Abstract

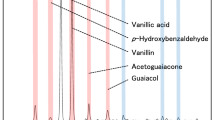

The preparation of vanillin from lignin is one of the lignin valorization strategies. However, obtaining high vanillin yield is still a challenge. Therefore, the process of vanillin production and factors that affect yield of vanillin has attracted much attention. Here, oxidation of vanillin was performed to study its degradation behavior under lignin alkaline oxidation conditions. High-performance liquid chromatography, liquid chromatography–electrospray mass spectrometry, gas chromatography–mass spectrometer and gel permeation chromatography were employed to analyze the products including monomers and dimers. Results demonstrated that reaction temperature and time greatly affected vanillin degradation; vanillin can be completely converted in 5 h at 160 °C. At 160 °C, the main products of vanillin oxidation were small molecule acids and alcohols, other monophenols, and even condensed dimers. A possible vanillin degradation pathway was proposed. The results indicate that vanillin degradation and condensation are the main reasons for decreasing vanillin yield during lignin valorization under alkaline oxidation circumstances.

Similar content being viewed by others

References

Van den Bosch S, Schutyser W, Vanholme R, Driessen T, Koelewijn SF, Renders T, De Meester B, Huijgen WJJ, Dehaen W, Courtin CM, Lagrain B, Boerjan W, Sels BF (2015) Reductive lignocellulose fractionation into soluble lignin-derived phenolic monomers and dimers and processable carbohydrate pulps. Energy Environ Sci 8(6):1748–1763. https://doi.org/10.1039/c5ee00204d

Renders T, Van den Bosch S, Koelewijn S-F, Schutyser W, Sels BF (2017) Lignin-first biomass fractionation, the advent of active stabilisation strategies. Energy Environ Sci 10(7):1551–1557. https://doi.org/10.1039/C7EE01298E

Song Q, Wang F, Cai JY, Wang YH, Zhang JJ, Yu WQ, Xu J (2013) Lignin depolymerization (LDP) in alcohol over nickel-based catalysts via a fragmentation–hydrogenolysis process. Energy Environ Sci 6(3):994–1028. https://doi.org/10.1039/c2ee23741e

Deng HB, Lin L, Sun Y, Pang CS, Zhuang JP, Ouyang PK, Li JJ, Liu SJ (2009) Activity and stability of perovskite-type oxide LaCoO3 catalyst in lignin catalytic wet oxidation to aromatic aldehydes process. Energy Fuels 23:19–24. https://doi.org/10.1021/ef8005349

Zakzeski J, Dębczak A, Bruijnincx PCA, Weckhuysen BM (2011) Catalytic oxidation of aromatic oxygenates by the heterogeneous catalyst Co-ZIF-9. Appl Catal A 394(1–2):79–85. https://doi.org/10.1016/j.apcata.2010.12.026

Sales FG, Abreu CAM, Pereira JAFR (2004) Catalytic wet-air oxidation of lignin in a three-phase reactor with aromatic aldehyde production. Braz J Chem Eng 21:211–218. https://doi.org/10.1590/S0104-66322004000200010

Werhan H, Assmann N, von Rohr PR (2013) Lignin oxidation studies in a continuous two-phase flow microreactor. Chem Eng Process 73:29–37. https://doi.org/10.1016/j.cep.2013.06.015

Galkin MV, Smit AT, Subbotina E, Artemenko KA, Bergquist J, Huijgen WJ, Samec JS (2016) Hydrogen-free catalytic fractionation of woody biomass. Chemsuschem 9(23):3280–3287. https://doi.org/10.1002/cssc.201600648

Zakzeski J, Jongerius AL, Weckhuysen BM (2010) Transition metal catalyzed oxidation of Alcell lignin, soda lignin, and lignin model compounds in ionic liquids. Green Chem 12(7):1225–1236. https://doi.org/10.1039/c001389g

Lv W, Si Z, Tian Z, Wang C, Zhang Q, Xu Y, Wang T, Ma L (2017) Synergistic effect of EtOAc/H2O biphasic solvent and Ru/C catalyst for cornstalk hydrolysis residue depolymerization. Acs Sustain Chem Eng 5(4):2981–2993. https://doi.org/10.1021/acssuschemeng.6b02535

Zhang XH, Zhang Q, Wang TJ, Ma LL, Yu YX, Chen LG (2013) Hydrodeoxygenation of lignin-derived phenolic compounds to hydrocarbons over Ni/SiO2–ZrO2 catalysts. Bioresour Technol 134:73–80. https://doi.org/10.1016/j.biortech.2013.02.039

