Abstract

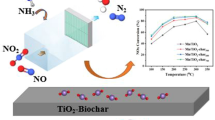

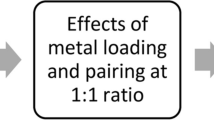

The electrochemical nitrate reduction reaction (NO3RR) to ammonia under ambient conditions is a promising approach for addressing elevated nitrate levels in water bodies, but the progress of this reaction is impeded by the complex series of chemical reactions involving electron and proton transfer and competing hydrogen evolution reaction. Therefore, it becomes imperative to develop an electro-catalyst that exhibits exceptional efficiency and remarkable selectivity for ammonia synthesis while maintaining long-term stability. Herein the magnetic biochar (Fe-C) has been synthesized by a two-step mechanochemical route after a pyrolysis treatment (450, 700, and 1000 °C), which not only significantly decreases the particle size, but also exposes more oxygen-rich functional groups on the surface, promoting the adsorption of nitrate and water and accelerating electron transfer to convert it into ammonia. Results showed that the catalyst (Fe-C-700) has an impressive NH3 production rate of 3.5 mol·h−1·gcat−1, high Faradaic efficiency of 88%, and current density of 0.37 A·cm−2 at 0.8 V vs. reversible hydrogen electrode (RHE). In-situ Fourier transform infrared spectroscopy (FTIR) is used to investigate the reaction intermediate and to monitor the reaction. The oxygen functionalities on the catalyst surface activate nitrate ions to form various intermediates (NO2, NO, NH2OH, and NH2) and reduce the rate determining step energy barrier (*NO3 → *NO2). This study presents a novel approach for the use of magnetic biochar as an electro-catalyst in NO3RR and opens the road for solving environmental and energy challenges.

Similar content being viewed by others

References

Zhang, Y. Z.; Chen, X.; Wang, W. L.; Yin, L. F.; Crittenden, J. C. Electrocatalytic nitrate reduction to ammonia on defective Au1Cu (111) single-atom alloys. Appl. Catal. B: Environ. 2022, 310, 121346.

Chen, F. Y.; Wu, Z. Y.; Gupta, S.; Rivera, D. J.; Lambeets, S. V.; Pecaut, S.; Kim, J. Y. T.; Zhu, P.; Finfrock, Y. Z.; Meira, D. M. et al. Efficient conversion of low-concentration nitrate sources into ammonia on a Ru-dispersed Cu nanowire electrocatalyst. Nat. Nanotechnol. 2022, 17, 759–767.

Chen, G. F.; Yuan, Y. F.; Jiang, H. F.; Ren, S. Y.; Ding, L. X.; Ma, L.; Wu, T. P.; Lu, J.; Wang, H. H. Electrochemical reduction of nitrate to ammonia via direct eight-electron transfer using a copper-molecular solid catalyst. Nat. Energy 2020, 5, 605–613.

Liu, Y. L.; Deng, P. J.; Wu, R. Q.; Zhang, X. L.; Sun, C. H.; Li, H. T. Oxygen vacancies for promoting the electrochemical nitrogen reduction reaction. J. Mater. Chem. A 2021, 9, 6694–6709.

Liu, H. M.; Lang, X. Y.; Zhu, C.; Timoshenko, J.; Rüscher, M.; Bai, L. C.; Guijarro, N.; Yin, H. B.; Peng, Y.; Li, J. H. et al. Efficient electrochemical nitrate reduction to ammonia with copper-supported rhodium cluster and single-atom catalysts. Angew. Chem., Int. Ed. 2022, 61, e202202556.

Liang, J.; Liu, P. Y.; Li, Q. Y.; Li, T. S.; Yue, L. C.; Luo, Y. S.; Liu, Q.; Li, N.; Tang, B.; Alshehri, A. A. et al. Amorphous boron carbide on titanium dioxide nanobelt arrays for high-efficiency electrocatalytic NO reduction to NH3. Angew. Chem., Int. Ed. 2022, 61, e202202087.

