Abstract

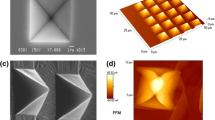

Photolithographic micropatterning is used to achieve topographic rather than chemical control of the static shape and position of microdrops on solid substrates in a gaseous ambient. Micrometer cross-section, millimeter-diameter circular rings with steep sidewalls strongly and robustly pin contact lines of nanoliter to 100 μl liquid drops, increasing the maximum stable drop volume and eliminating contact line motion due to transient accelerations. Physical and chemical processes involving two-phase transport within these drops are more reproducible, and automated image analysis of the evolving drop contents is greatly simplified. This technique has particular promise for high-throughput protein solution screening in structural genomics and drug discovery.

Similar content being viewed by others

References

Abbott NL, Folkers JP, Whitesides GM (1992) Manipulation of the wettability of surfaces on the 0.1-micrometer to 1-micrometer scale through micromachining and molecular self-assembly. Science 257:1380–1382

Berejnov V, Thorne RE (2005) Enhancing drop stability in protein crystallization by chemical patterning. Acta Crystallogr B 61:1563–1567

de Gennes P-G, Brochard-Wyart F, Quere D (2004) Capillarity and wetting phenomena: drops, bubbles, pearls, Waves. Springer, New York

Dyson DC (1988) Contact line stability at edges—comments on Gibbs inequalities. Phys Fluids 31:229–232

Eriksson J, Tiberg F, Zhmud B (2001) Wetting effects due to surfactant carryover through the three-phase contact line. Langmuir 17:7274–7279

Hansen CL, Skordalakes E, Berger JM, Quake SR (2002) A robust and scalable microfluidic metering method that allows protein crystal growth by free interface diffusion. Proc Natl Acad Sci USA 99:16531–16536

Huh C, Mason SG (1977) Effects of surface-roughness on wetting. J Colloid Interface Sci 60:11–38

Jackman RJ, Duffy DC, Ostuni E, Willmore ND, Whitesides GM (1998) Fabricating large arrays of microwells with arbitrary dimensions and filling them using discontinuous dewetting. Anal Chem 70:2280–2287

Johnson RE, Dettre RH (1964) Contact angle hysteresis 1. Study of an idealized rough surface. In: Fowkes FM (ed) Contact angle, wettability, and adhesion. American Chemical Society, Washington, D.C

Oliver JF, Huh C, Mason SG (1977) Resistance to spreading of liquids by sharp edges. J Colloid Interface Sci 59:568–581

Rosen MJ (1978) Surfactants and interfacial phenomena. Wiley, New York

Schena M (2000) Microarray biochip technology. Eaton Publishing, Natick

Shafrin EG, Zisman WA (1964) Upper limits to the contact angles of liquids on solids. In: Fowkes FM (ed) Contact angle, wettability, and adhesion. American Chemical Society, Washington, DC

Shuttleworth R, Bailey GLJ (1948) The spreading of a liquid over a rough solid. Disc Faraday Soc 3:16–22

Stevens RC (2000) High-throughput protein crystallization. Curr Opin Struct Biol 10:558–563

Yang JT, Chen JC, Huang KJ, Yeh JA (2006) Droplet manipulation on a hydrophobic textured surface with roughened patterns. J Microelectromech Sys 15:697–707

Zheng B, Roach LS, Ismagilov RF (2003) Screening of protein crystallization conditions on a microfluidic chip using nanoliter-size droplets. J Am Chem Soc 125:11170–11171

Acknowledgments

We thank Gary Bordonaro, Mike Skavarla and Karlis Musa for their help in fabricating the rings and Anas Abou-Ismail and Robin Baur for evaluating their performance.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was funded by the National Institutes of Health (R01 GM65981).

Rights and permissions

About this article

Cite this article

Kalinin, Y., Berejnov, V. & Thorne, R.E. Controlling microdrop shape and position for biotechnology using micropatterned rings. Microfluid Nanofluid 5, 449–454 (2008). https://doi.org/10.1007/s10404-008-0272-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-008-0272-x