Liu Y, Chen LG, Wang TJ, Zhang Q, Wang CG, Yan JY, Ma LL (2015) One-pot catalytic conversion of raw lignocellulosic biomass into gasoline alkanes and chemicals over LiTaMoO6 and Ru/C in aqueous phosphoric acid. Acs Sustain Chem Eng 3(8):1745–1755. https://doi.org/10.1021/acssuschemeng.5b00256

Li C, Zhao X, Wang A, Huber GW, Zhang T (2015) Catalytic transformation of lignin for the production of chemicals and fuels. Chem Rev 115(21):11559–11624. https://doi.org/10.1021/acs.chemrev.5b00155

Lange H, Decina S, Crestini C (2013) Oxidative upgrade of lignin—recent routes reviewed. Eur Polym J 49(6):1151–1173. https://doi.org/10.1016/j.eurpolymj.2013.03.002

Fache M, Boutevin B, Caillol S (2016) Vanillin production from lignin and its use as a renewable chemical. Acs Sustain Chem Eng 4(1):35–46. https://doi.org/10.1021/acssuschemeng.5b01344

Rautiainen S, Chen J, Vehkamäki M, Repo T (2016) Oxidation of vanillin with supported gold nanoparticles. Top Catal 59(13–14):1138–1142. https://doi.org/10.1007/s11244-016-0633-8

Patil DG, Magdum PA, Nandibewoor ST (2015) Mechanistic investigations of uncatalyzed and ruthenium(III) catalyzed oxidation of vanillin by periodate in aqueous alkaline medium. J Solution Chem 44(6):1205–1223. https://doi.org/10.1007/s10953-015-0341-1

Fache M, Boutevin B, Caillol S (2015) Vanillin, a key-intermediate of biobased polymers. Eur Polym J 68(SI):488–502. https://doi.org/10.1016/j.eurpolymj.2015.03.050

Bomgardner MM (2014) Following many routes to naturally derived vanillin. Chem Eng News 92(6):14–15. https://doi.org/10.1021/cen-09232-bus2

Tarabanko VE, Koropatchinskaya NV, Kudryashev AV, Kuznetsov BN (1995) Influence of lignin origin on the efficiency of the catalytic oxidation of lignin into vanillin and syringaldehyde. Russ Chem Bull 44:367–371. https://doi.org/10.1007/bf00702154

Tomlinson GH, Hibbert H (1936) Studies on lignin and related compounds. XXV. Mechanism of vanillin formation from spruce lignin sulfonic acids in relation to lignin structure. J Am Chem Soc 58:348–353. https://doi.org/10.1021/ja01293a047

Kim JS, Lee YY, Kim TH (2016) A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour Technol 199:42–48. https://doi.org/10.1016/j.biortech.2015.08.085

Behling R, Valange S, Chatel G (2016) Heterogeneous catalytic oxidation for lignin valorization into valuable chemicals: what results? What limitations? What trends? Green Chem 18(7):1839–1854. https://doi.org/10.1039/c5gc03061g

Deng WP, Zhang HX, Wu XJ, Li RS, Zhang QH, Wang Y (2015) Oxidative conversion of lignin and lignin model compounds catalyzed by CeO2-supported Pd nanoparticles. Green Chem 17(11):5009–5018. https://doi.org/10.1039/C5GC01473E

Rodrigues Pinto PC, Borges da Silva EA, Rodrigues AE (2011) Insights into oxidative conversion of lignin to high-added-value phenolic aldehyde. Ind Eng Chem Res 50:741–748. https://doi.org/10.1021/ie102132a

Wu GX, Heitz M, Chornet E (1994) Improved alkaline oxidation process for the production of aldehydes (vanillin and syringaldehyde) from steam-explosion hardwood lignin. Ind Eng Chern Res 33:718–723. https://doi.org/10.1021/ie00027a034

Fargues C, Mathias Á, Silva J, Rodrígues A (1996) Kinetics of vanillin oxidation. Chem Eng Technol 19(2):127–136. https://doi.org/10.1002/ceat.270190206

Sultanov VS, Wallis AFA (1991) Reactivities of guaiacyl and syringyl lignin model phenols towards oxidation with oxygen-alkali. J Wood Chem Technol 11(3):291–305. https://doi.org/10.1080/02773819108050276