Liang, J.; Zhou, Q.; Mou, T.; Chen, H. Y.; Yue, L. C.; Luo, Y. S.; Liu, Q.; Hamdy, M. S.; Alshehri, A. A.; Gong, F. et al. FeP nanorod array: A high-efficiency catalyst for electroreduction of NO to NH3 under ambient conditions. Nano Res. 2022, 15, 4008–4013.

Liang, J.; Li, Z. X.; Zhang, L. C.; He, X.; Luo, Y. S.; Zheng, D. D.; Wang, Y.; Li, T. S.; Yan, H.; Ying, B. W. et al. Advances in ammonia electrosynthesis from ambient nitrate/nitrite reduction. Chem 2023, 9, 1768–1827.

Liu, C. W.; Hao, D.; Ye, J.; Ye, S.; Zhou, F. L.; Xie, H. B.; Qin, G. W.; Xu, J. T.; Liu, J.; Li, S. et al. Knowledge-driven design and lab-based evaluation of B-doped TiO2 photocatalysts for ammonia synthesis. Adv. Energy Mater. 2023, 13, 2204126.

Wang, T. Y.; Guo, Z. Y.; Zhang, X. L.; Li, Q. Y.; Yu, A. M.; Wu, C. Z.; Sun, C. H. Recent progress of iron-based electrocatalysts for nitrogen reduction reaction. J. Mater. Sci. Technol. 2023, 140, 121–134.

Li, Y. X.; Liu, Y. X.; Liu, X.; Liu, Y. L.; Cheng, Y. Y.; Zhang, P.; Deng, P. J.; Deng, J. J.; Kang, Z. H.; Li, H. T. Fe-doped SnO2 nanosheet for ambient electrocatalytic nitrogen reduction reaction. Nano Res. 2022, 15, 6026–6035.

Liu, N. Y.; Wu, R. Q.; Liu, Y. X.; Liu, Y. L.; Deng, P. J.; Li, Y. X.; Du, Y. C.; Cheng, Y. Y.; Zhuang, Z. C.; Kang, Z. H. et al. Oxygen vacancy engineering of Fe-doped NiMoO4 for electrocatalytic N2 fixation to NH3. Inorg. Chem. 2023, 62, 11990–12000.

Liu, Y. L.; Deng, P. J.; Wu, R. Q.; Geioushy, R. A.; Li, Y. X.; Liu, Y. X.; Zhou, F. L.; Li, H. T.; Sun, C. H. BiVO4/TiO2 heterojunction with rich oxygen vacancies for enhanced electrocatalytic nitrogen reduction reaction. Front. Phys. 2021, 16, 53503.

Jia, R. R.; Wang, Y. T.; Wang, C. H.; Ling, Y. F.; Yu, Y. F.; Zhang, B. Boosting selective nitrate electroreduction to ammonium by constructing oxygen vacancies in TiO2. ACS Catal. 2020, 10, 3533–3540.

Wang, Y. H.; Xu, A. N.; Wang, Z. Y.; Huang, L. S.; Li, J.; Li, F. W.; Wicks, J.; Luo, M. C.; Nam, D. H.; Tan, C. S. et al. Enhanced nitrate-to-ammonia activity on copper-nickel alloys via tuning of intermediate adsorption. J. Am. Chem. Soc. 2020, 142, 5702–5708.

Mcenaney, J. M.; Blair, S. J.; Nielander, A. C.; Schwalbe, J. A.; Koshy, D. M.; Cargnello, M.; Jaramillo, T. F. Elcctrolyte engineering for efficient electrochemical nitrate reduction to ammonia on a titanium electrode. ACS Sustain. Chem. Eng. 2020, 8, 2672–2681.

