ISIJ International ( IF 1.8 ) Pub Date : 2021-10-15 , DOI: 10.2355/isijinternational.isijint-2021-245 Kenichi Mori 1 , Shohtaroh Hashimoto 1 , Mitsuo Miyahara 2

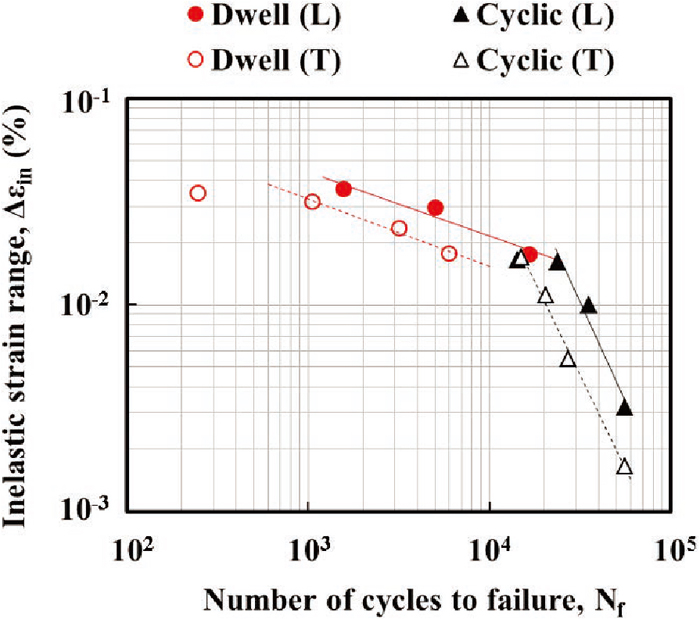

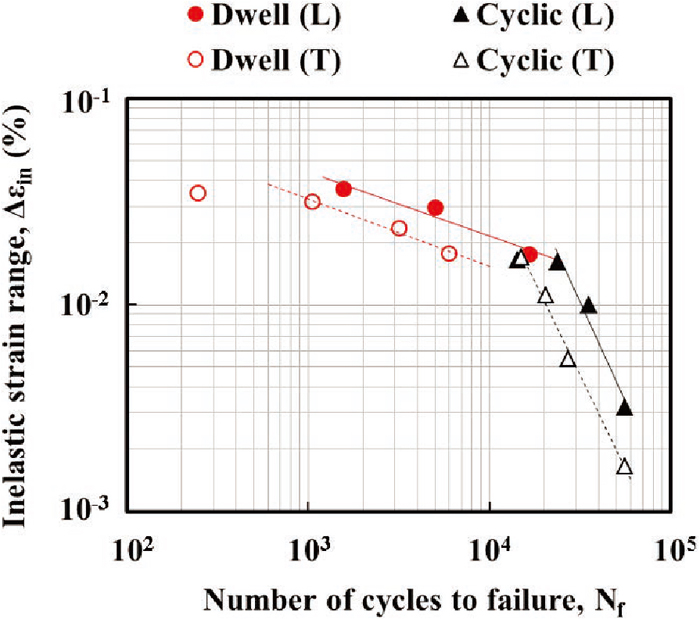

Cyclic fatigue, dwell fatigue and crack growth properties were evaluated in the axial direction (L) and transversal direction (T) of Ti-6Al-4V forged round bar. In the SN curve where the stress is normalized by 0.2% proof stress, the cyclic fatigue life in the L/T direction is almost the same, whereas the dwell fatigue life in the T direction is as short as 1/5. In dwell fatigue, ductile fracture occurred when the maximum stress was higher than 95% of 0.2% proof stress. At stresses below 870 MPa, the inelastic strain range and the strain increase rate in the T direction gradually decreased with decreasing stress, and the fracture mode transitioned to that with fatigue crack growth. The gradual change must have been caused by the mixture of anisotropic microtexture regions. At stresses below 825 MPa, the fracture mode transitioned rapidly in the L direction, where the soft oriented microtexture regions were dominant. In the low ΔK region (≤15 MPa√m), the crack growth rate in the axial direction was about twice that in the radial direction of the bar. The shorter dwell fatigue life in the T direction under stress conditions showing fatigue crack growth was explained by the significantly earlier crack initiation compared to that in cyclic fatigue and the faster crack growth along the microtexture in the axial direction of the bar.

Fullsize Image

Fullsize Image

中文翻译:

微观结构各向异性对 Ti-6Al-4V 棒材驻留疲劳寿命的影响

在 Ti-6Al-4V 锻造圆棒的轴向 (L) 和横向 (T) 上评估循环疲劳、保压疲劳和裂纹扩展性能。在用0.2%屈服应力归一化应力的SN曲线中,L/T方向的循环疲劳寿命几乎相同,而T方向的保压疲劳寿命短至1/5。在驻留疲劳中,当最大应力高于 0.2% 屈服强度的 95% 时,发生延性断裂。当应力低于870 MPa时,T方向的非弹性应变范围和应变增加率随着应力的减小而逐渐减小,断裂模式转变为疲劳裂纹扩展。逐渐变化一定是由各向异性微纹理区域的混合引起的。在应力低于 825 MPa 时,断裂模式在 L 方向快速转变,其中软取向的微观纹理区域占主导地位。在低 ΔK区(≤15 MPa√m),轴向裂纹扩展速率约为钢筋径向裂纹扩展速率的两倍。在显示疲劳裂纹扩展的应力条件下,T 方向上较短的保压疲劳寿命可以解释为与循环疲劳相比,裂纹萌生明显更早,并且沿钢筋轴向微观组织的裂纹扩展更快。

全尺寸图像

全尺寸图像

京公网安备 11010802027423号

京公网安备 11010802027423号