Augugliaro V, Camera-Roda G, Loddo V, Palmisano G, Palmisano L, Parrino F, Puma MA (2012) Synthesis of vanillin in water by TiO2 photocatalysis. Appl Catal B 111–112:555–561. https://doi.org/10.1016/j.apcatb.2011.11.007

Bjørsvik H-R (1999) Fine chemicals from lignosulfonates. 1. Synthesis of vanillin by oxidation of lignosulfonates. Org Process Res Dev 3:330–340. https://doi.org/10.1021/op9900028

Tarabanko VE, Petukhov DV, Selyutin GE (2004) New mechanism for the catalytic oxidation of lignin to vanillin. Kinet Catal 45(4):569–577. https://doi.org/10.1023/B:KICA.0000038087.95130.a5

Tarabanko VE, Fomova NA, Kuznetsov BN, Ivanchenko NM, Kudryashev AV (1995) On the mechanism of vanillin formation in the catalytic oxidation of lignin with oxygen. React Kinet Catal Lett 55:161–170. https://doi.org/10.1007/BF02075847

Mathias AL, Rodrigues AB (1995) Production of vanillin by oxidation of pine kraft lignins with oxygen. Holzforschung 49(3):273–278. https://doi.org/10.1515/hfsg.1995.49.3.273

Borges da Silva EA, Zabkova M, Araújo JD, Cateto CA, Barreiro MF, Belgacem MN, Rodrigues AE (2009) An integrated process to produce vanillin and lignin-based polyurethanes from Kraft lignin. Chem Eng Res Des 87(9):1276–1292. https://doi.org/10.1016/j.cherd.2009.05.008

Araújo JDP, Grande CA, Rodrigues AE (2010) Vanillin production from lignin oxidation in a batch reactor. Chem Eng Res Des 88(8):1024–1032. https://doi.org/10.1016/j.cherd.2010.01.021

Klinke HB, Ahring BK, Schmidt S, Thomsen AB (2002) Characterization of degradation products from alkaline wet oxidation of wheat straw. Bioresour Technol 82(1):15–26. https://doi.org/10.1016/S0960-8524(01)00152-3

Fargues C, Mathias Á, Rodrigues A (1996) Kinetics of vanillin production from kraft lignin oxidation. Ind Eng Chem Res 35(1):28–36. https://doi.org/10.1021/ie950267k

Shilpy M, Ehsan MA, Ali TH, Abd Hamid SB, Ali ME (2015) Performance of cobalt titanate towards H2O2 based catalytic oxidation of lignin model compound. Rsc Adv 5(97):79644–79653. https://doi.org/10.1039/c5ra14227j

Lahive CW, Deuss PJ, Lancefield CS, Sun Z, Cordes DB, Young CM, Tran F, Slawin AM, de Vries JG, Kamer PC, Westwood NJ, Barta K (2016) Advanced model compounds for understanding acid-catalyzed lignin depolymerization: identification of renewable aromatics and a lignin-derived solvent. J Am Chem Soc 138(28):8900–8911. https://doi.org/10.1021/jacs.6b04144

Jiang ZC, Zhang H, He T, Lv XY, Yi J, Li JM, Hu CW (2016) Understanding the cleavage of inter- and intramolecular linkages in corncob residue for utilization of lignin to produce monophenols. Green Chem 18(14):4109–4115. https://doi.org/10.1039/c6gc00798h

Yang HT, Xie YM, Zheng X, Pu YQ, Huang F, Meng XZ, Wu WB, Ragauskas A, Yao L (2016) Comparative study of lignin characteristics from wheat straw obtained by soda-AQ and kraft pretreatment and effect on the following enzymatic hydrolysis process. Bioresour Technol 207:361–369. https://doi.org/10.1016/j.biortech.2016.01.123

Froass PM, Ragauskas AJ, J-e Jiang (1996) Chemical structure of residual lignin from kraft pulp. J Wood Chem Technol 16(4):347–365. https://doi.org/10.1080/02773819608545820

Acknowledgements

This work was supported by NSFC (National Natural Science Foundation of China) project (nos. 51476175, 51606205), the National Natural Science Foundation of China (no. 51536009) and Chinese Academy of Sciences “one hundred talented plan” (no. y507y51001).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the Topical Collection “Lignin Chemistry”; edited by Luis Serrano, Rafael Luque, Bert Sels.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhu, Y., Liu, J., Liao, Y. et al. Degradation of Vanillin During Lignin Valorization Under Alkaline Oxidation. Top Curr Chem (Z) 376, 29 (2018). https://doi.org/10.1007/s41061-018-0208-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41061-018-0208-1