He, W. H.; Zhang, J.; Dieckhöfer, S.; Varhade, S.; Brix, A. C.; Lielpetere, A.; Seisel, S.; Junqueira, J. R. C.; Schuhmann, W. Splicing the active phases of copper/cobalt-based catalysts achieves high-rate tandem electroreduction of nitrate to ammonia. Nat. Commun. 2022, 13, 1129.

Zhang, Y.; Liu, Y. L.; Yu, Q.; Zhang, Q. K.; Si, Z. B.; Li, H. T.; Xu, H. Direct reduction of diluted CO2 gas to C2 products by copper hydroxyphosphate microrods. AIChE J. 2023, 69, e18233.

Sun, P. P.; Chen, Z. G.; Zhang, J. Y.; Wu, G. Y.; Song, Y. H.; Miao, Z. H.; Zhong, K.; Huang, L.; Mo, Z.; Xu, H. Simultaneously tuning electronic reaction pathway and photoactivity of P, O modified cyano-rich carbon nitride enhances the photosynthesis of H2O2. Appl. Catal. B: Environ. 2024, 342, 123337.

Su, X. Z.; Jiang, Z. L.; Zhou, J.; Liu, H. J.; Zhou, D. N.; Shang, H. S.; Ni, X. M.; Peng, Z.; Yang, F.; Chen, W. X. et al. Complementary operando spectroscopy identification of in-situ generated metastable charge-asymmetry Cu2-CuN3 clusters for CO2 reduction to ethanol. Nat. Commun. 2022, 13, 1322.

Wang, G.; Chen, Z.; Wang, T.; Wang, D. S.; Mao, J. J. P and Cu dual sites on graphitic carbon nitride for photocatalytic CO2 reduction to hydrocarbon fuels with high C2H6 evolution. Angew. Chem., Int. Ed. 2022, 61, e202210789.

Wu, Q. L.; Sun, Y.; Zhao, Q.; Li, H.; Ju, Z. N.; Wang, Y.; Sun, X. D.; Jia, B. H.; Qiu, J. S.; Ma, T. Y. Bismuth stabilized by ZIF derivatives for electrochemical ammonia production: Proton donation effect of phosphorus dopants. Nano Res. 2023, 16, 4574–4581.

He, X.; Li, X. H.; Fan, X. Y.; Li, J.; Zhao, D. L.; Zhang, L. C.; Sun, S. J.; Luo, Y. S.; Zheng, D. D.; Xie, L. S. et al. Ambient electroreduction of nitrite to ammonia over Ni nanoparticle supported on molasses-derived carbon sheets. ACS Appl. Nano Mater. 2022, 5, 14246–14250.

Fang, J. Y.; Zheng, Q. Z.; Lou, Y. Y.; Zhao, K. M.; Hu, S. N.; Li, G.; Akdim, O.; Huang, X. Y.; Sun, S. G. Ampere-level current density ammonia electrochemical synthesis using CuCo nanosheets simulating nitrite reductase bifunctional nature. Nat. Commun. 2022, 13, 7899.

Fan, K.; Xie, W. F.; Li, J. Z.; Sun, Y. N.; Xu, P. C.; Tang, Y.; Li, Z. H.; Shao, M. F. Active hydrogen boosts electrochemical nitrate reduction to ammonia. Nat. Commun. 2022, 13, 7958.

Li, X. T.; Shen, P.; Li, X. C.; Ma, D. W.; Chu, K. Sub-nm RuOx clusters on Pd metallene for synergistically enhanced nitrate electroreduction to ammonia. ACS Nano 2023, 17, 1081–1090.

Zhou, Y. Y.; Duan, R. Z.; Li, H.; Zhao, M.; Ding, C. M.; Li, C. Boosting electrocatalytic nitrate reduction to ammonia via promoting water dissociation. ACS Catal. 2023, 13, 10846–10854.

