47 (2018). https://doi.org/10.1186/s12302-018-0177-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12302-018-0177-6