Frontiers of Chemical Science and Engineering ( IF 4.5 ) Pub Date : 2019-09-23 , DOI: 10.1007/s11705-019-1836-x Chi Him Alpha Tsang , Adilet Zhakeyev , Dennis Y. C. Leung , Jin Xuan

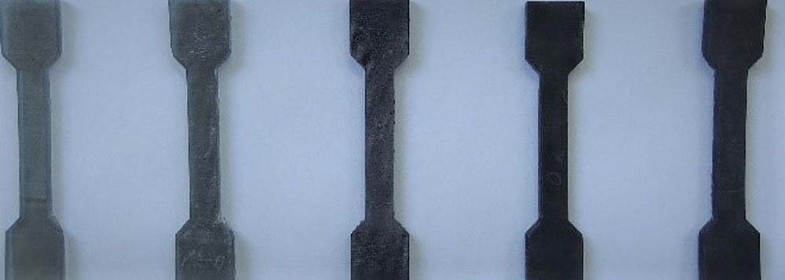

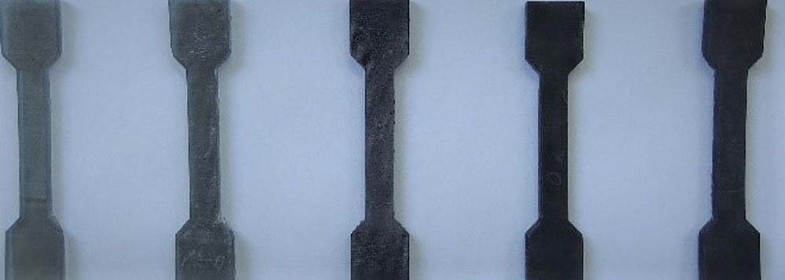

Graphene oxide (GO) induced enhancement of elastomer properties showed a great deal of potential in recent years, but it is still limited by the barrier of the complicated synthesis processes. Stereolithography (SLA), used in fabrication of thermosets and very recently in “flexible” polymers with elastomeric properties, presents itself as simple and user-friendly method for integration of GO into elastomers. In this work, it was first time demonstrated that GO loadings can be incorporated into commercial flexible photopolymer resins to successfully fabricate GO/elastomer nanocomposites via readily accessible, consumer-oriented SLA printer. The material properties of the resulting polymer was characterized and tested. The mechanical strength, stiffness, and the elongation of the resulting polymer decreased with the addition of GO. The thermal properties were also adversely affected upon the increase in the GO content based on differential scanning calorimetry and thermogravimetric analysis results. It was proposed that the GO agglomerates within the 3D printed composites, can result in significant change in both mechanical and thermal properties of the resulting nanocomposites. This study demonstrated the possibility for the development of the GO/elastomer nanocomposites after the optimization of the GO/“flexible” photoreactive resin formulation for SLA with suitable annealing process of the composite in future.

中文翻译:

通过3D立体光刻技术制造的GO改性柔性聚合物纳米复合材料

近年来,氧化石墨烯(GO)诱导的弹性体性能增强潜力巨大,但仍受复杂的合成工艺障碍的限制。立体光刻(SLA)用于制造热固性塑料,最近用于具有弹性的“柔性”聚合物中,它本身就是将GO集成到弹性体中的简单易用的方法。在这项工作中,首次证明可以通过易于使用的,面向消费者的SLA印刷机,将GO填料掺入商业柔性光敏聚合物树脂中,以成功地制造GO /弹性体纳米复合材料。对所得聚合物的材料性能进行了表征和测试。随着GO的加入,所得聚合物的机械强度,刚度和伸长率降低。根据差示扫描量热法和热重分析结果,GO含量的增加也对热性能产生不利影响。有人提出,3D打印复合材料中的GO附聚物会导致所得纳米复合材料的机械和热性能发生重大变化。这项研究表明,在将来通过复合材料的合适退火工艺优化用于SLA的GO /“柔性”光反应性树脂配方后,可以开发GO /弹性体纳米复合材料。会导致所得纳米复合材料的机械和热性能发生重大变化。这项研究表明,在将来通过复合材料的合适退火工艺优化用于SLA的GO /“柔性”光反应性树脂配方后,可以开发GO /弹性体纳米复合材料。会导致所得纳米复合材料的机械和热性能发生重大变化。这项研究表明,在将来通过复合材料的合适退火工艺优化用于SLA的GO /“柔性”光反应性树脂配方后,可以开发GO /弹性体纳米复合材料。

京公网安备 11010802027423号

京公网安备 11010802027423号