Zhuang, C. Q.; Li, W. M.; Zhang, T. Y.; Li, J. T.; Zhang, Y. H.; Chen, G.; Li, H. T.; Kang, Z. H.; Zou, J.; Han, X. D. Monodispersed aluminum in carbon nitride creates highly efficient nitrogen active sites for ultra-high hydrogen peroxide photoproduction. Nano Energy 2023, 108, 108225.

Li, Y. L.; Zhuang, C. Q.; Qiu, S.; Gao, J. F.; Zhou, Q.; Sun, Z. C.; Kang, Z. H.; Han, X. D. Cs-Cu- Cl perovskite quantum dots for photocatalytic H2 evolution with super-high stability. Appl. Catal. B: Environ. 2023, 337, 122881.

Xie, M. H.; Tang, S. S.; Li, Z.; Wang, M. Y.; Jin, Z. Y.; Li, P. P.; Zhan, X.; Zhou, H.; Yu, G. H. Intermetallic single-atom alloy In-Pd bimetallene for neutral electrosynthesis of ammonia from nitrate. J. Am. Chem. Soc. 2023, 145, 13957–13967.

Fan, X. Y.; Liu, C. Z.; Li, Z. X.; Cai, Z. W.; Ouyang, L.; Li, Z. R.; He, X.; Luo, Y. S.; Zheng, D. D.; Sun, S. J. et al. Pd-doped Co3O4 nanoarray for efficient eight-electron nitrate electrocatalytic reduction to ammonia synthesis. Small 2023, 19, 2303424.

Wang, Y. B.; Qin, Y. T.; Li, W.; Wang, Y. T.; Zhu, L. N.; Zhao, M. T.; Yu, Y. F. Controllable NO release for catheter antibacteria from nitrite electroreduction over the Cu-MOF. Trans. Tianjin Univ. 2023, 29, 275–283.

He, X.; Li, Z. X.; Yao, J.; Dong, K.; Li, X. H.; Hu, L.; Sun, S. J.; Cai, Z. W.; Zheng, D. D.; Luo, Y. S. et al. High-efficiency electrocatalytic nitrite reduction toward ammonia synthesis on CoP@TiO2 nanoribbon array. iScience 2023, 26, 107100.

Ma, G. Y.; Sun, F.; Qiao, L.; Shen, Q. L.; Wang, L.; Tang, Q.; Tang, Z. H. Atomically precise alkynyl-protected Ag20Cu12 nanocluster: Structure analysis and electrocatalytic performance toward nitrate reduction for NH3 synthesis. Nano Res. 2023, 16, 10867–10872.

Fan, X. Y.; Zhao, D. L.; Deng, Z. Q.; Zhang, L. C.; Li, J.; Li, Z. R.; Sun, S. J.; Luo, Y. S.; Zheng, D. D.; Wang, Y. et al. Constructing Co@TiO2 nanoarray heterostructure with Schottky contact for selective electrocatalytic nitrate reduction to ammonia. Small 2023, 19, 2208036.

Zhang, Z. J.; Liu, Y.; Su, X. Z.; Zhao, Z. W.; Mo, Z. K.; Wang, C. Y.; Zhao, Y. L.; Chen, Y.; Gao, S. Y. Electro-triggered Joule heating method to synthesize single-phase CuNi nano-alloy catalyst for efficient electrocatalytic nitrate reduction toward ammonia. Nano Res. 2023, 16, 6632–6641.

Ouyang, L.; Liang, J.; Luo, Y. S.; Zheng, D. D.; Sun, S. J.; Liu, Q.; Hamdy, M. S.; Sun, X. P.; Ying, B. W. Recent advances in electrocatalytic ammonia synthesis. Chin. J. Catal. 2023, 50, 6–44.

Hu, Q.; Qin, Y. J.; Wang, X. D.; Wang, Z. Y.; Huang, X. W.; Zheng, H. J.; Gao, K. R.; Yang, H. P.; Zhang, P. X.; Shao, M. H. et al. Reaction intermediate-mediated electrocatalyst synthesis favors specified facet and defect exposure for efficient nitrate-ammonia conversion. Energy Environ. Sci. 2021, 14, 4989–4997.

Song, W.; Yue, L. C.; Fan, X. Y.; Luo, Y. S.; Ying, B. W.; Sun, S. J.; Zheng, D. D.; Liu, Q.; Hamdy, M. S.; Sun, X. P. Recent progress and strategies on the design of catalysts for electrochemical ammonia synthesis from nitrate reduction. Inorg. Chem. Front. 2023, 10, 3489–3514.

Wang, Y. T.; Li, H. J.; Zhou, W.; Zhang, X.; Zhang, B.; Yu, Y. F. Structurally disordered RuO2 nanosheets with rich oxygen vacancies for enhanced nitrate electroreduction to ammonia. Angew. Chem., Int. Ed. 2022, 61, e202202604.

Zhang, X.; Wang, Y. T.; Liu, C. B.; Yu, Y. F.; Lu, S. Y.; Zhang, B. Recent advances in non-noble metal electrocatalysts for nitrate reduction. Chem. Eng. J. 2021, 403, 126269.

Zhu, H.; Sun, S. H.; Hao, J. C.; Zhuang, Z. C.; Zhang, S. G.; Wang, T. D.; Kang, Q.; Lu, S. L.; Wang, X. F.; Lai, F. L. et al. A high-entropy atomic environment converts inactive to active sites for electrocatalysis. Energy Environ. Sci. 2023, 16, 619–628.

Zhuang, Z. C.; Li, Y. H.; Yu, R. H.; Xia, L. X.; Yang, J. R.; Lang, Z. Q.; Zhu, J. X.; Huang, J. Z.; Wang, J. O.; Wang, Y. et al. Reversely trapping atoms from a perovskite surface for high-performance and durable fuel cell cathodes. Nat. Catal. 2022, 5, 300–310.

Xu, J. W.; Zhang, S. B.; Liu, H. J.; Liu, S.; Yuan, Y.; Meng, Y. H.; Wang, M. M.; Shen, C. Y.; Peng, Q.; Chen, J. H. et al. Breaking local charge symmetry of iron single atoms for efficient electrocatalytic nitrate reduction to ammonia. Angew. Chem., Int. Ed. 2023, 62, e202308044.

Zhang, S.; Wu, J. H.; Zheng, M. T.; Jin, X.; Shen, Z. H.; Li, Z. H.; Wang, Y. J.; Wang, Q.; Wang, X. B.; Wei, H. et al. Fe/Cu diatomic catalysts for electrochemical nitrate reduction to ammonia. Nat. Commun. 2023, 14, 3634.

Li, R. Z.; Wang, D. S. Understanding the structure-performance relationship of active sites at atomic scale. Nano Res. 2022, 15, 6888–6923.

Zheng, X. B.; Li, B. B.; Wang, Q. S.; Wang, D. S.; Li, Y. D. Emerging low-nuclearity supported metal catalysts with atomic level precision for efficient heterogeneous catalysis. Nano Res. 2022, 15, 7806–7839.

Li, Y.; Hua, Y. Q.; Sun, N.; Liu, S. J.; Li, H. X.; Wang, C.; Yang, X. Y.; Zhuang, Z. C.; Wang, L. L. Moiré superlattice engineering of two-dimensional materials for electrocatalytic hydrogen evolution reaction. Nano Res. 2023, 16, 8712–8728.

Hao, J. C.; Zhu, H.; Zhuang, Z. C.; Zhao, Q.; Yu, R. H.; Hao, J. C.; Kang, Q.; Lu, S. L.; Wang, X. F.; Wu, J. S. et al. Competitive trapping of single atoms onto a metal carbide surface. ACS Nano 2023, 17, 6955–6965.

Yin, W. N.; Cai, Y. T.; Xie, L. B.; Huang, H.; Zhu, E. C.; Pan, J. N.; Bu, J. Q.; Chen, H.; Yuan, Y.; Zhuang, Z. C. et al. Revisited electrochemical gas evolution reactions from the perspective of gas bubbles. Nano Res. 2023, 16, 4381–4398.

Luo, H. X.; Li, S. J.; Wu, Z. Y.; Liu, Y. B.; Luo, W.; Li, W.; Zhang, D. Q.; Chen, J.; Yang, J. P. Modulating the active hydrogen adsorption on Fe–N interface for boosted electrocatalytic nitrate reduction with ultra-long stability. Adv. Mater. 2023, 35, 2304695.

Zhao, X. Y.; Jiang, Y. Z.; Wang, M. F.; Liu, S. S.; Wang, Z. C.; Qian, T.; Yan, C. L. Optimizing intermediate adsorption via heteroatom ensemble effect over RuFe bimetallic alloy for enhanced nitrate electroreduction to ammonia. Adv. Energy Mater. 2023, 13, 2301409.

Xian, J. H.; Li, S. S.; Su, H.; Liao, P. S.; Wang, S. H.; Xiang, R. N.; Zhang, Y. W.; Liu, Q. H.; Li, G. Q. Electrosynthesis of α-amino acids from NO and other NOx species over CoFe alloy-decorated self-standing carbon fiber membranes. Angew. Chem., Int. Ed. 2023, 62, e202306726.

Hao, R.; Fang, S. S.; Tian, L.; Xia, R. L.; Guan, Q. X.; Jiao, L. F.; Liu, Y. P.; Li, W. Elucidation of the electrocatalytic activity origin of Fe3C species and application in the NOx full conversion to valuable ammonia. Chem. Eng. J. 2023, 467, 143371.

Wang, J.; Wang, Y. A.; Cai, C.; Liu, Y. S.; Wu, D. J.; Wang, M. Y.; Li, M. H.; Wei, X. B.; Shao, M. H.; Gu, M. Cu-doped iron oxide for the efficient electrocatalytic nitrate reduction reaction. Nano Lett. 2023, 23, 1897–1903.

Akram, M. A.; Zhu, B. T.; Cai, J. H.; Qin, S. B.; Hou, X. D.; Jin, P.; Wang, F.; He, Y. P.; Li, X. H.; Feng, L. Hierarchical nanospheres with polycrystalline Ir&Cu and amorphous Cu2O toward energy-efficient nitrate electrolysis to ammonia. Small 2023, 19, 2206966.

Zhang, N. N.; Zhang, G. K.; Shen, P.; Zhang, H.; Ma, D. W.; Chu, K. Lewis acid Fe–V pairs promote nitrate electroreduction to ammonia. Adv. Funct. Mater. 2023, 33, 2211537.

Zhang, S.; Li, M.; Li, J. C.; Song, Q. N.; Liu, X. N-doped carbon–iron heterointerfaces for boosted electrocatalytic active and selective ammonia production. Proc. Natl. Acad. Sci. USA 2023, 120, e2207080119.

Zhang, H.; Wang, C. Q.; Luo, H. X.; Chen, J. L.; Kuang, M.; Yang, J. P. Iron nanoparticles protected by chainmail-structured graphene for durable electrocatalytic nitrate reduction to nitrogen. Angew. Chem., Int. Ed. 2023, 62, e202217071.

Reichle, S.; Felderhoff, M.; Schüth, F. Mechanocatalytic room-temperature synthesis of ammonia from its elements down to atmospheric pressure. Angew. Chem., Int. Ed. 2021, 60, 26385–26389.

Zhou, D. J.; Wang, S. Y.; Jia, Y.; Xiong, X. Y.; Yang, H. B.; Liu, S.; Tang, J. L.; Zhang, J. M.; Liu, D.; Zheng, L. R. et al. NiFe hydroxide lattice tensile strain: Enhancement of adsorption of oxygenated intermediates for efficient water oxidation catalysis. Angew. Chem., Int. Ed. 2019, 58, 736–740.

Xia, H. S.; Wang, Z. H. Piezoelectricity drives organic synthesis. Science 2019, 366, 1451–1452.

Kubota, K.; Pang, Y. D.; Miura, A.; Ito, H. Redox reactions of small organic molecules using ball milling and piezoelectric materials. Science 2019, 366, 1500–1504.

Jin, T.; Wang, J. T.; Gong, Y.; Zheng, Q.; Wang, T. X.; Wu, R. Q.; Lyu, Y.; Liu, X. F. Mechanochemical- tuning size dependence of iridium single atom and nanocluster toward highly selective ammonium production. Chem Catal. 2023, 3, 100477.

Yan, N. N.; Hu, B.; Zheng, Z. Y.; Lu, H. Y.; Chen, J. W.; Zhang, X. M.; Jiang, X. Z.; Wu, Y. H.; Dolfing, J.; Xu, L. Twice-milled magnetic biochar: A recyclable material for efficient removal of methylene blue from wastewater. Bioresour. Technol. 2023, 372, 128663.

Liu, Z. H.; Du, Y.; Zhang, P. F.; Zhuang, Z. C.; Wang, D. S. Bringing catalytic order out of chaos with nitrogen-doped ordered mesoporous carbon. Matter 2021, 4, 3161–3194.

Jung, E.; Shin, H.; Lee, B. H.; Efremov, V.; Lee, S.; Lee, H. S.; Kim, J.; Hooch Antink, W.; Park, S.; Lee, K. S. et al. Atomic-level tuning of Co-N-C catalyst for high-performance electrochemical H2O2 production. Nat. Mater. 2020, 19, 436–442.

Long, Y. D.; Lin, J. G.; Ye, F. H.; Liu, W.; Wang, D.; Cheng, Q. Q.; Paul, R.; Cheng, D. J.; Mao, B. G.; Yan, R. Q. et al. Tailoring the atomic-local environment of carbon nanotube tips for selective H2O2 electrosynthesis at high current densities. Adv. Mater. 2023, 35, 2303905.

Wang, L. J.; Liu, F. H.; Pal, A.; Ning, Y. S.; Wang, Z.; Zhao, B. Y.; Bradley, R.; Wu, W. P. Ultra-small Fe3O4 nanoparticles encapsulated in hollow porous carbon nanocapsules for high performance supercapacitors. Carbon 2021, 179, 327–336.

Ren, Y. W.; Yu, C.; Wang, L. S.; Tan, X. Y.; Wang, Z.; Wei, Q. B.; Zhang, Y. F.; Qiu, J. S. Microscopic- level insights into the mechanism of enhanced NH3 synthesis in plasma-enabled cascade N2 oxidation-electroreduction system. J. Am. Chem. Soc. 2022, 144, 10193–10200.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 52072152 and 51802126), the Jiangsu University Jinshan Professor Fund, the Jiangsu Specially-Appointed Professor Fund, Open Fund from Guangxi Key Laboratory of Electrochemical Energy Materials, Zhenjiang “Jinshan Talents” Project 2021, China PostDoctoral Science Foundation (No. 2022M721372), “Doctor of Entrepreneurship and Innovation” in Jiangsu Province (No. JSSCBS20221197), the Postgraduate Research & Practice Innovation Program of Jiangsu Province (No. KYCX22_3645), the National Natural Science Foundation of China (No. 22208134), and Jiangsu Agricultural Science and Technology Innovation Fund (No. CX(21)1010).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Liu, Y., Zheng, Z., Jabeen, S. et al. Mechanochemical route to fabricate an efficient nitrate reduction electrocatalyst. Nano Res. (2024). https://doi.org/10.1007/s12274-024-6478-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12274-024-6478-8